Track rail and motion guide device with the track rail

A motion guidance and guide rail technology, applied in the direction of linear motion bearings, mechanical equipment, bearings, etc., can solve the problem of not being able to ensure the load contact surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, preferred embodiments for carrying out the present invention will be described using the drawings. In addition, the following embodiments do not limit the technical means related to each claim, and also do not limit that all combinations of the features described in the embodiments are essential to the solution means of the invention.

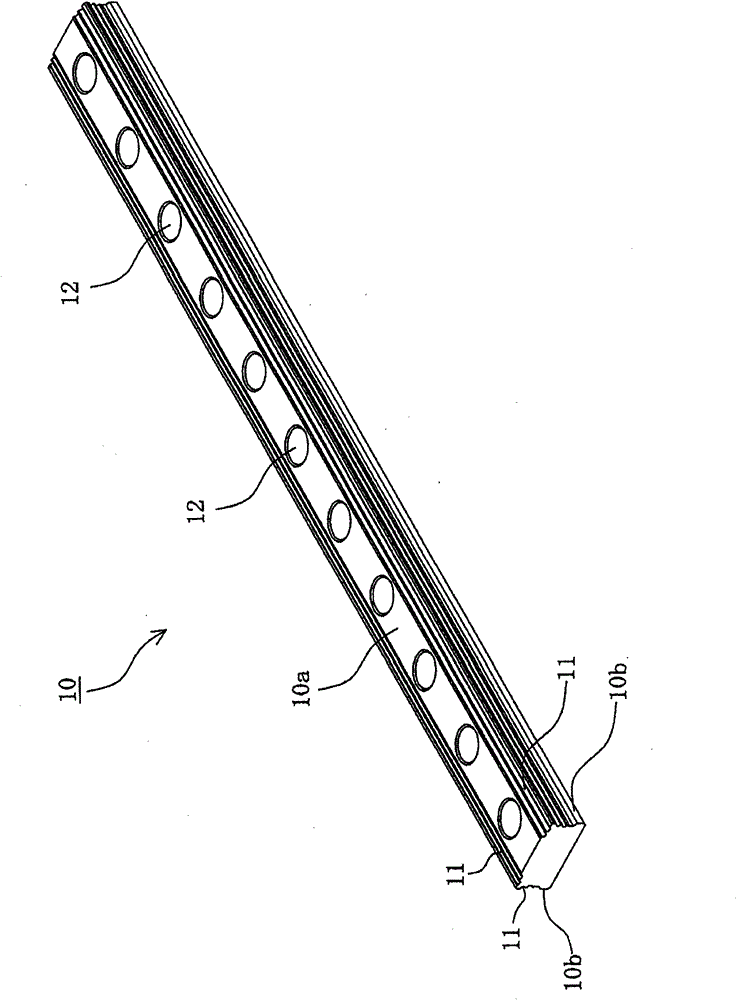

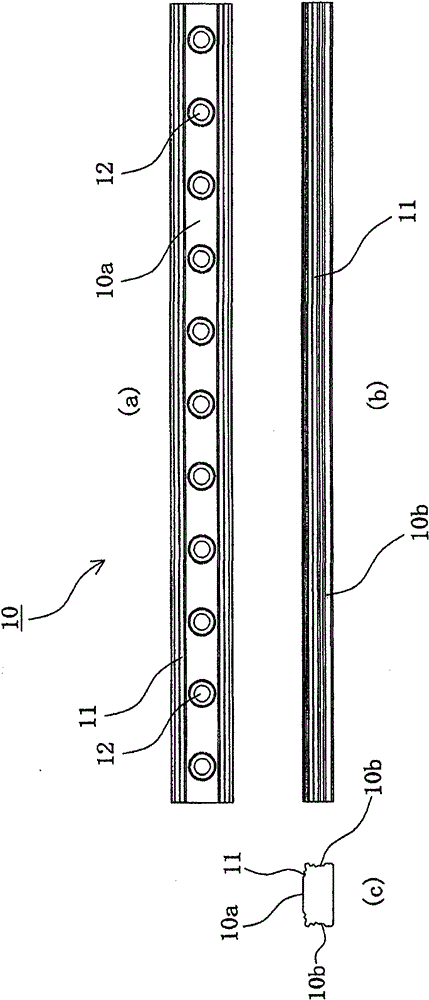

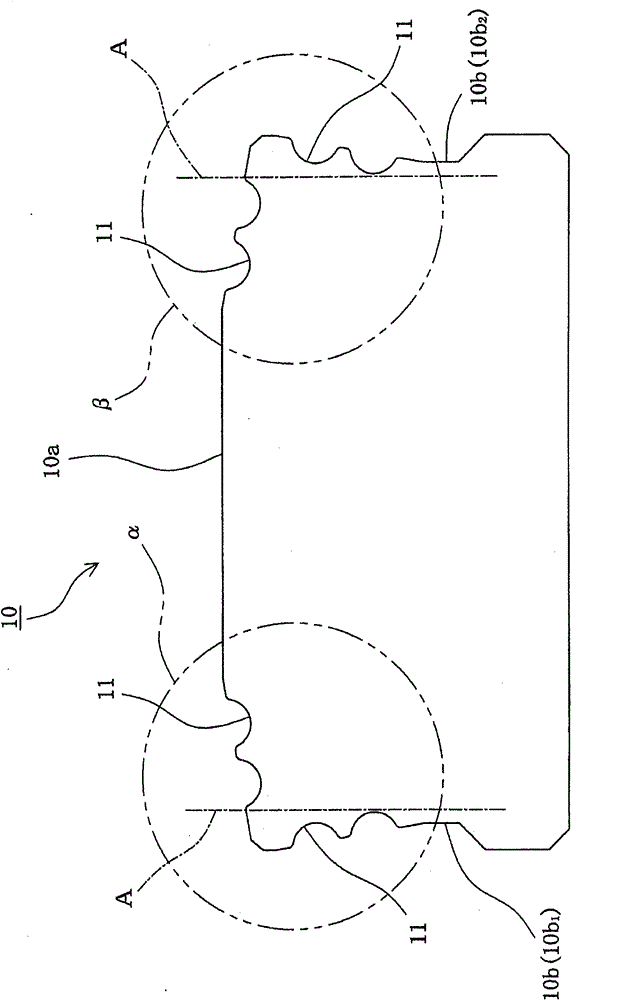

[0028] figure 1 It is an external perspective view of the guide rail according to this embodiment. and, figure 2 It is a figure for explaining the guide rail concerning this embodiment, figure 2 (a) is a top view, figure 2 (b) is a side view, figure 2 (c) Main view. in addition, image 3 It is a drawing which shows the characteristic front shape in the guide rail which concerns on this embodiment.

[0029] exist Figure 1 to Figure 3 The guide rail 10 according to the present embodiment shown in FIG. A plurality of unillustrated balls installed in a state of being assembled with an unillustrated moving block can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com