Method for processing negative crescent optical lens

An optical lens and processing method technology, applied in metal processing equipment, optical surface grinders, manufacturing tools, etc., can solve the problems of difficult to counterboring process parameters consistency, high cost of rigid disk preparation, affecting processing quality, etc. Reasonable and advanced processing methods, high production efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

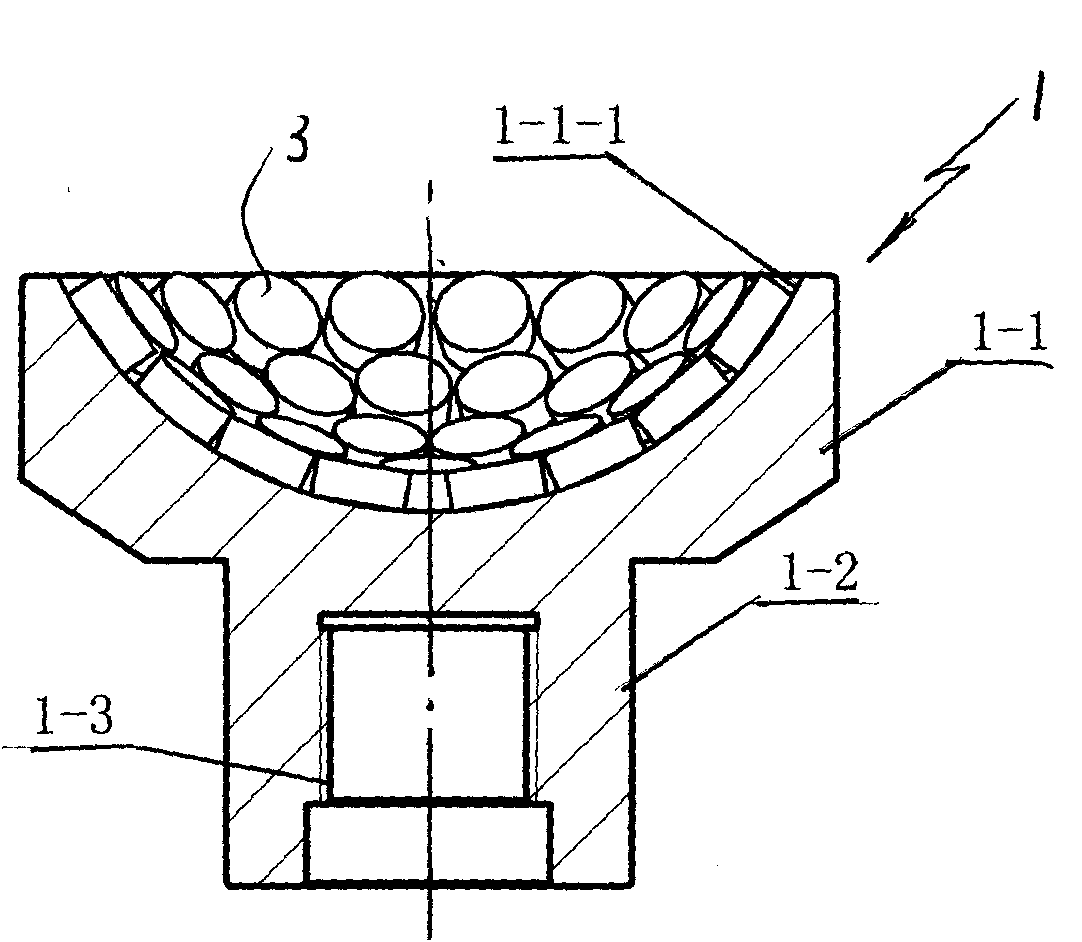

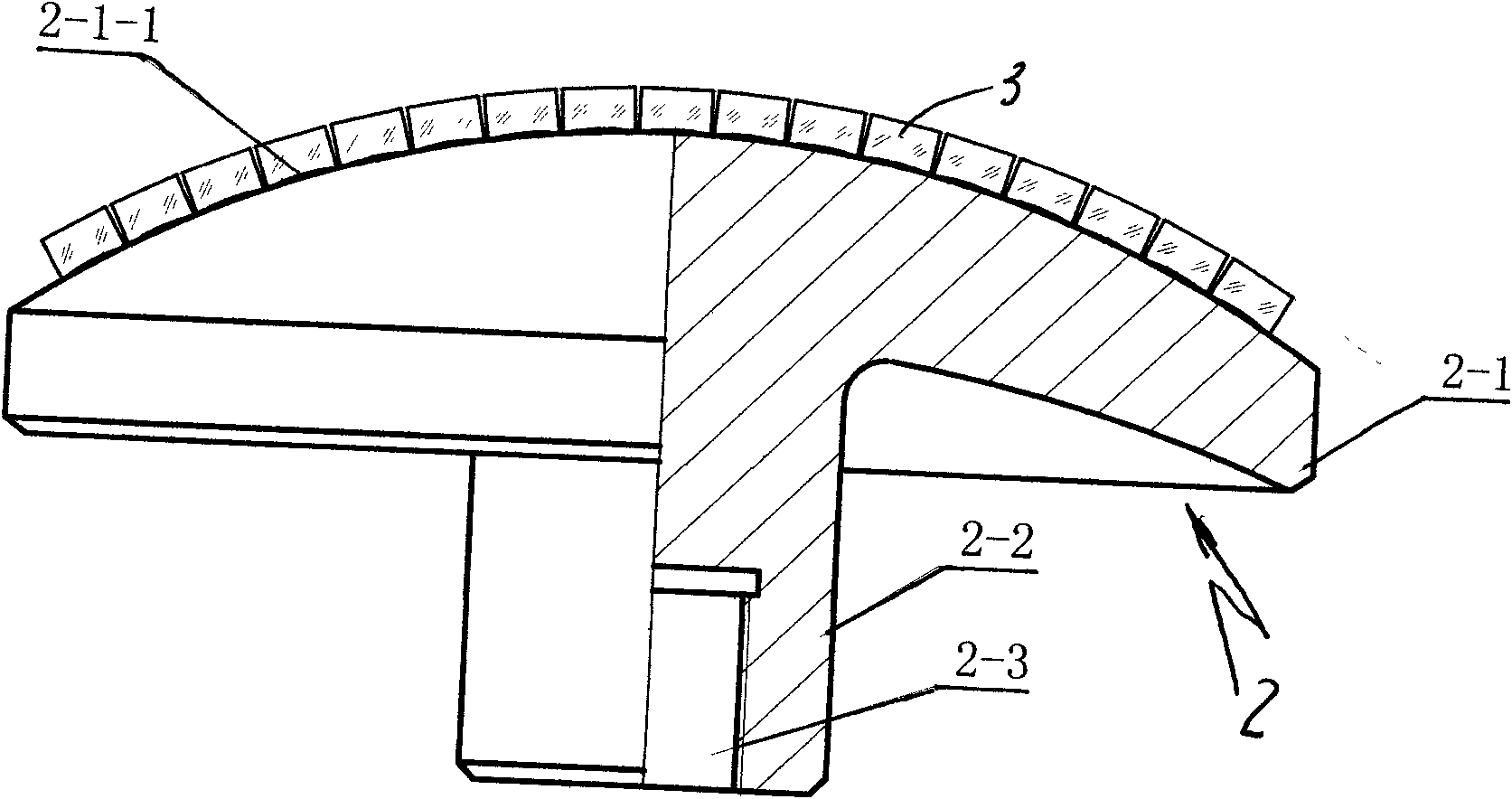

[0020] For a typical implementation, please refer to the attached Figure 1~3 .

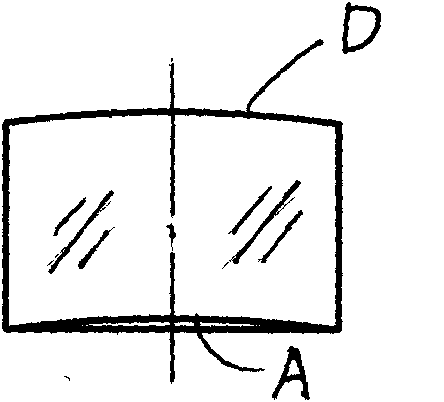

[0021] A negative crescent optical lens (as attached figure 1 The processing method shown in ) includes in turn: a. preparing a flat blank to be processed, and controlling the outer diameter of the flat blank to be within the range of process accuracy; b. placing the flat blank processed in step a in the concave On the spherical surface mold 1, process the spherical concave surface A of the flat blank; c, unload the processed workpiece with the spherical concave surface A processed through the b step from the concave spherical surface mold 1; d, unload the processed piece unloaded through the c step The piece is placed on the convex spherical mold 2, and the spherical convex surface D of the processed piece is processed, e, and the processed piece is unloaded from the convex spherical mold 2. And its:

[0022] Described concave spherical surface mold 1; It is to comprise the axle head 1-1 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com