Elevator sedan

A car frame and elevator technology, which is applied in the field of elevator car frames, can solve the problems of affecting the appearance of the car and wasting installation space, and achieves the effects of saving installation space, reducing requirements, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

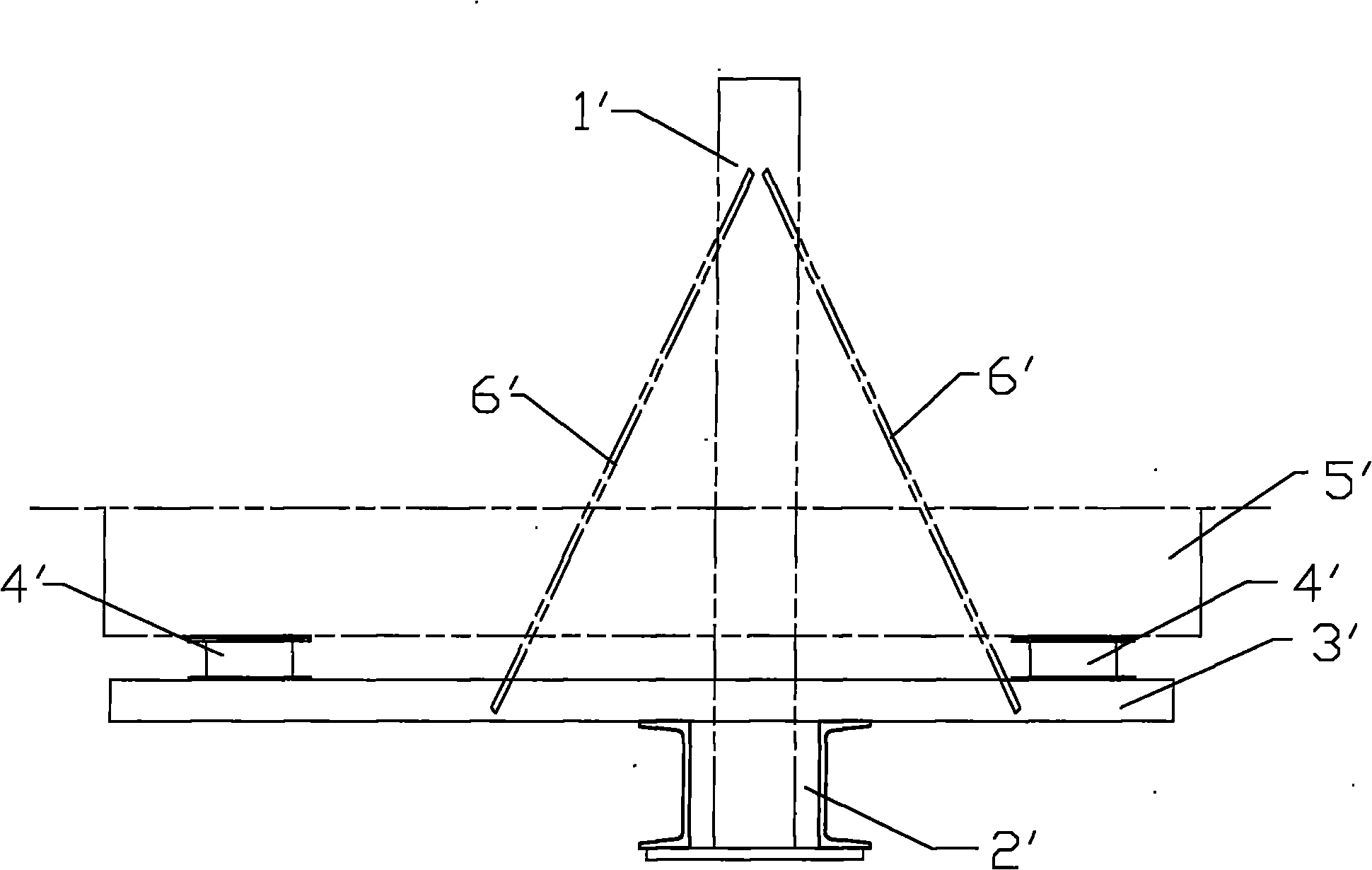

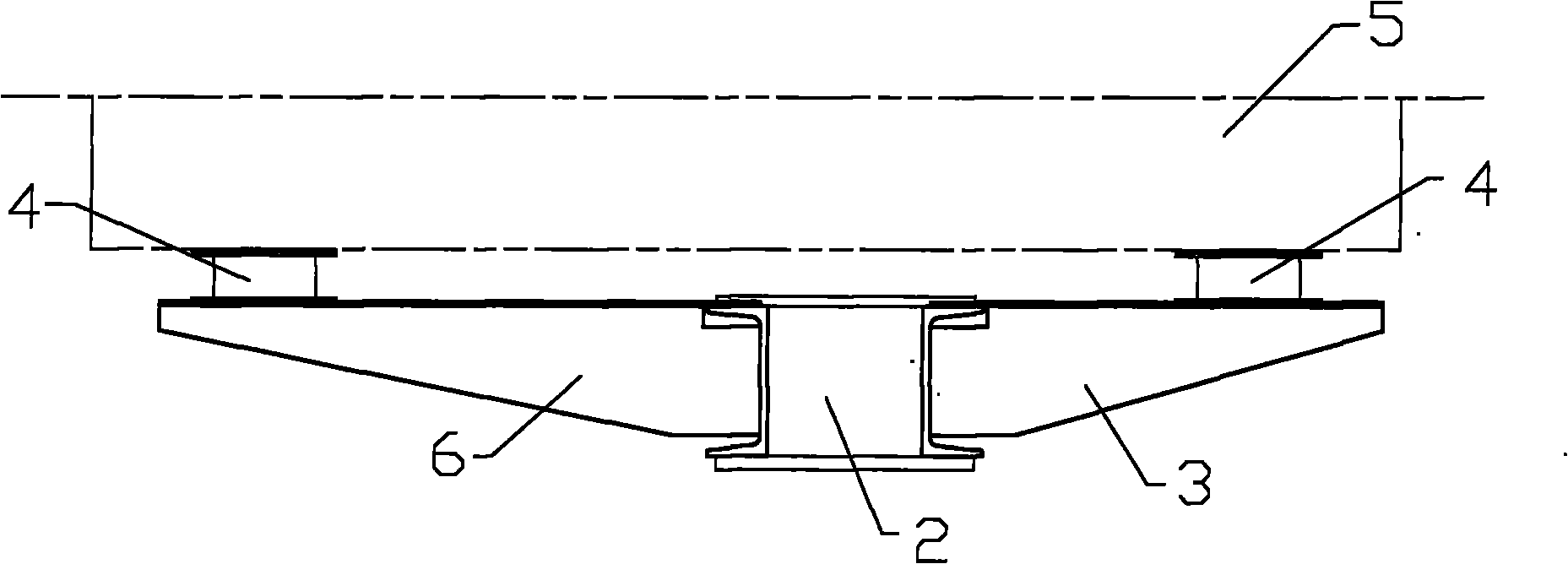

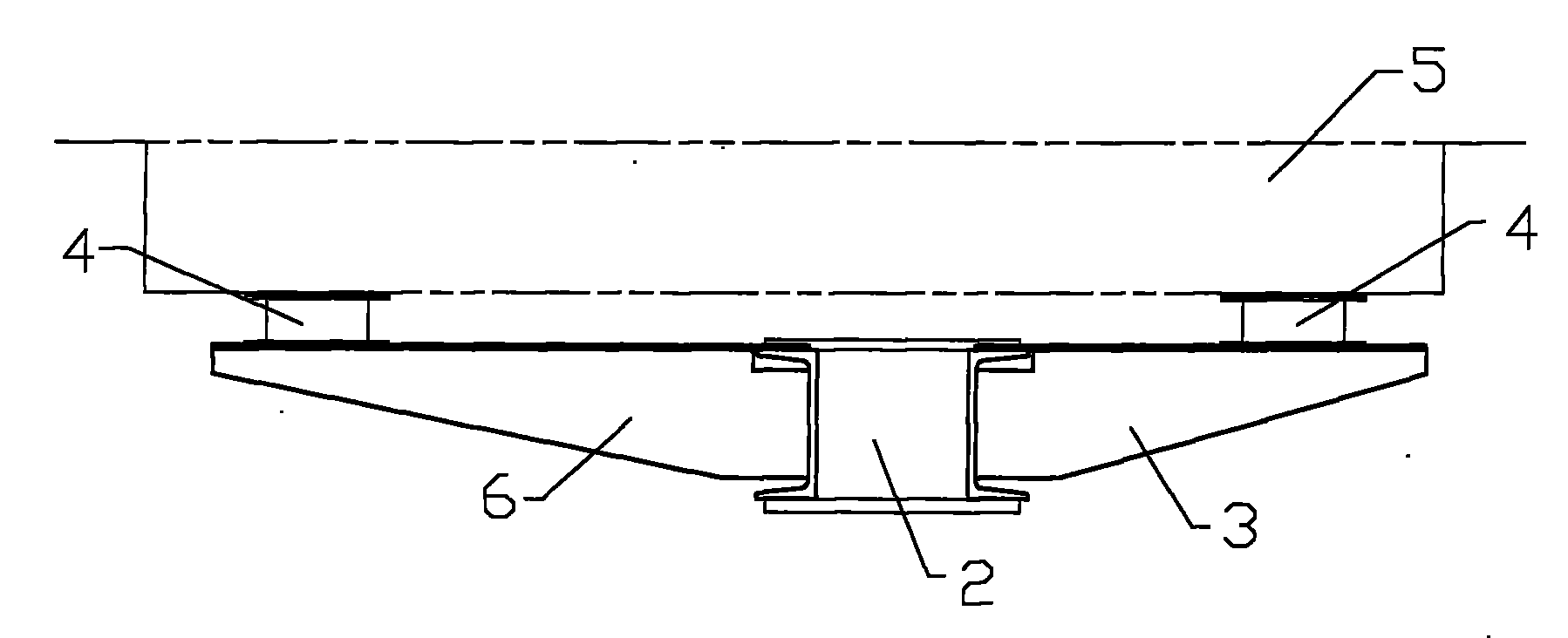

[0009] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0010] see figure 2 As shown, a kind of elevator car frame comprises two vertical beams, an upper beam and a lower beam connected between the two vertical beams, and the front and rear sides of the lower beam 2 are respectively fixed with a car front support 3 and a car rear support 6. The car front support 3 and the car rear support 6 are arranged between the planes where the upper and lower surfaces of the lower beam 2 are located, that is to say, the upper surfaces of the car front support 3 and the car rear support 6 are not high On the upper surface of the lower beam 2, the lower surface of the car front support 3 and the car rear support 6 is not lower than the lower surface of the lower beam 2, and the car front support 3 and the car rear support 6 are all provided with There is a shock-absorbing element 4, and the shock-absorbing element 4 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com