Annular crusher for massive materials

A block material and crusher technology, which is applied in the field of mechanical equipment, can solve the problems that the axial swing of the hammer is not easy to control, and the impact point is not accurate enough, so as to improve the operation reliability and practicability, high impact efficiency, and reduce labor. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

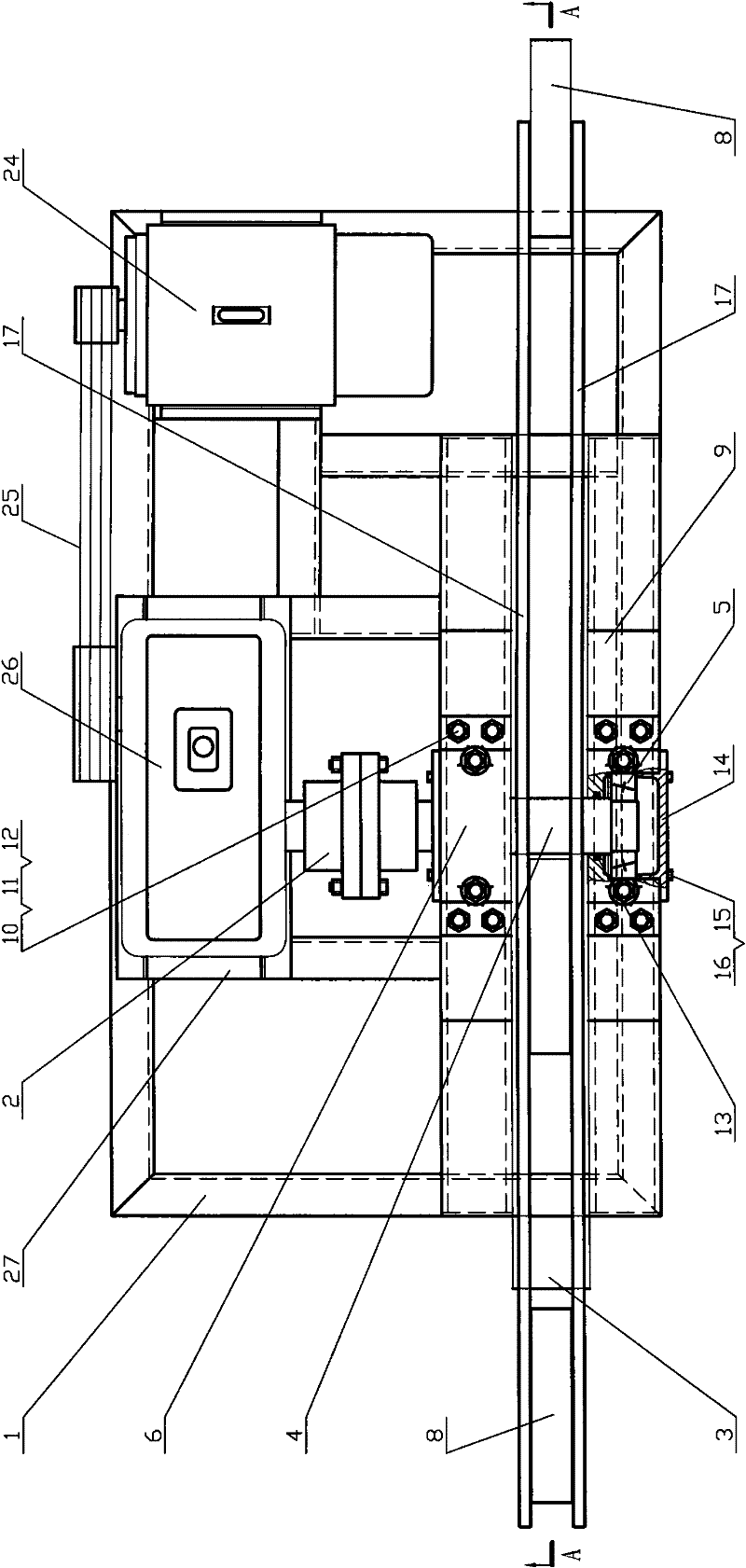

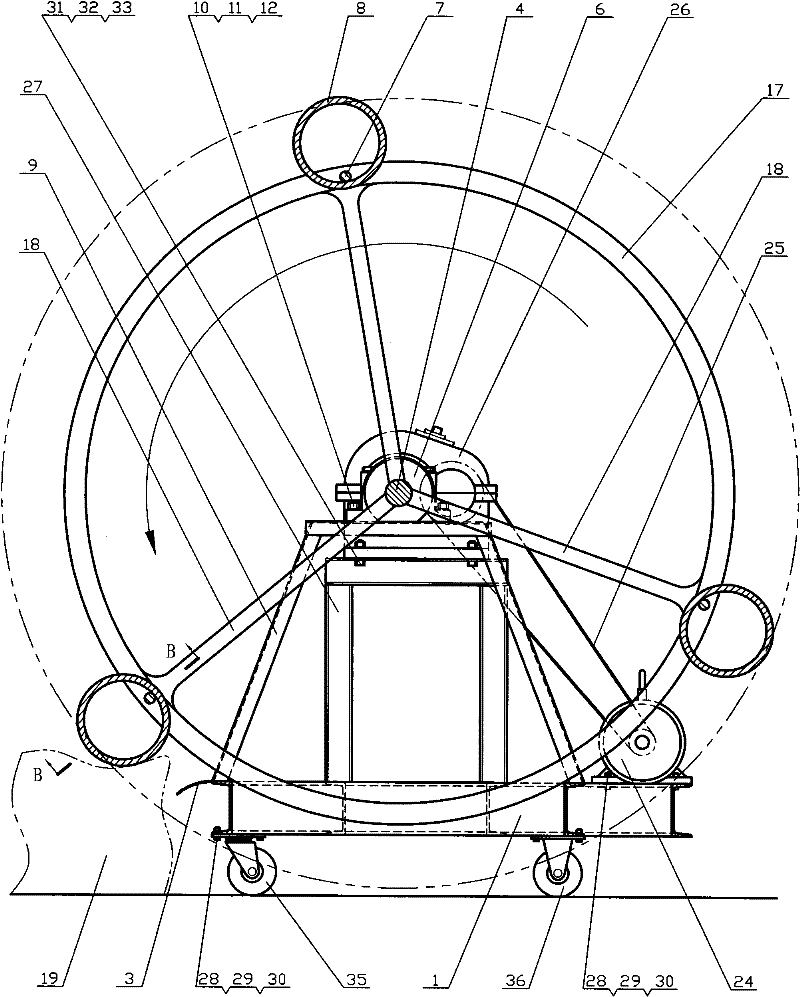

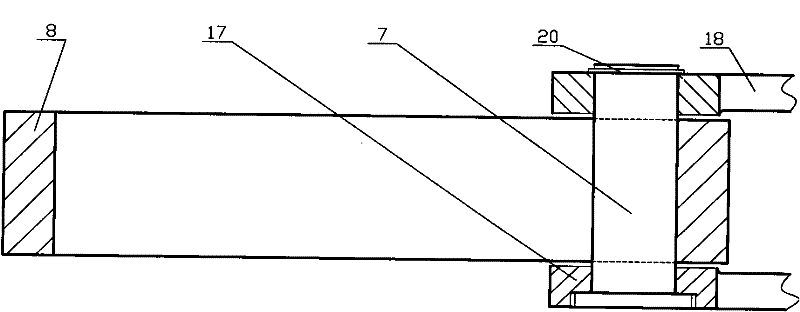

[0031] 1. Base 2, Coupling 3, Slideway 4, Shaft 5, Bearing 6, Bearing seat 7, Pin shaft 8, Hitting ring 9, Bracket I 10, Bolt I 11, Nut I 12, Washer I 13, Sealing ring 14. Bearing cover 15, bolt II 16, washer II 7, toggle frame 18, outrigger 19, material 20, retaining ring I 21, retaining ring II 22, nut III 23, washer III 24, motor 25, belt transmission mechanism 26. Reducer 27, bracket II 28, bolt IV 29, nut IV 30, washer IV 31, bolt V32, nut V 33, washer V 34, reduction motor 35, self-positioning caster 36, supporting caster

[0032] exist Figure 1 ~ Figure 3 , Figure 6 In the shown embodiment: the bottom of the bracket II27 is fixed on the base 1, and the motor 24 fixed on the base 1 by the bolt IV28, the nut IV29 and the washer IV30, after the belt transmission mechanism 25 is shifted, is connected with the bolt V31, the nut V32 It is connected with the input end of the speed reducer 26 fixed on the top of the support II27 with the washer V33. The bottom of the brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com