A nanocrystalline magnesium-aluminum-based hydrogen storage material and its preparation method

A hydrogen storage material and a magnesium-aluminum-based technology, which is applied in the field of nanocrystalline magnesium-aluminum-based hydrogen storage materials and preparation, can solve the problems such as the inability to meet the requirements of the energy storage density of the vehicle-mounted hydrogen storage system, poor mechanical properties, and difficulty in breaking. The ability to absorb and release hydrogen quickly, save production time, and reduce labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the magnesium-aluminum base hydrogen storage alloy of the present invention comprises the following steps:

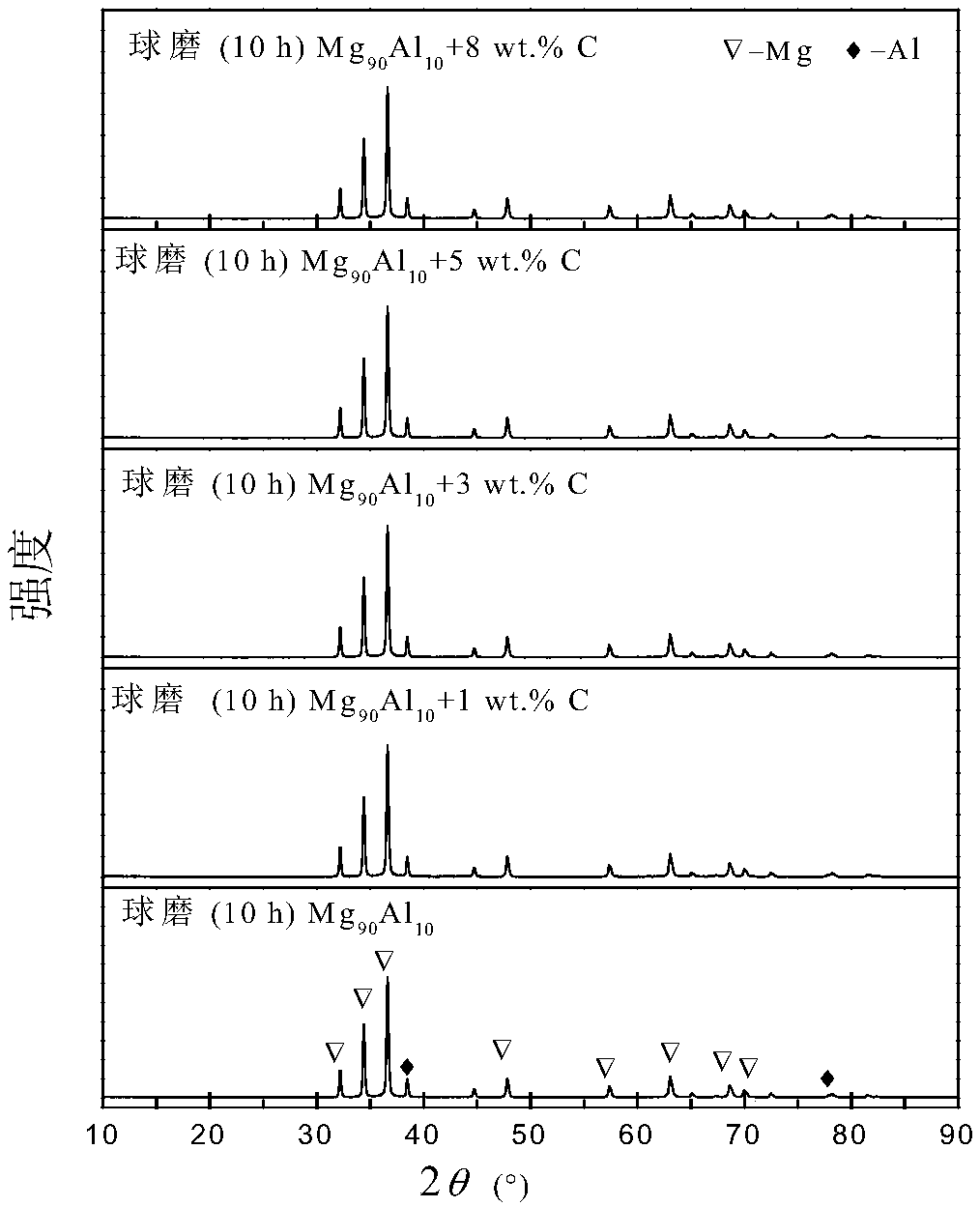

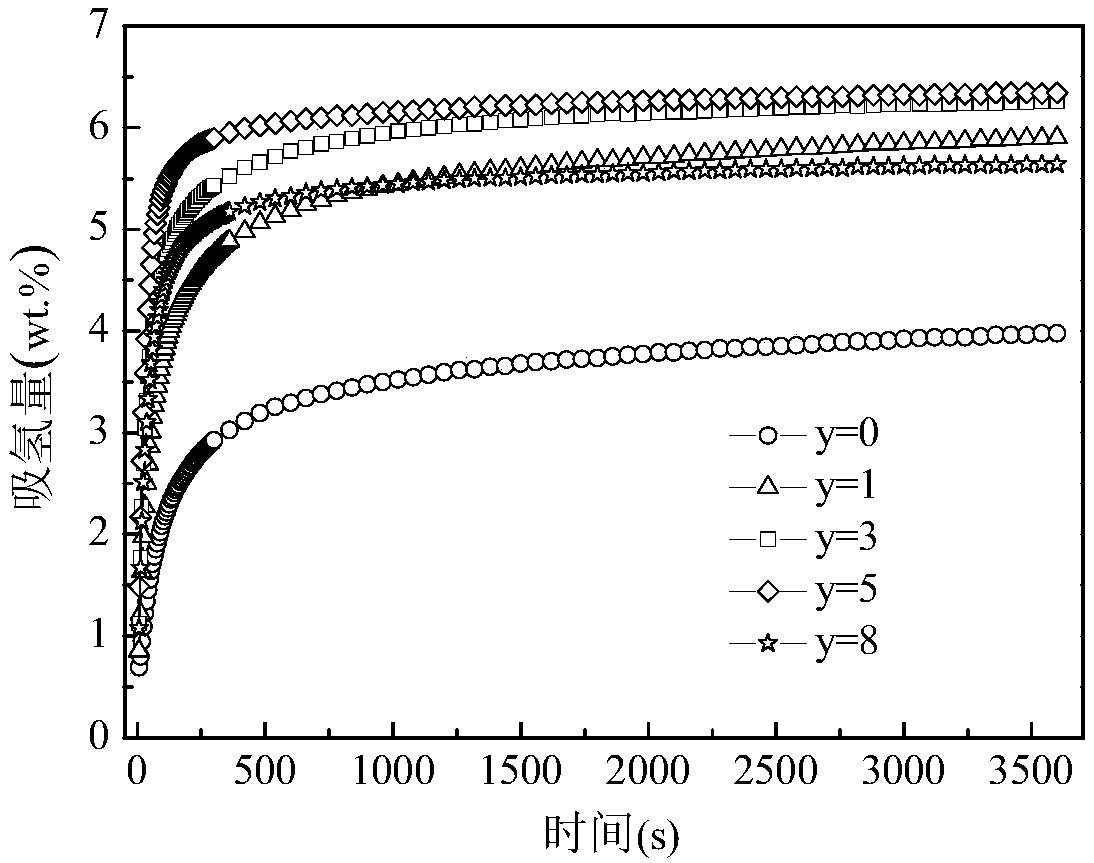

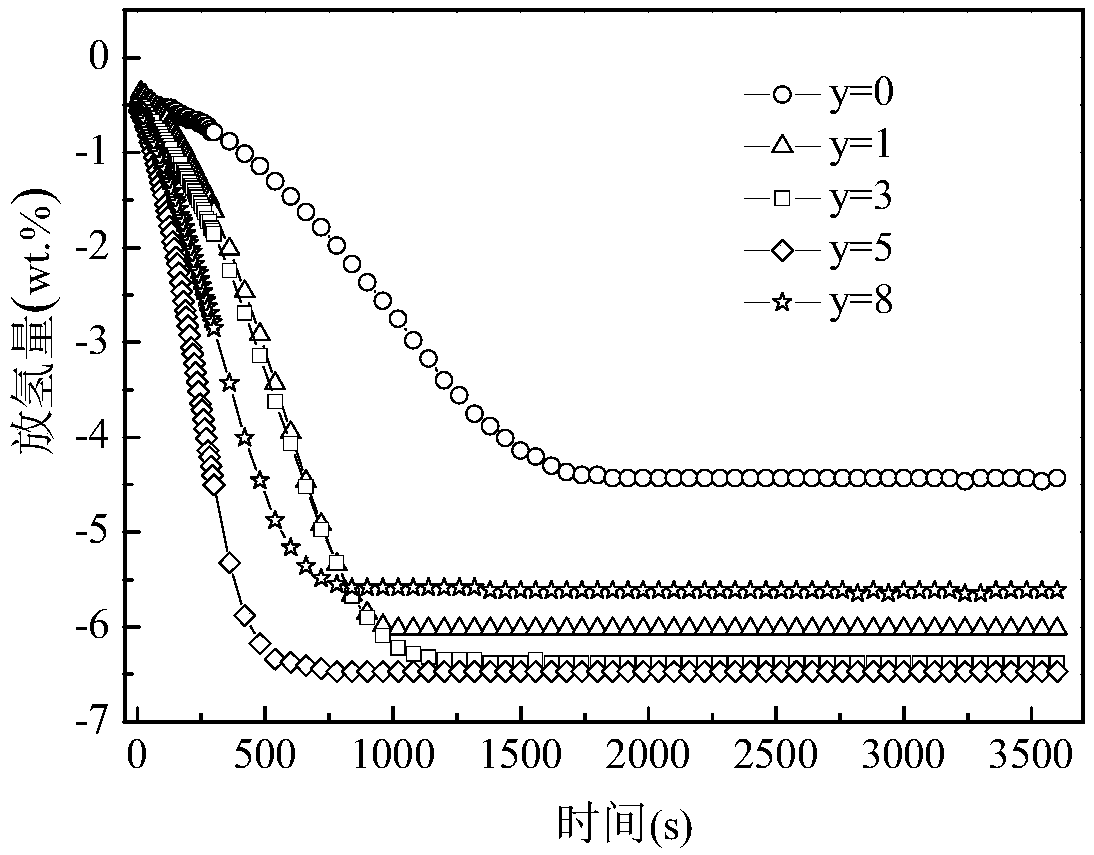

[0038] A. By chemical composition: Mg 100-x Al x +y(wt.%)C Weigh raw materials. In the formula, x is the atomic ratio, y is the mass percentage, and 10≤x≤30, 0≤y≤8. Choose 80-mesh magnesium grains and 200-mesh aluminum powder, and the purity of the metal used is >99%.

[0039]B. The magnesium particles and the aluminum powder are weighed and mixed according to the mass percentage, and the mixture is mixed with 1-8wt.% nano-graphite powder and put into a stainless steel ball mill jar. Add a certain mass ratio of stainless steel quenched grinding balls, the ball to material ratio is 20:1, and fill with high-purity argon as a protective gas. Set the rotating speed to 350r / min, start ball milling in the ball mill mode of 0.5h ball milling, rest 0.5h, and the total ball milling time is 10h. After ball milling, the powder was taken out an...

Embodiment 1

[0045] Example 1 Mg 90 Al 10

Embodiment 2

[0046] Example 2 Mg 90 Al 10 +1(wt.%)C

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com