Structures and methods for electrically and mechanically linked monolithically integrated transistor and MEMS/NEMS devices

A device and mechanical technology, applied in the fields of electro-solid devices, semiconductor/solid-state device components, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve problems such as insufficient and incapable of reflecting the theme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

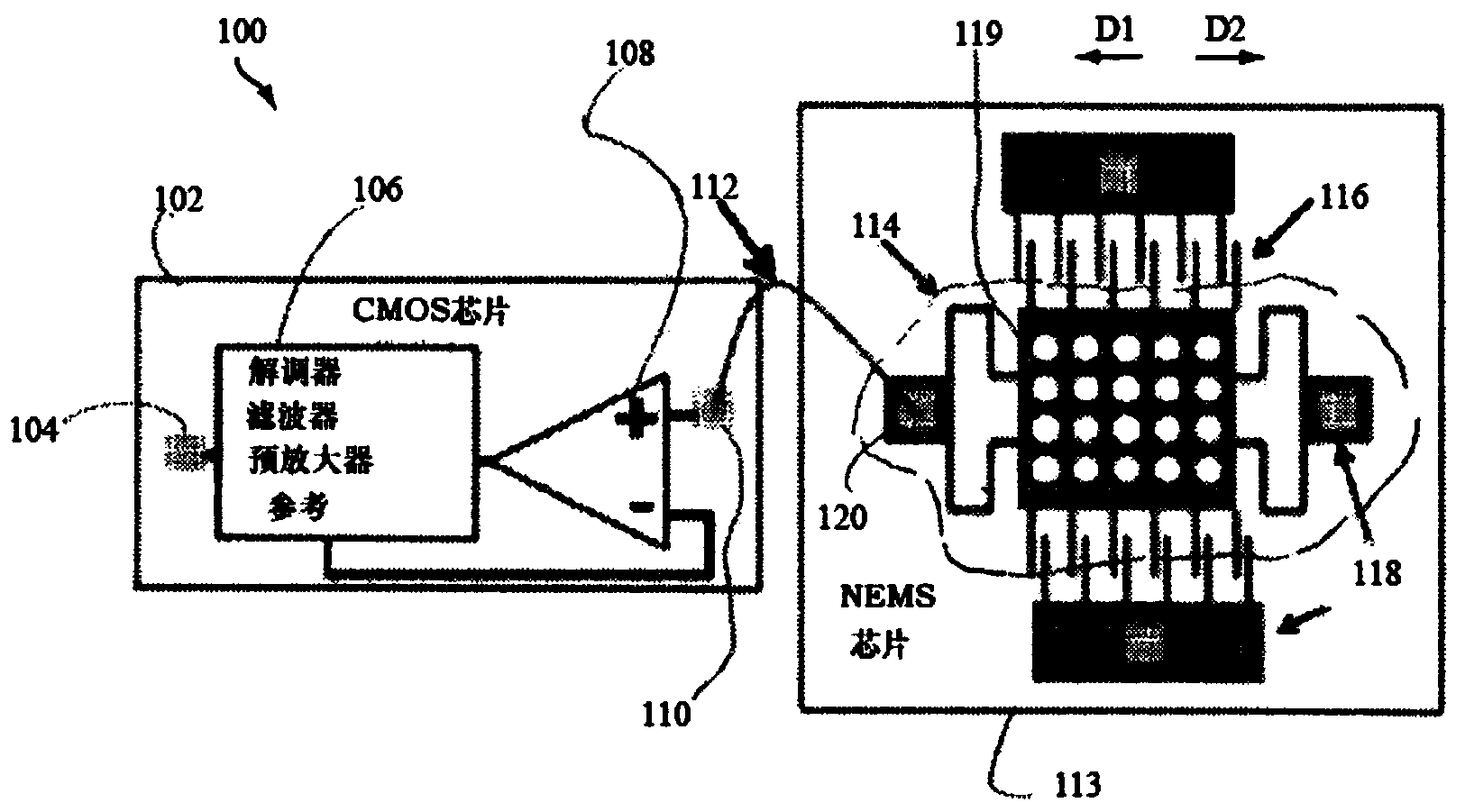

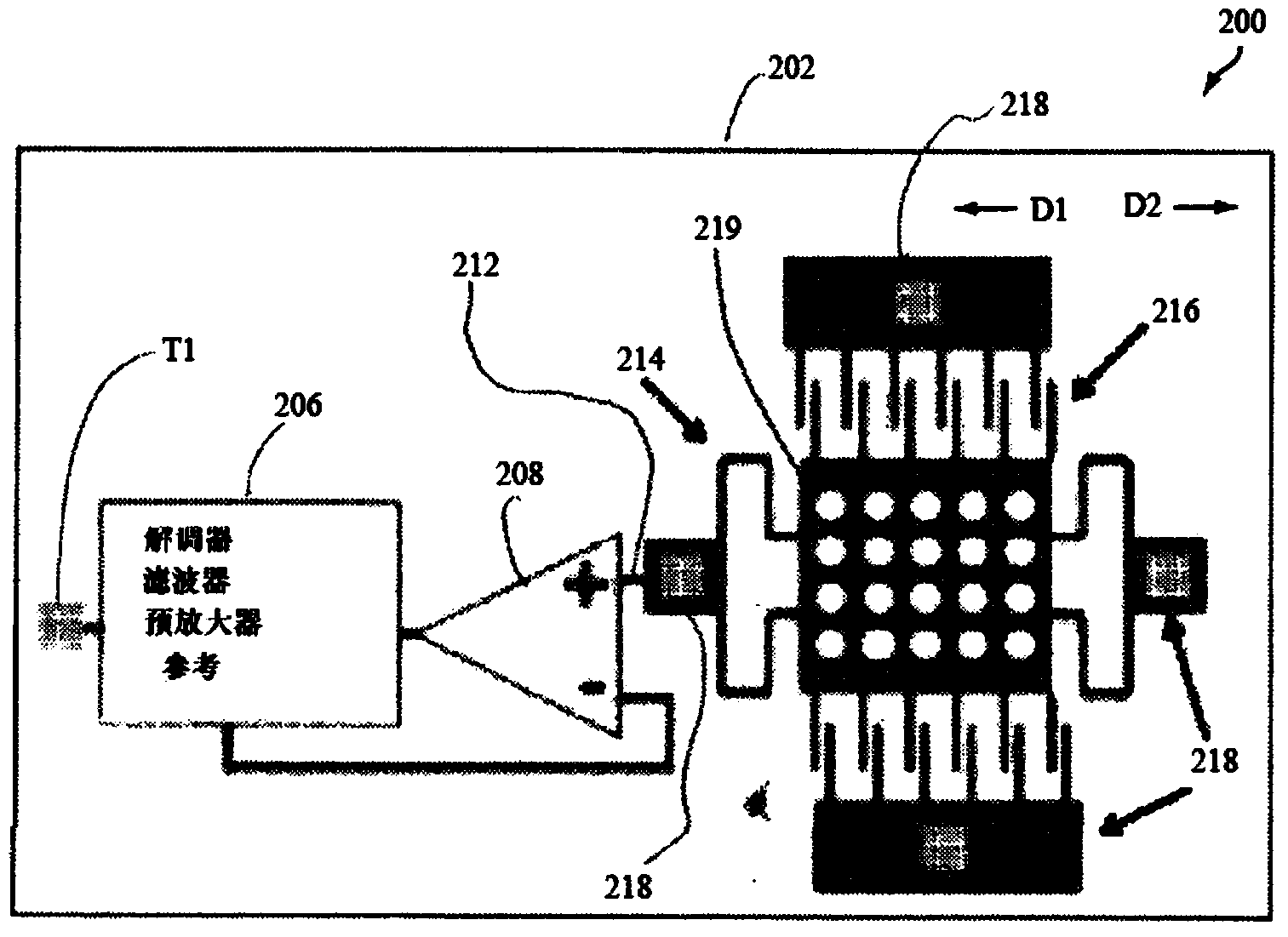

[0057] figure 2 A NEMS / MEMS device 200 is shown, which essentially consists of a single monolithically integrated chip 202 . In some embodiments, the NEMS / MEMS device may include additional control electronics, such as a processing network, on the second chip substrate. However, in device 200 , the NEMS / MEMS machinery and at least one transistor associated therewith are located on a single chip 202 . Such as figure 2 As shown, chip 202 includes: first terminal T1; demodulator / filter / preamplifier / reference module 206; amplifier 208; non-bonding path 212; fixed anchor structure 218; spring / mass subassembly 214; block 219; and finger structure 216.

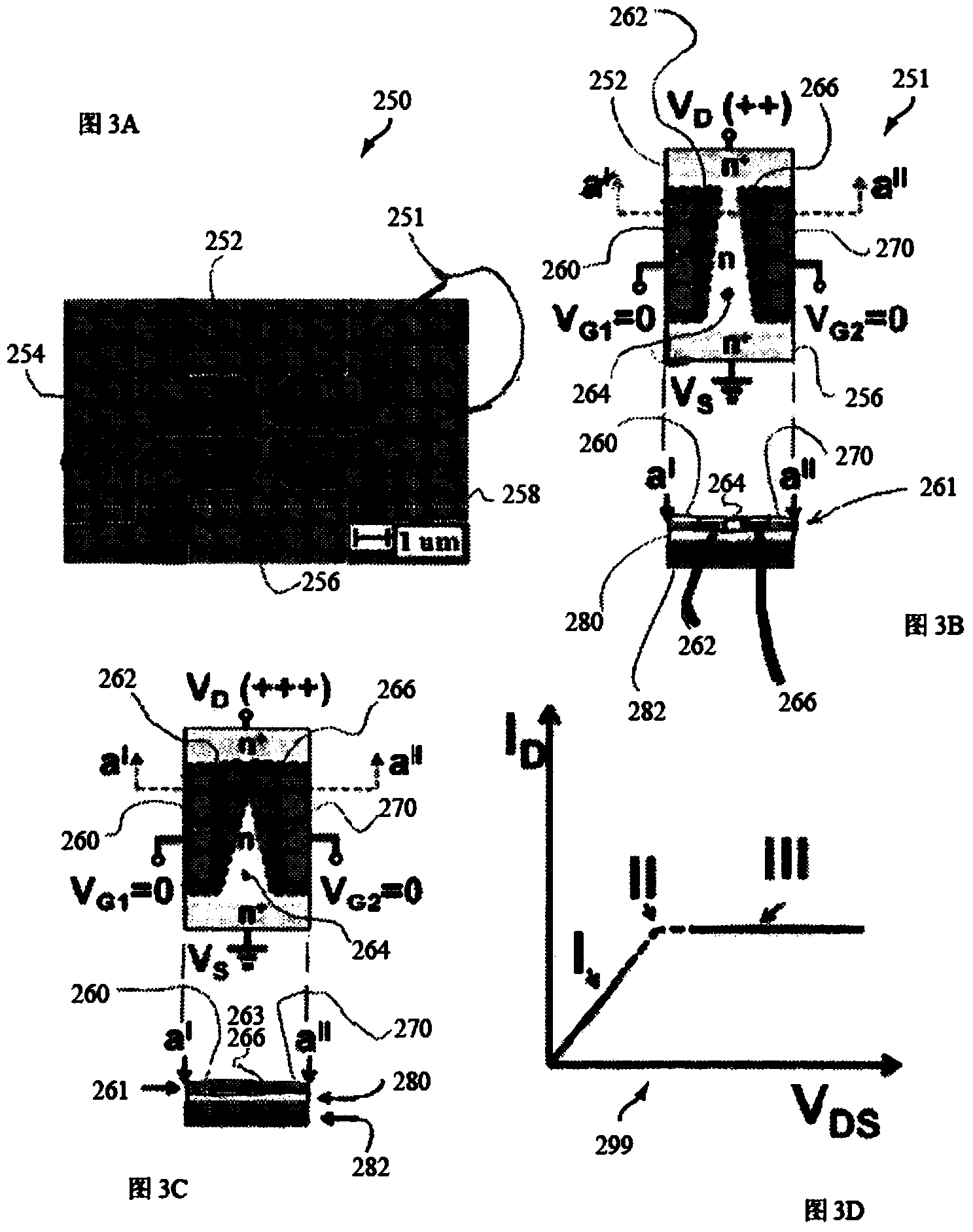

[0058] now refer to Figures 3A to 3D Modes of operation of NEMS / MEMS devices according to the present invention are discussed. Such as Figure 3A As shown, JFET 250 includes a drain region 252 ; a first gate region 254 ; a source region 256 ; a second gate region 258 and a channel region 251 . Such as Figure 3B and 3C As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com