Method for perfusing refrigerant into air conditioner

A technology for air conditioners and air conditioner rooms, which is applied in air conditioning systems, refrigerators, heating methods, etc., can solve the problems of reducing compressor life, compressor impact, etc., and achieves the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described below with reference to the accompanying drawings and in combination with specific embodiments.

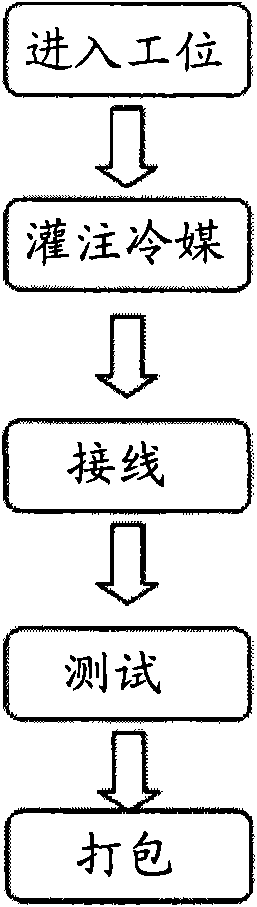

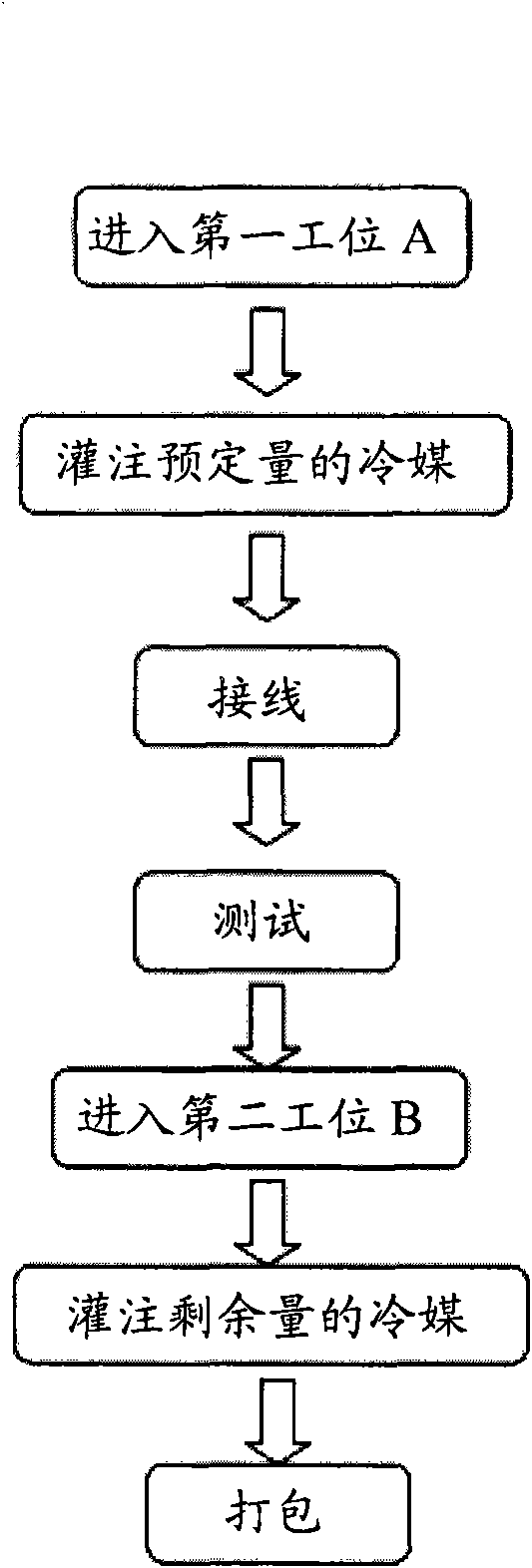

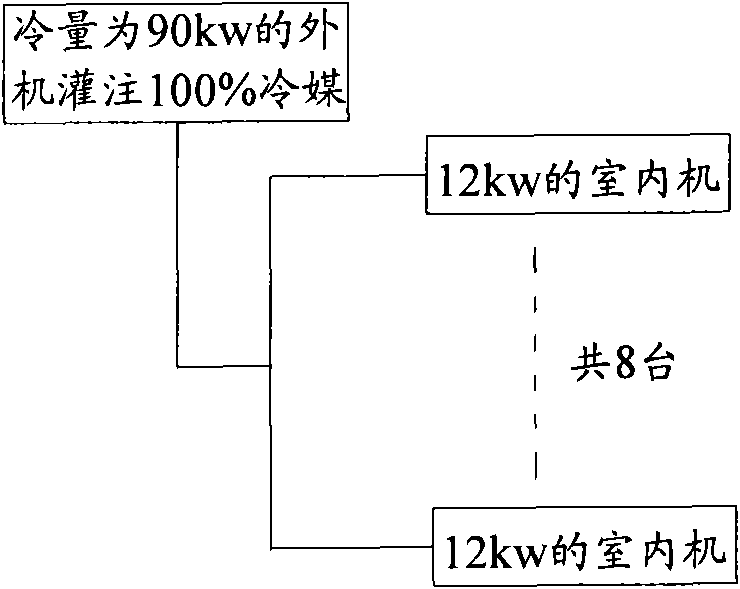

[0027] First refer to figure 2 , which shows the specific implementation steps of the air conditioner refrigerant filling method according to the present invention, in figure 1 In the method shown, a standard amount of refrigerant is poured into the outdoor unit of the air conditioner in two filling steps. The refrigerant filling method includes:

[0028] a) Vacuumize the outdoor unit for subsequent refrigerant filling;

[0029] b) In the first refrigerant filling step (pre-filling step), pouring a predetermined amount of refrigerant (the method for determining the predetermined amount will be described later) into the outdoor unit;

[0030] c) Connect the outdoor unit filled with a predetermined amount of refrigerant to the test circuit for performance testing;

[0031] d) Using the indoor unit of the air condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com