Auxiliary pipe-conveying device for on-site mixed explosive

A technology of mixing explosives and delivering tubes on site, which is applied to ammunition, ammunition storage, weapon accessories, etc., can solve the problems of large wear of drug delivery tubes, high labor intensity of workers, and high production costs, and achieve the solution of charging problems and improve Charge structure, effect of improving charge accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1. In this embodiment, electric power is selected to work as the power source 6 of the lead screw. The power source 6 of the lead screw adopts an explosion-proof variable frequency motor, the clamping part adopts an electromagnetic device, and the power source 14 of the clamping adopts an electromagnet;

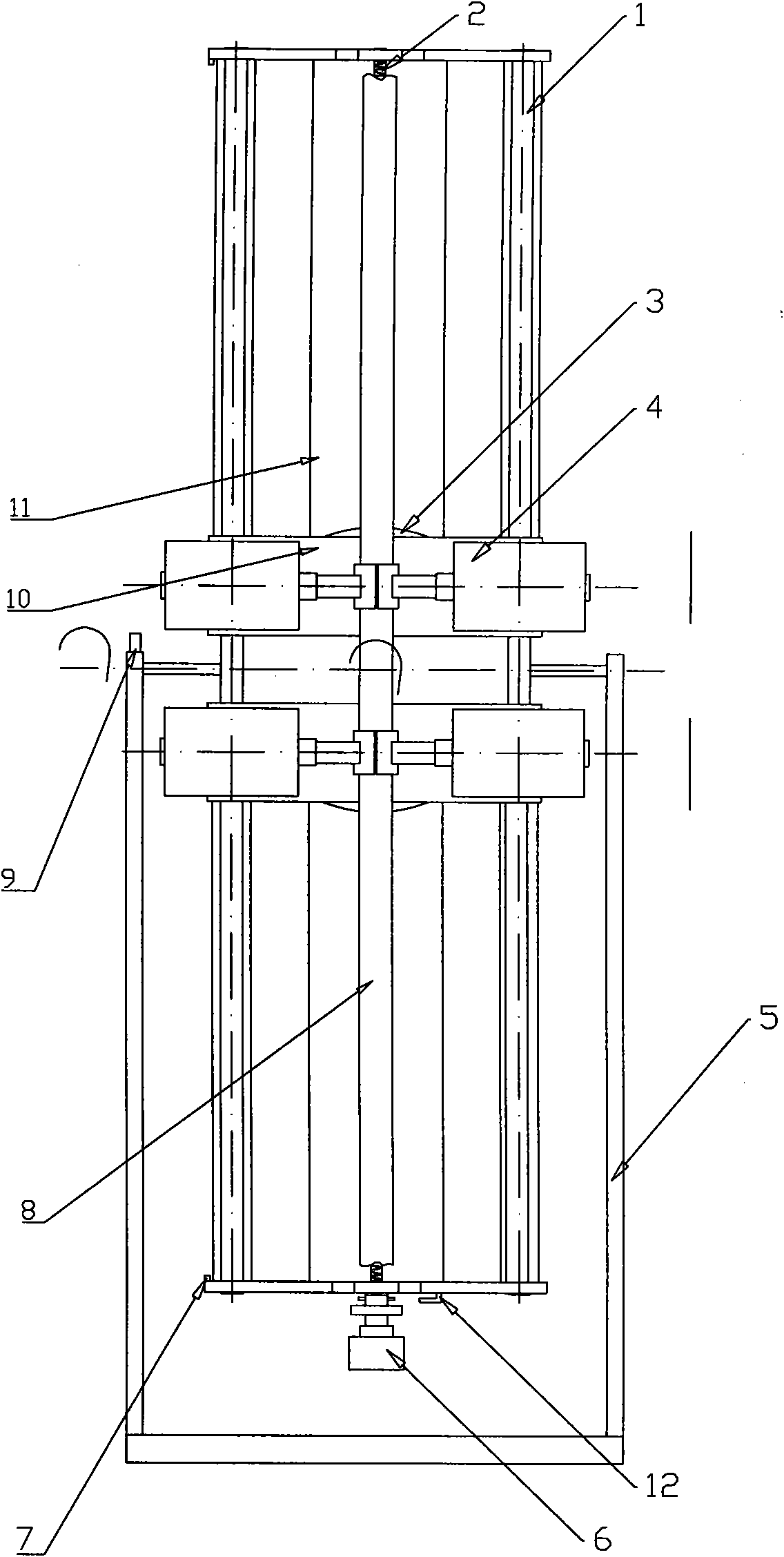

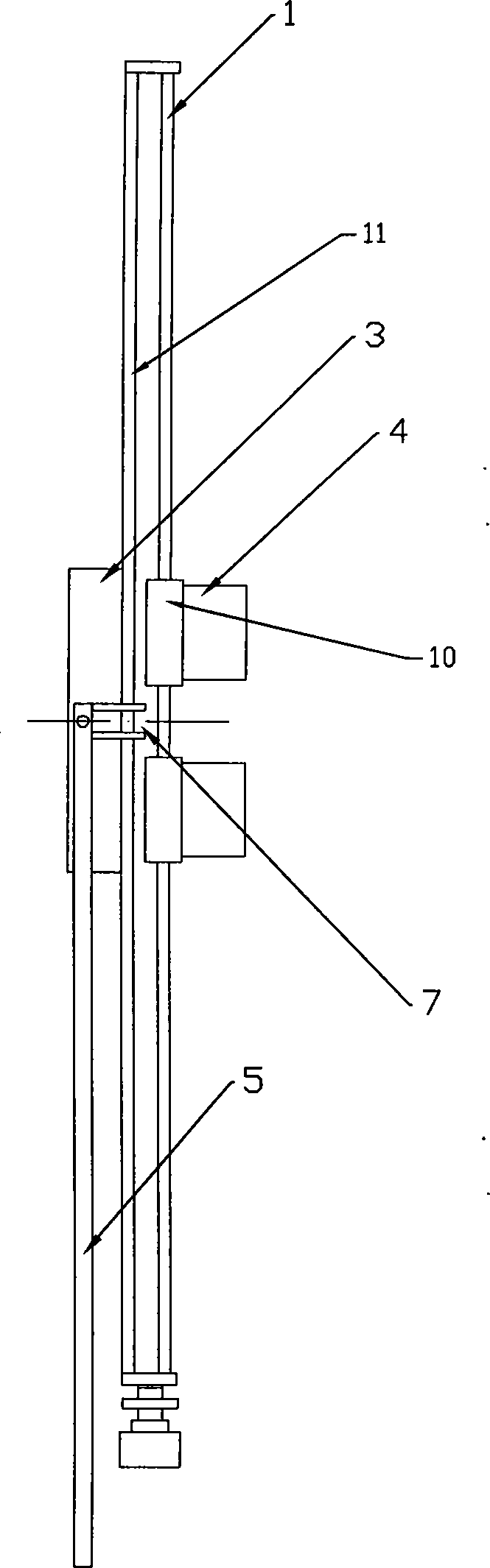

[0026] The whole device consists of three parts: a bracket part, a guide rail part and a clamping part.

[0027] The support part includes a support 5, a turret 3 and a lock 9; the support 5 is a support base of a fixed truss structure, the turret 3 is a rotatable disk frame composed of two rotating shafts, and the turret 3 passes through the bearing Connected with the bracket 5, the main function is to support the rotation of the whole device and the guide rail, and the locking device 9 is installed on one side of the bracket.

