Cam lever-type large-block material crushing machine

A block material and cam lever technology, applied in the field of mechanical equipment, can solve the problems of high labor intensity and low production efficiency, and achieve the effect of reducing labor intensity, high strike efficiency and low ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

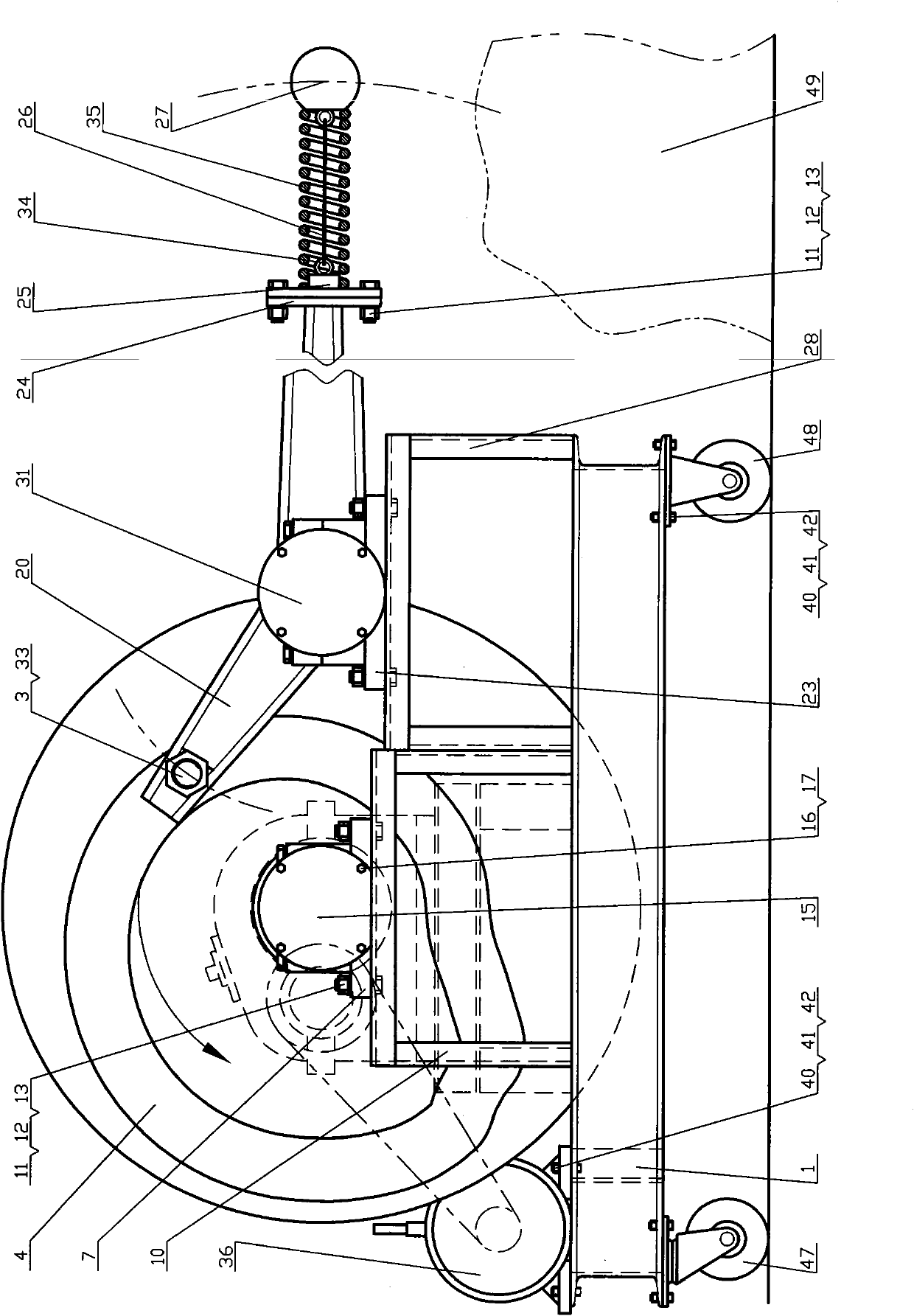

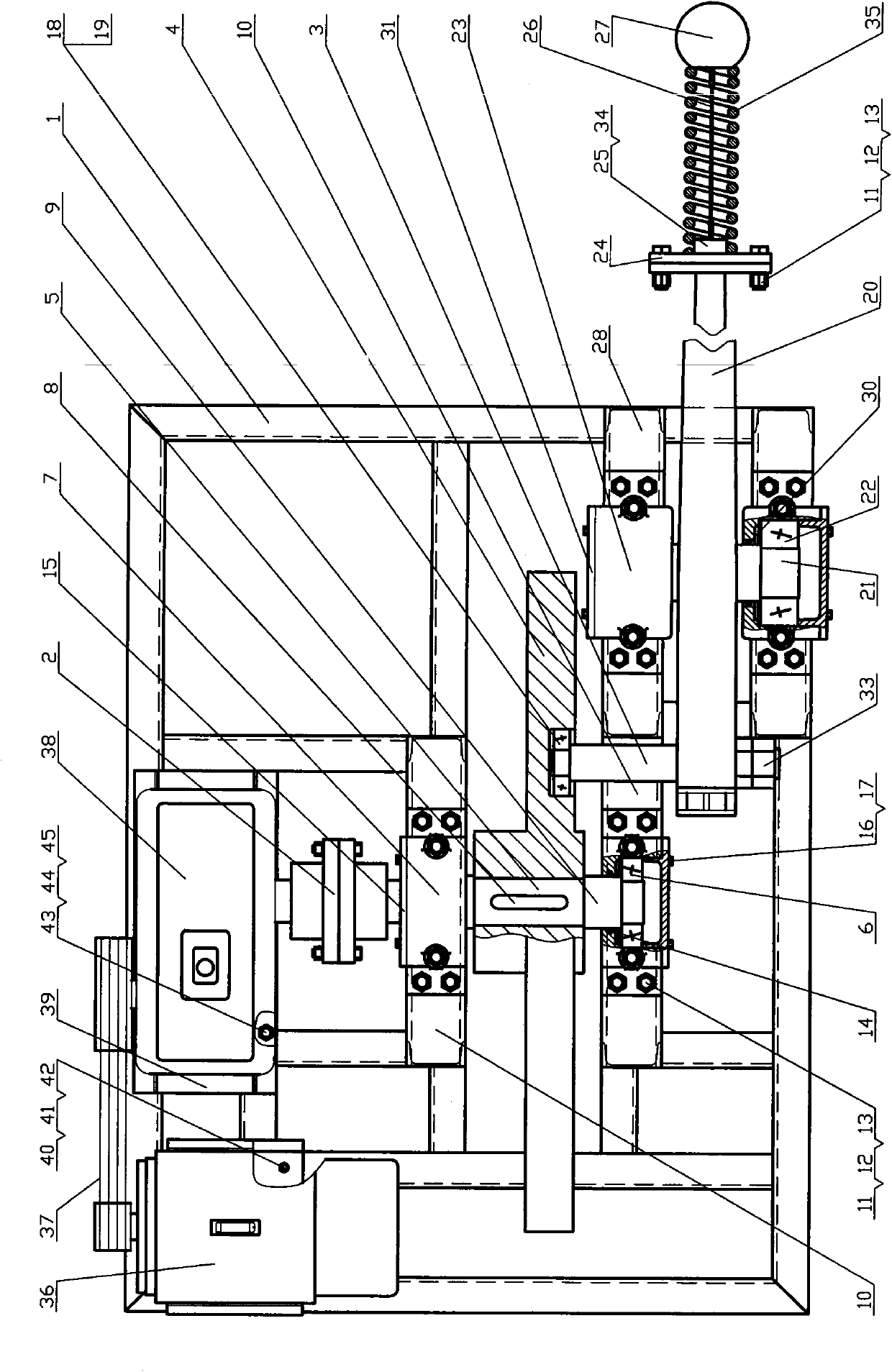

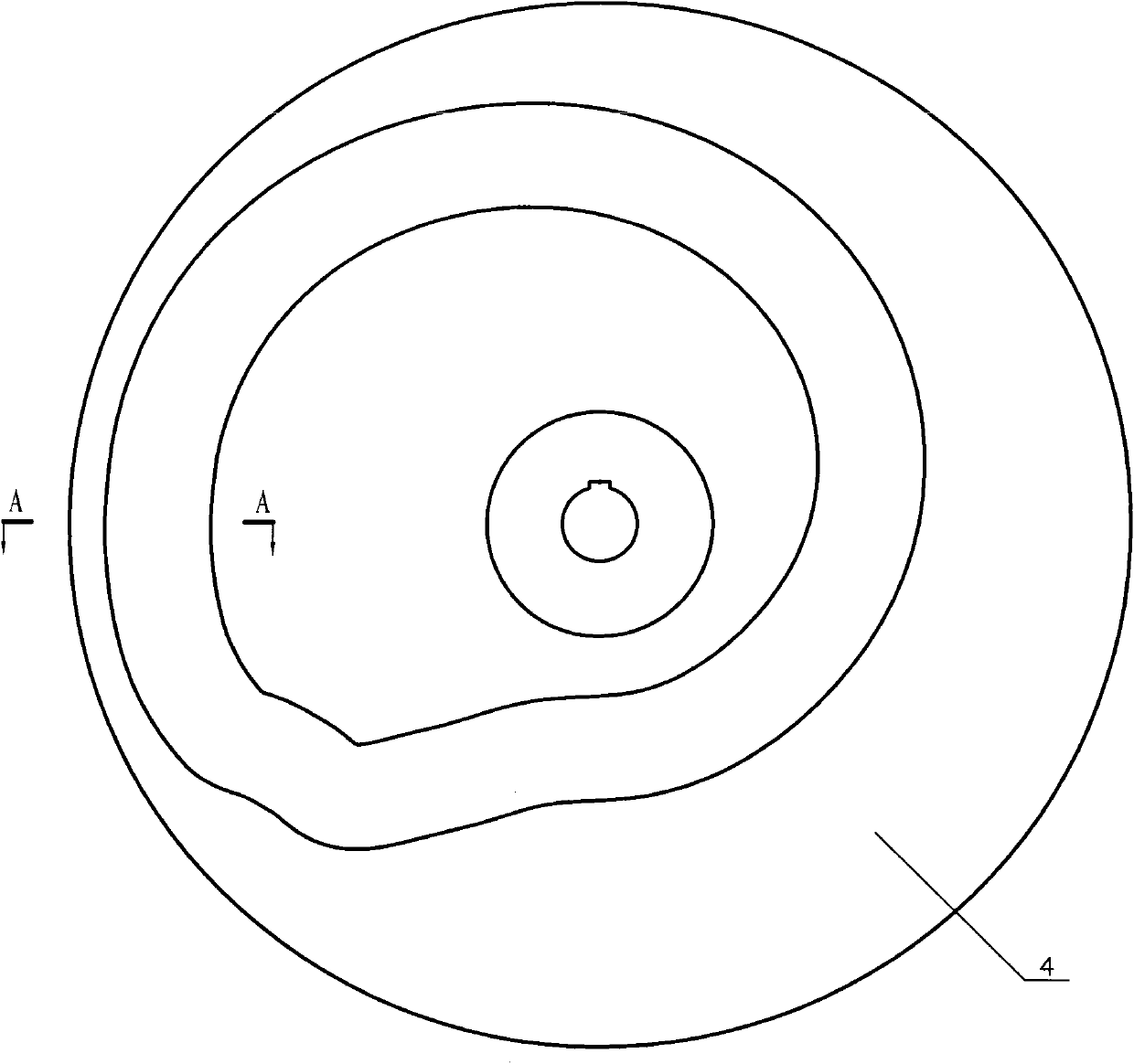

[0030] 1. Base 2, Coupling 3, Transmission Pin 4, Gear 5, Shaft I 6, Bearing I7, Bearing Block I 8, Key 9, Sleeve 10, Bracket I 11, Bolt I 12, Nut I13, Washer I 14, Sealing ring I 15, bearing cap I 16, bolt II 17, washer II 18, retaining ring 19, bearing III 20, lever 21, shaft II 22, bearing II 23, housing II 24, flange 25, joint 26, flexible Cable 27, impact hammer 28, bracket II 29, reinforcement plate I 30, sealing ring II 31, bearing cover II 32, reinforcement plate II 33, nut II 34, connecting ring 35, spring 36, motor 37, belt transmission mechanism 38, deceleration Machine 39, bracket III 40, bolt III 41, nut III 42, washer III 43, bolt IV 44, nut IV 45, washer IV 46, geared motor 47, self-positioning caster 48, supporting caster 49, material

[0031] exist Figure 1-8 and Figure 10In the shown embodiment: the bottom of the support III39 is fixed on the base 1, and the motor 36 fixed on the base 1 by the bolt III40, the nut III41 and the washer III42, after the spee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap