Auger-free vibration grain receiving device

A technology of connecting rods and eccentric movement, which is applied in the agricultural field and can solve problems such as crushing of Sophora japonica and Sophora japonica

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

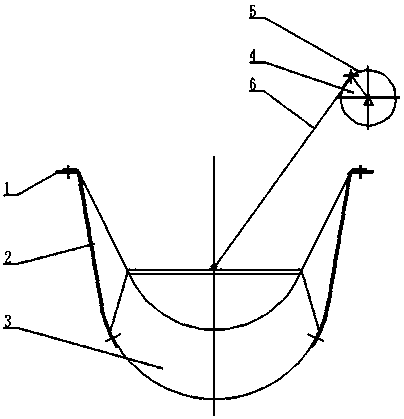

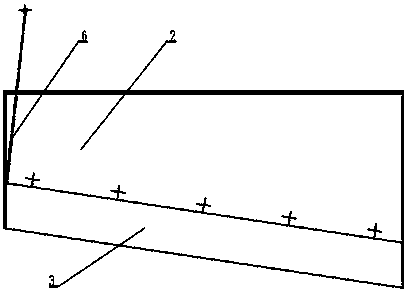

[0007] A vibrating grain receiving device without an auger, comprising a closed canvas, a grain receiving chute, and an eccentric movement mechanism; one end of the closed canvas 2 is fixed on the frame 1 by bolts, and the other end is fixed on the edge of the beam connecting chute 3; The grain receiving chute 3 is made of steel plate; Huai Mi enters from the top of the non-twisted beam connecting beam device and falls in the grain receiving trough 3; the eccentric movement mechanism is composed of an eccentric wheel 5 and a connecting rod 6, and one end of the connecting rod is used Bolts are fixed on the eccentric wheel 5 and the other end is fixed on the grain receiving chute 3 with bolts, and the eccentric movement mechanism is connected with the grain receiving trough, so that the sophora rice vibrates on the grain receiving trough and is transported to the outlet to complete the grain receiving operation; This process effectively solves the problem of crushing during thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com