Mechanical failure diagnostic method and device

A technology for mechanical faults and diagnosis methods, applied in the field of automation, can solve problems such as fuzzy similarity and difference, and achieve the effect of improving robustness and accuracy and simplifying the process of fault type identification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

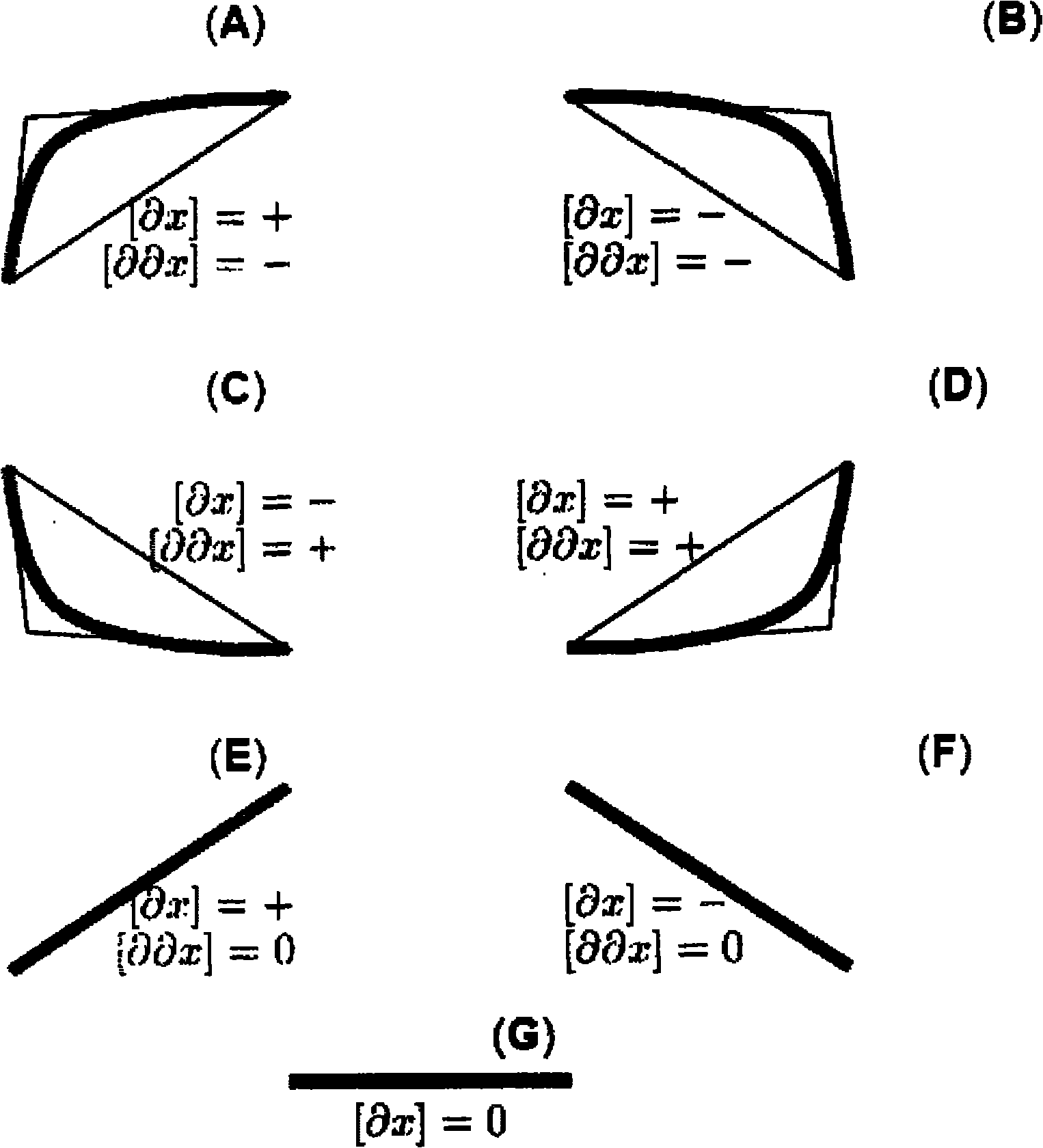

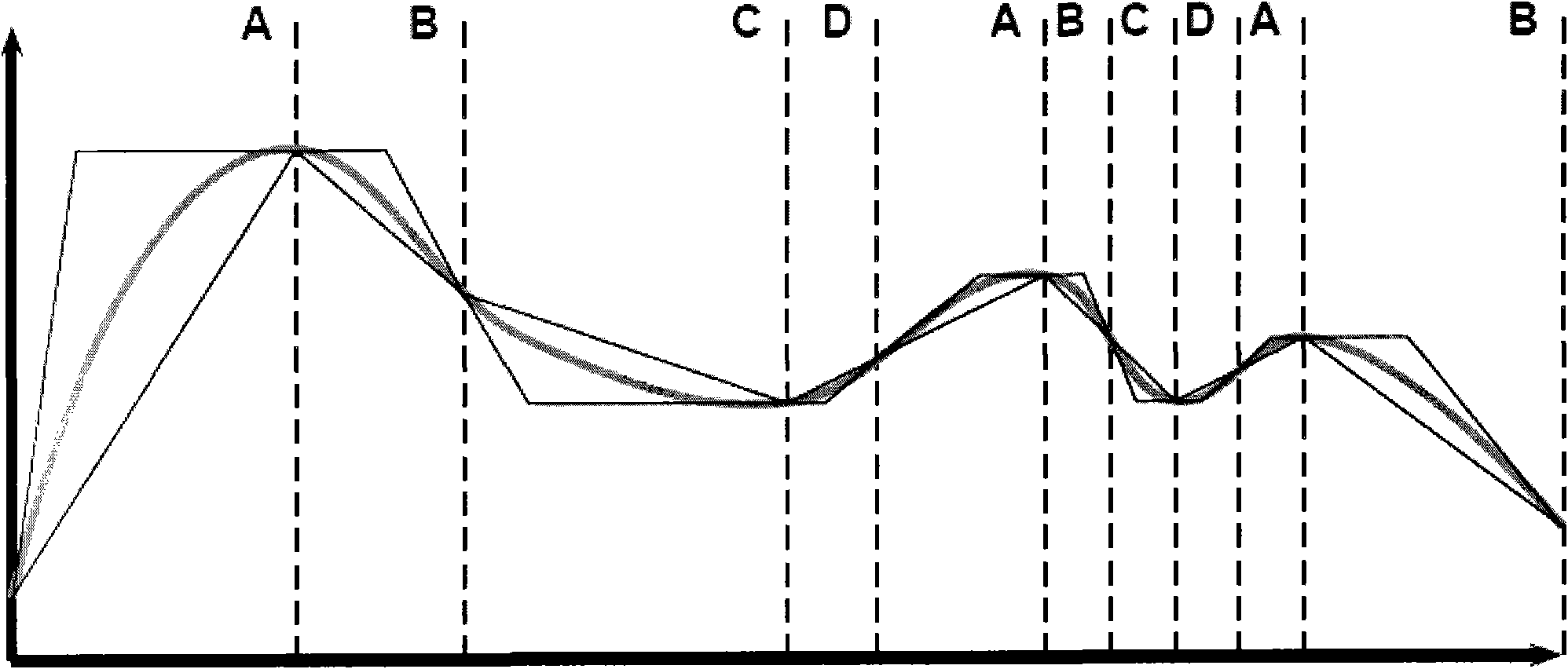

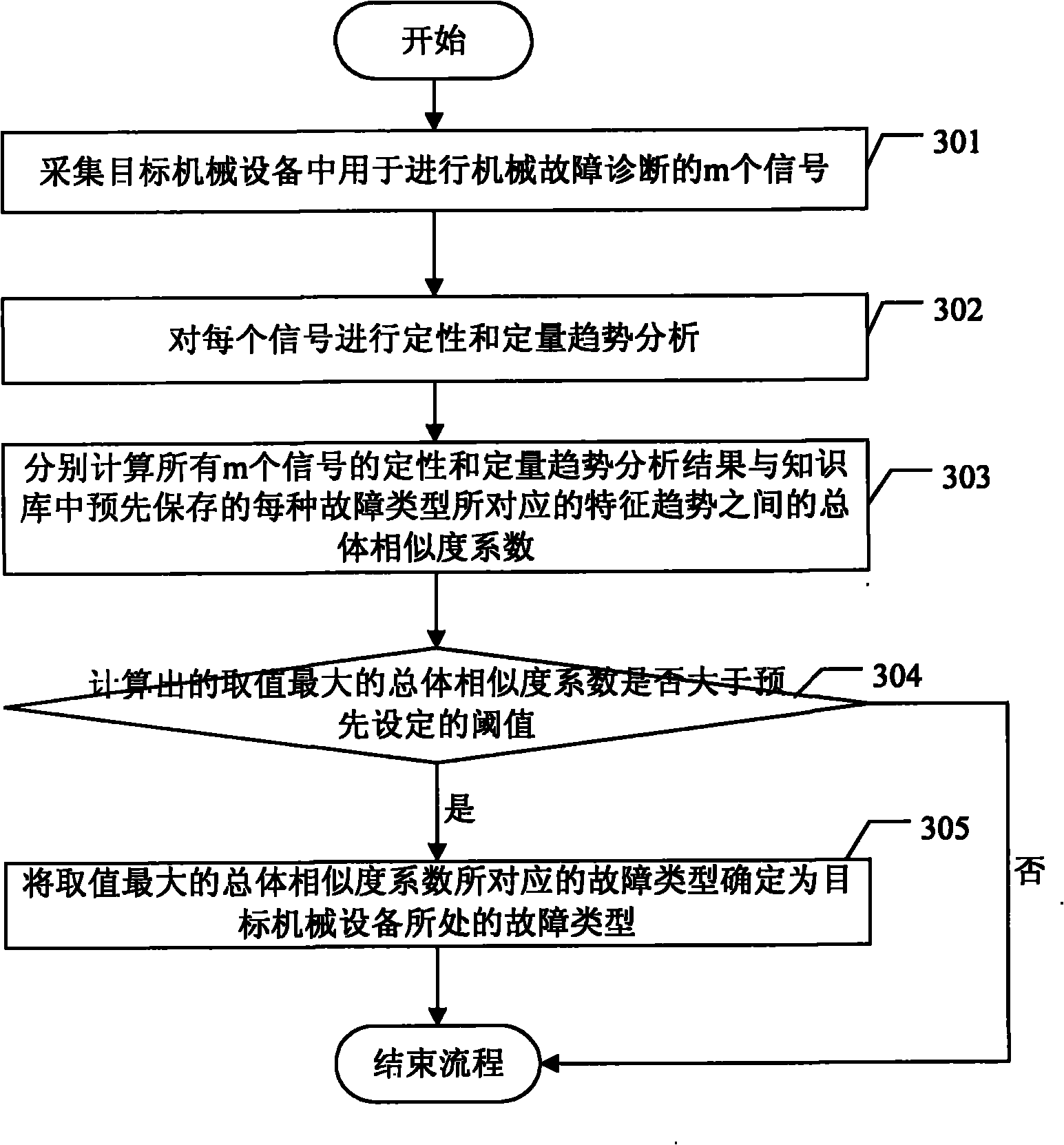

[0078] Aiming at the problems existing in the prior art, the present invention proposes a brand-new mechanical fault diagnosis scheme. Its specific implementation includes: first, collect m signals for mechanical fault diagnosis in the target mechanical equipment, m is a positive integer, and conduct qualitative and quantitative trend analysis on each signal; then, calculate the qualitative and quantitative trends of all m signals respectively and the overall similarity coefficient between the quantitative trend analysis results and the characteristic trend corresponding to each fault type pre-saved in the knowledge base; finally, judge whether the calculated overall similarity coefficient with the largest value is greater than the preset threshold , if yes, determine the fault type corresponding to the overall similarity coefficient with the largest value as the fault type of the target mechanical equipment.

[0079] In order to make the object, technical solution and advanta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com