[0028] The guide rail part includes a guide rail seat 11, a reciprocating lead screw 2, a guide post 1, a power source 6 for the l...

Embodiment 2

[0033] Embodiment 2. In this embodiment, when hydraulic pressure is used as the power source of the screw, the power source of the screw is a hydraulic motor, the clamping part is a hydraulic device, and the power source of the clamping is a hydraulic cylinder.

[0034] This embodiment except clamper, other structures are identical with embodiment 1;

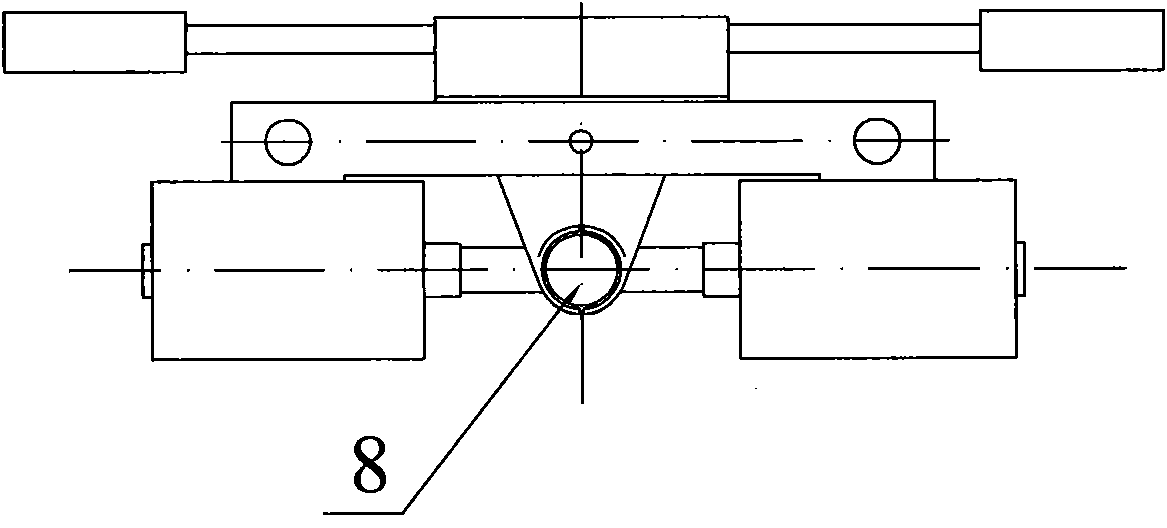

[0035] The clamper includes a base 13, a hydraulic cylinder, a spring 15, a clamping block 16, a clamping head 17 and a spacer 18, wherein the clamping block 16 is a pair of polygonal structures symmetrical to the drug delivery tube 8, A pair of clamping blocks 16 are sleeved on the base 13 through the pins, and the spring 15 is arranged on the pins, connected with the base 13 and the clamping block 16, and plays the role of pre-tightening and reset, and the two ends of the hydraulic cylinder are clamped by the pins The block 16 is connected, and the clamp head 17 is lined with a block 18;

[0036] The material of the pad 18 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com