Check valve for small size hot-water boiler for preventing noise

A hot water boiler, noise-free technology, applied in valve details, control valves, safety valves, etc., can solve problems such as excessive noise and frequent activation of check valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

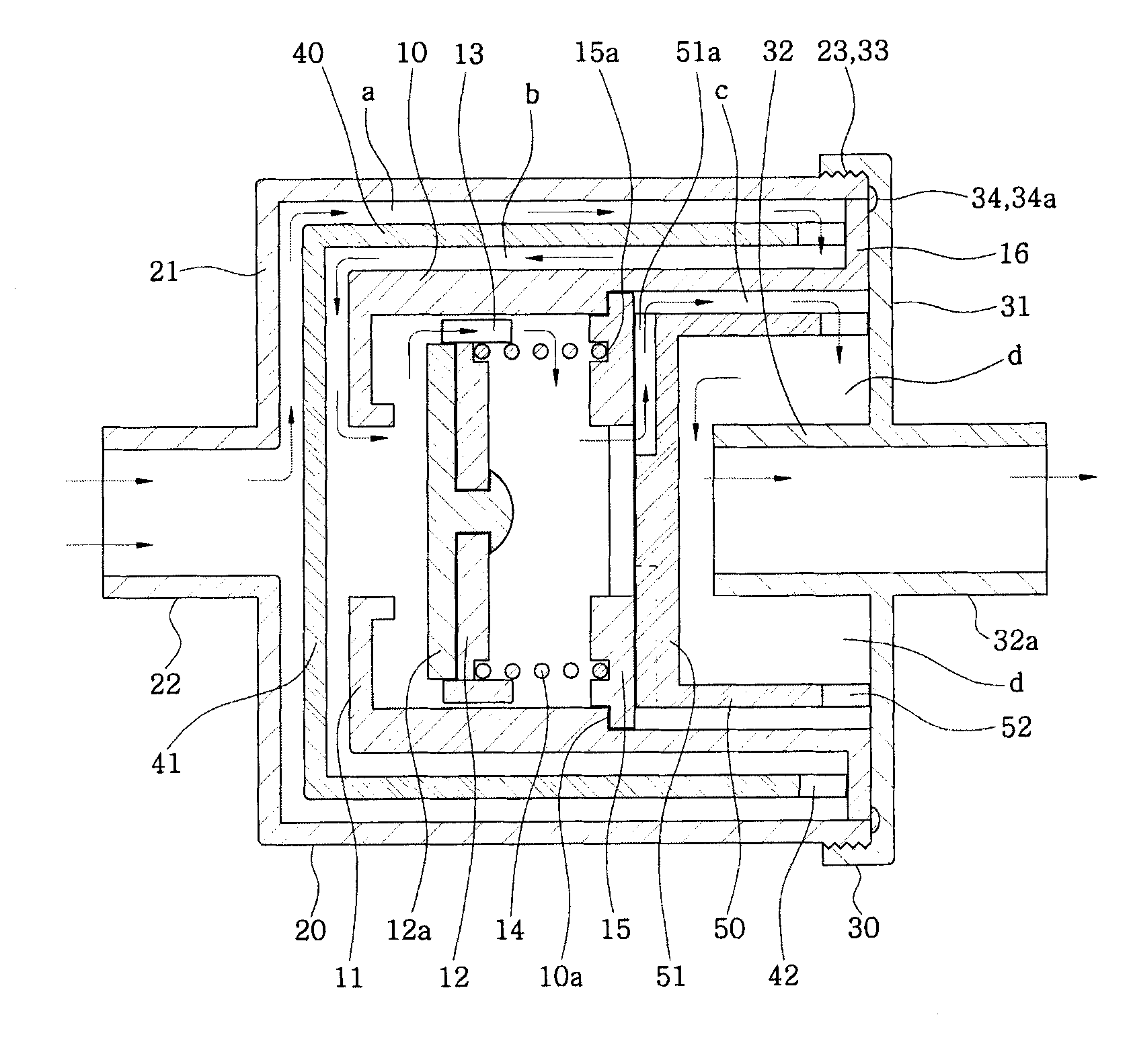

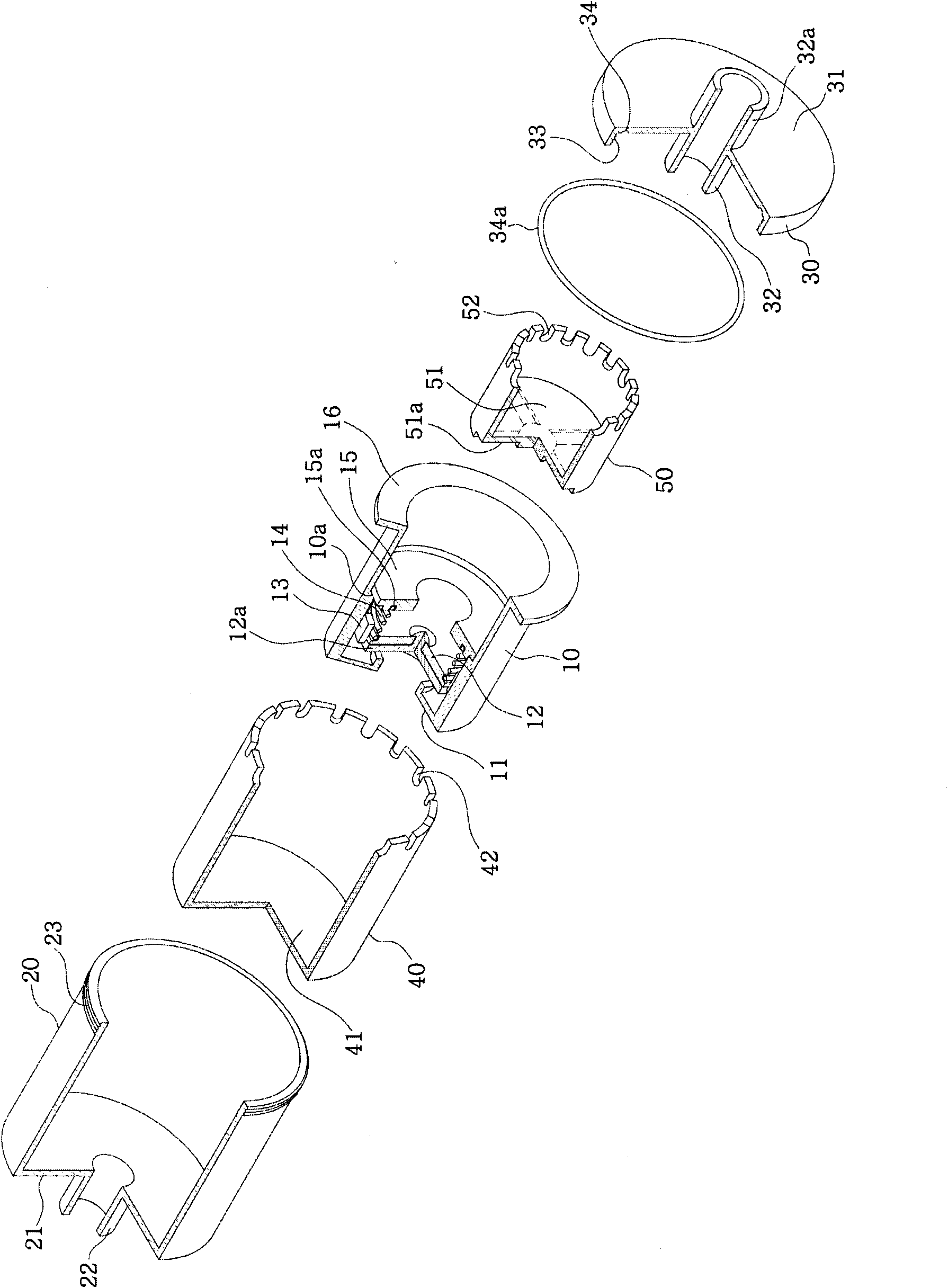

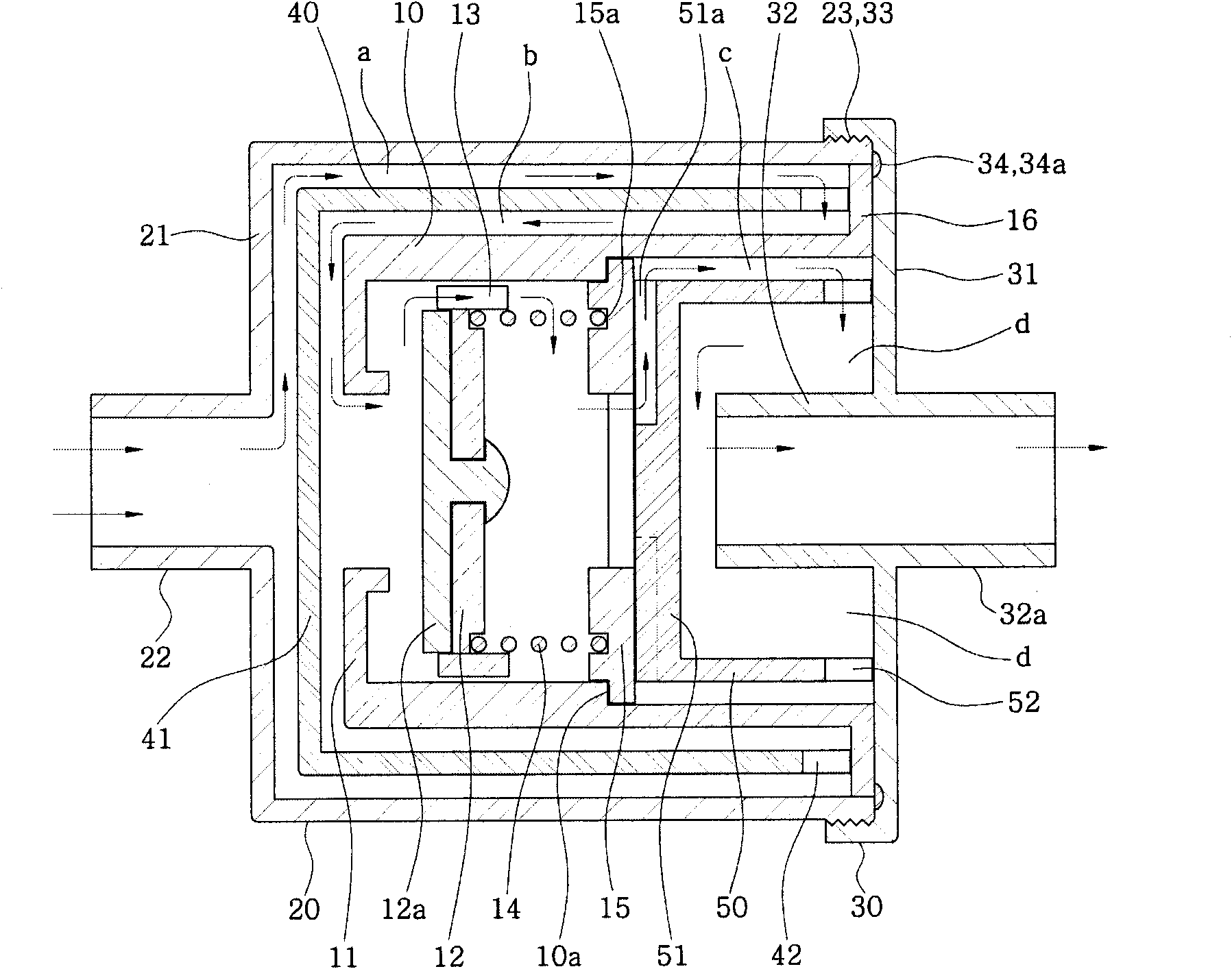

[0018] The noiseless check valve for small hot water boilers of the present invention is specifically described as inserting the left side gasket 12a close to the inner surface of the central through hole of the left side wall 11 of the cylindrical body 10 and inserting it toward the valve disc. The spring 14 on the inner surface of the strip-shaped protrusion 13 protruding from the right side of the edge of 12 is sleeved on the left side of the central through hole of the support disc 15 attached to the middle wedging end 10a of the inner surface of the open part on the right side of the cylinder 10 Formed in the circular band groove 15a, so that the valve disc 12 has an elastic valve switch device, a vertical flange 16 protrudes at a certain height from the right end of the outer surface of the cylinder body 10, and the vertical flange 16 As the center, on the left side, the upper end of the vertical flange 16 can be close to the diameter of the inner surface and the certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com