Method and device for analyzing Squeak and Rattle noise

A noise and source technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve the problems of wasting materials, cumbersome and time-consuming processes, and achieve the effect of avoiding wasting materials and reducing the time required.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

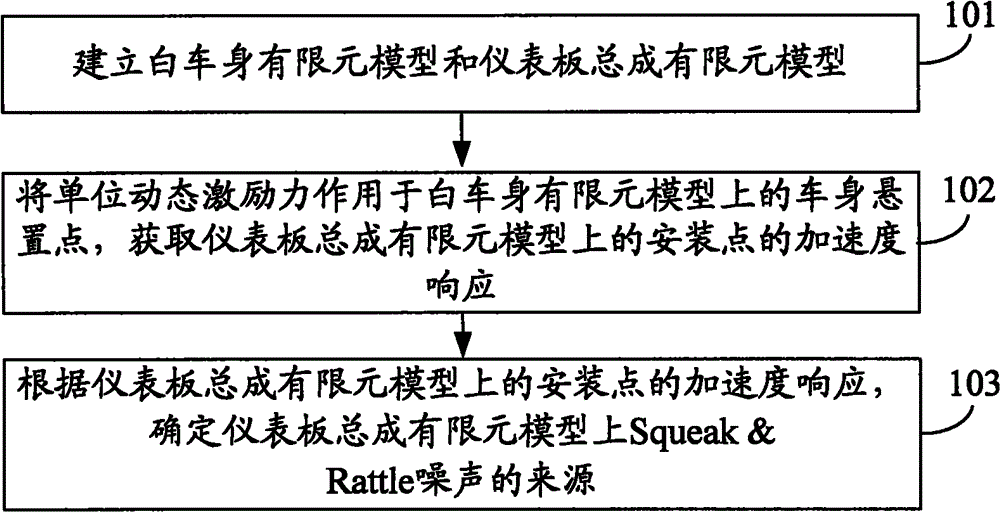

[0025] see figure 1 , the embodiment of the present invention provides a method for obtaining the source of Squeak & Rattle noise, including:

[0026] 101: Establish the finite element model of the body in white and the finite element model of the instrument panel assembly.

[0027] 102: Apply the unit dynamic excitation force to the suspension point of the vehicle body on the finite element model of the body-in-white, and obtain the acceleration response of the installation point on the finite element model of the instrument panel assembly.

[0028] 103: According to the acceleration response of the installation point on the finite element model of the instrument panel assembly, determine the source of the Squeak & Rattle noise on the finite element model of the instrument panel assembly.

[0029] Further, when establishing the finite element model of the body-in-white and the finite element model of the instrument panel assembly, it also includes: establishing the steering ...

Embodiment 2

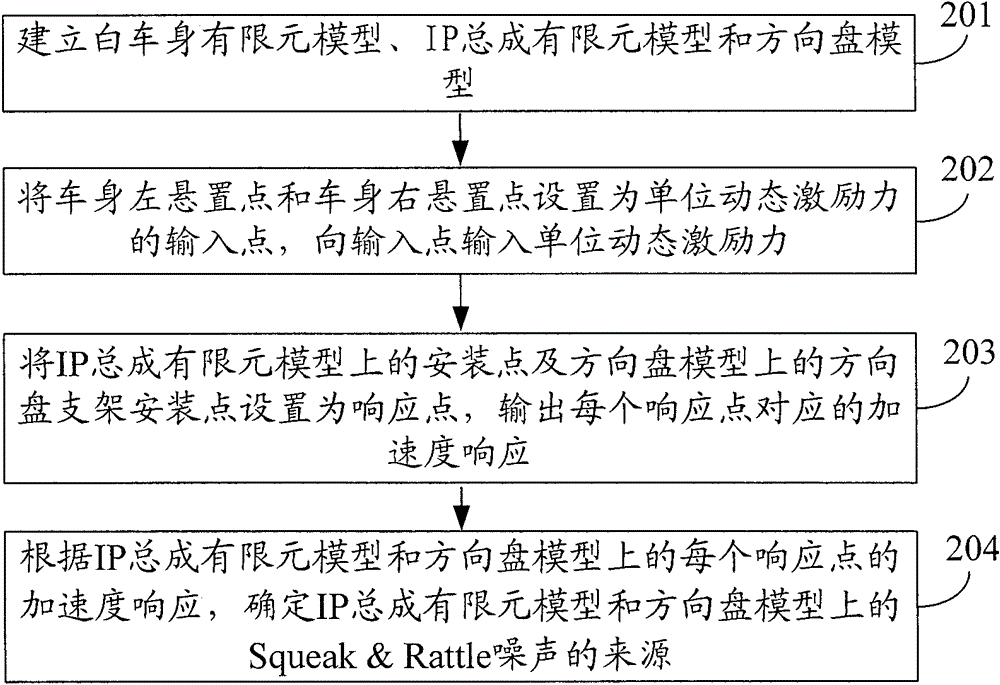

[0035] The embodiment of the present invention finds through a large amount of test results that the Squeak & Rattle noise that the automobile produces is mainly related to the vibration acceleration of the installation point on the IP (Instrument Panel, instrument panel assembly) assembly. Under certain excitation, if the IP assembly If the mounting point has a high vibration acceleration, the mounting point will easily become loose after a period of time, thereby generating Squeak & Rattle noise. According to the above principles, the embodiment of the present invention provides a method for obtaining Squeak & Rattle noise source method, see figure 2 , the method includes:

[0036] 201: Establish the finite element model of the body in white, the finite element model of the IP assembly and the steering wheel model.

[0037] Among them, the IP assembly finite element model is mainly the skeleton model of the instrument panel. And it should be noted that, in order to be mor...

Embodiment 3

[0050] see image 3 , the embodiment of the present invention provides a kind of device that obtains Squeak & Rattle noise source, and this device comprises:

[0051] The model building module 301 is used for building the finite element model of the body-in-white and the finite element model of the instrument panel assembly.

[0052] The acceleration response acquisition module 302 is used to apply the unit dynamic excitation force to the vehicle body suspension points on the body-in-white finite element model after the model building module 301 establishes the finite element model of the body-in-white and the finite element model of the instrument panel assembly to obtain the instrument Acceleration response of mounting points on a plate assembly finite element model.

[0053] Squeak & Rattle noise source acquisition module 303, for obtaining the acceleration response of the installation point on the instrument panel assembly finite element model after the acceleration respo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap