T-max plant stem flow measuring method and device thereof

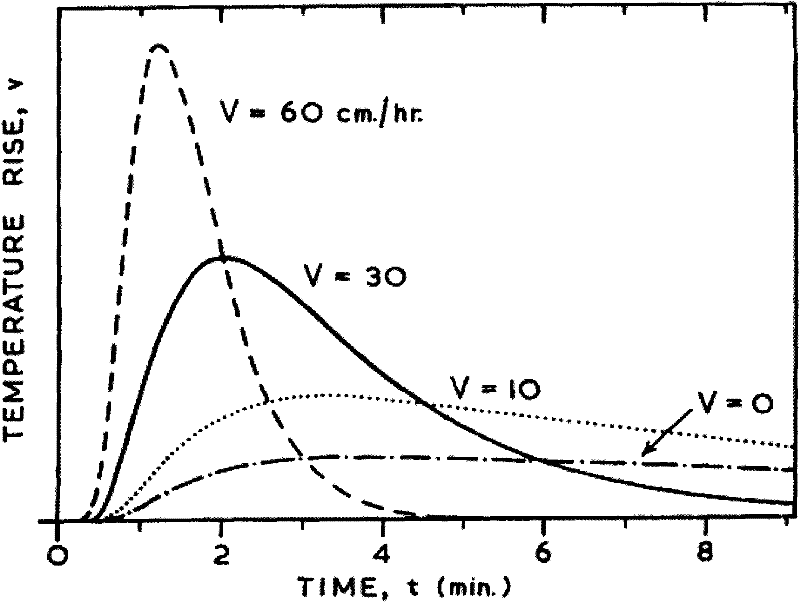

A measurement method and plant stem technology, applied in the field of T-max plant stem flow measurement and its device, can solve the problems of low heating accuracy, poor ability to measure low-speed stem flow, high cost, etc. The effect of strong interference ability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

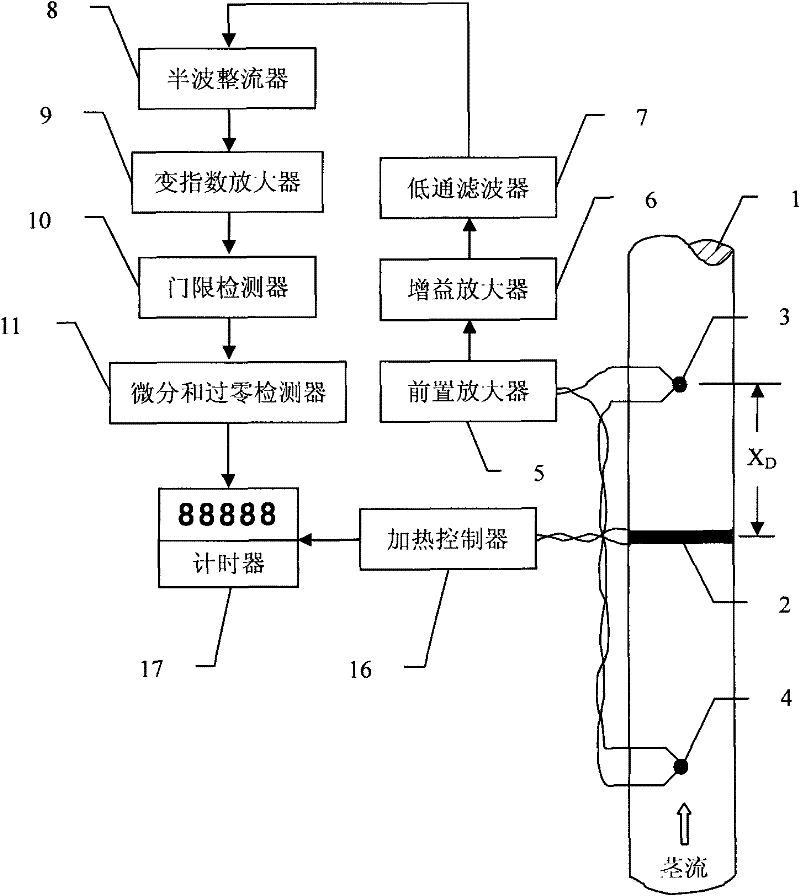

[0095] Example: such as Figure 4 As shown, the temperature difference is composed of the detection temperature sensor 3 installed on the plant stem 1 at a distance of 15 mm from the heater 2 downstream of the stem flow and the compensation temperature sensor 4 installed at a distance of 40 mm from the heater 2 upstream of the stem flow Detector, temperature sensor adopts T-type thermocouple. Figure 5 , 6 , 7, 8 are circuit diagrams of embodiments of the present invention, and Figure 4 The corresponding relationship is as follows: the output terminal of the temperature difference detector and Figure 5 Composed of integrated circuits U1, U2, capacitors C1, C2, C3, C8, resistors R1, R2, R3, R4, R5, R6, R7, R8, R9 Figure 4 The preamplifier 5 is connected to each other, and the resistors R1, R2, R3, R4, R7, R8, capacitors C1, C2, C3, and C8 form a passive low-pass filter for suppressing out-of-band high-frequency noise. The output of the preamplifier 5 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com