A Digital Differential Pressure Rod Position Measuring Device

A measuring device and differential pressure technology, applied in the fields of nuclear reactor monitoring, reactor, nuclear power generation, etc., can solve the problems of high production requirements, increased coil failure probability, slow response speed, etc., to improve safety and reliability, avoid electromagnetic Coupling problems, effect of reduced installation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

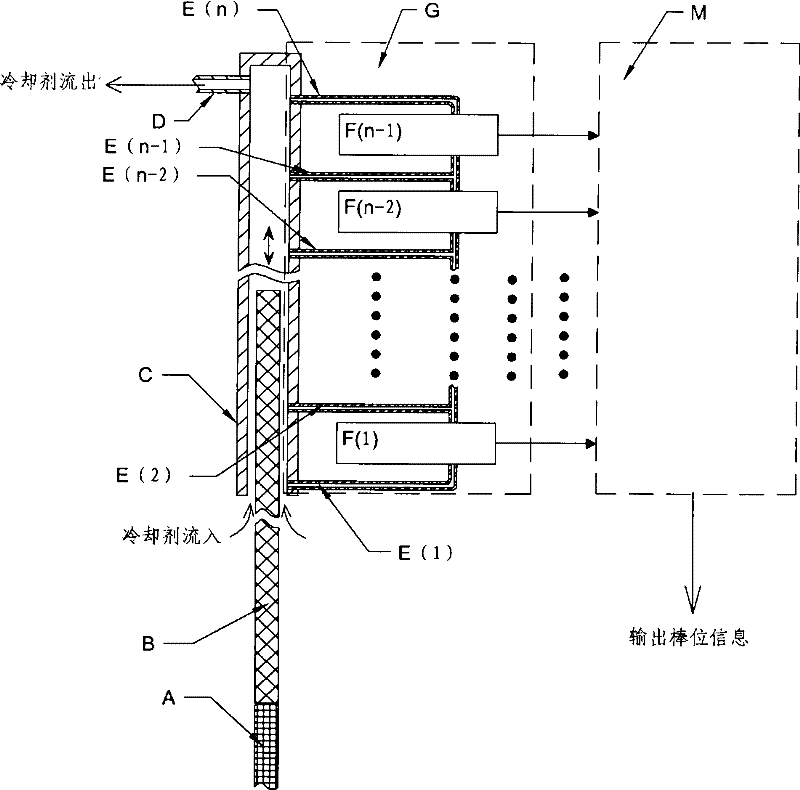

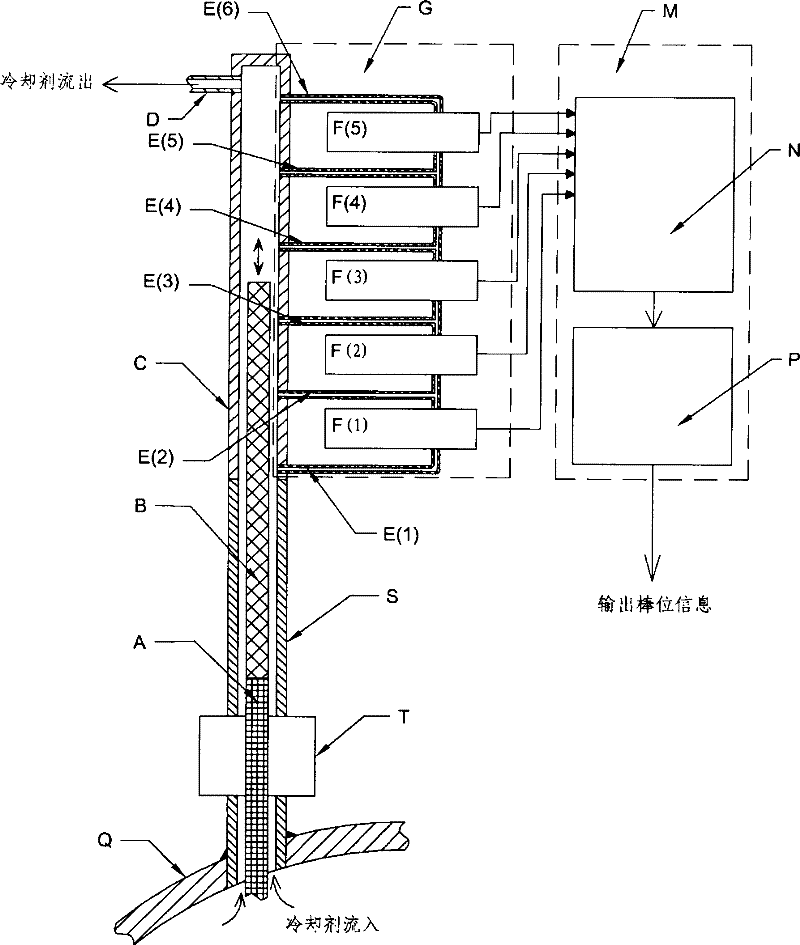

[0026] Through proper principle and structural design, the present invention adopts common industrial transmitters as signal acquisition equipment, and the number of acquisition units is greatly reduced. It has the characteristics of mature manufacturing process, convenient installation, simple structure, convenient maintenance and high reliability. The invention provides a digital differential pressure rod position measuring device comprising:

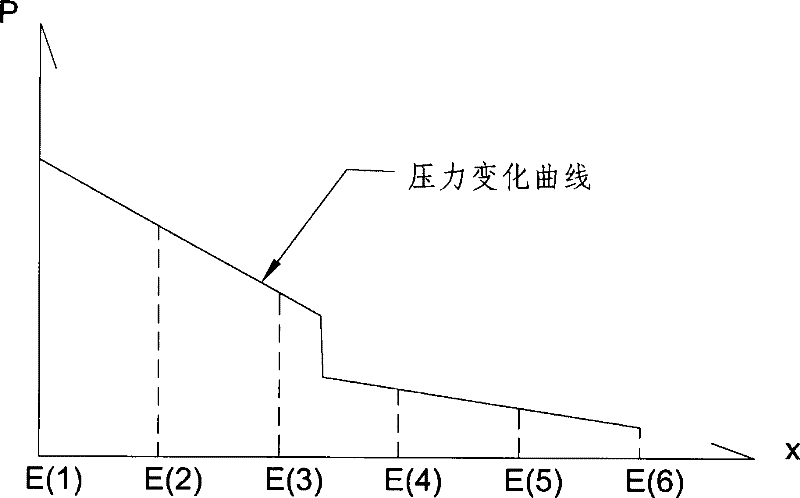

[0027] A differential pressure reference pipe, its inlet end and the outlet drain pipe connected to the side wall of the outlet end communicate with the coolant fluid part in the reactor system respectively. The fluid pressure of the part connected to the inlet port is higher than the fluid pressure of the part connected to the port of the outlet drainage tube;

[0028] On the other side wall of the differential pressure reference tube, a number of pressure induction tubes for differential pressure measurement and a set of correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com