Strong overload environment-oriented lens mounting structure optimal parameter design method

A technology of lens installation and optimal parameters, applied in installation, calculation, electrical and digital data processing, etc., can solve problems such as large amount of calculation, and achieve the effect of small amount of calculation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

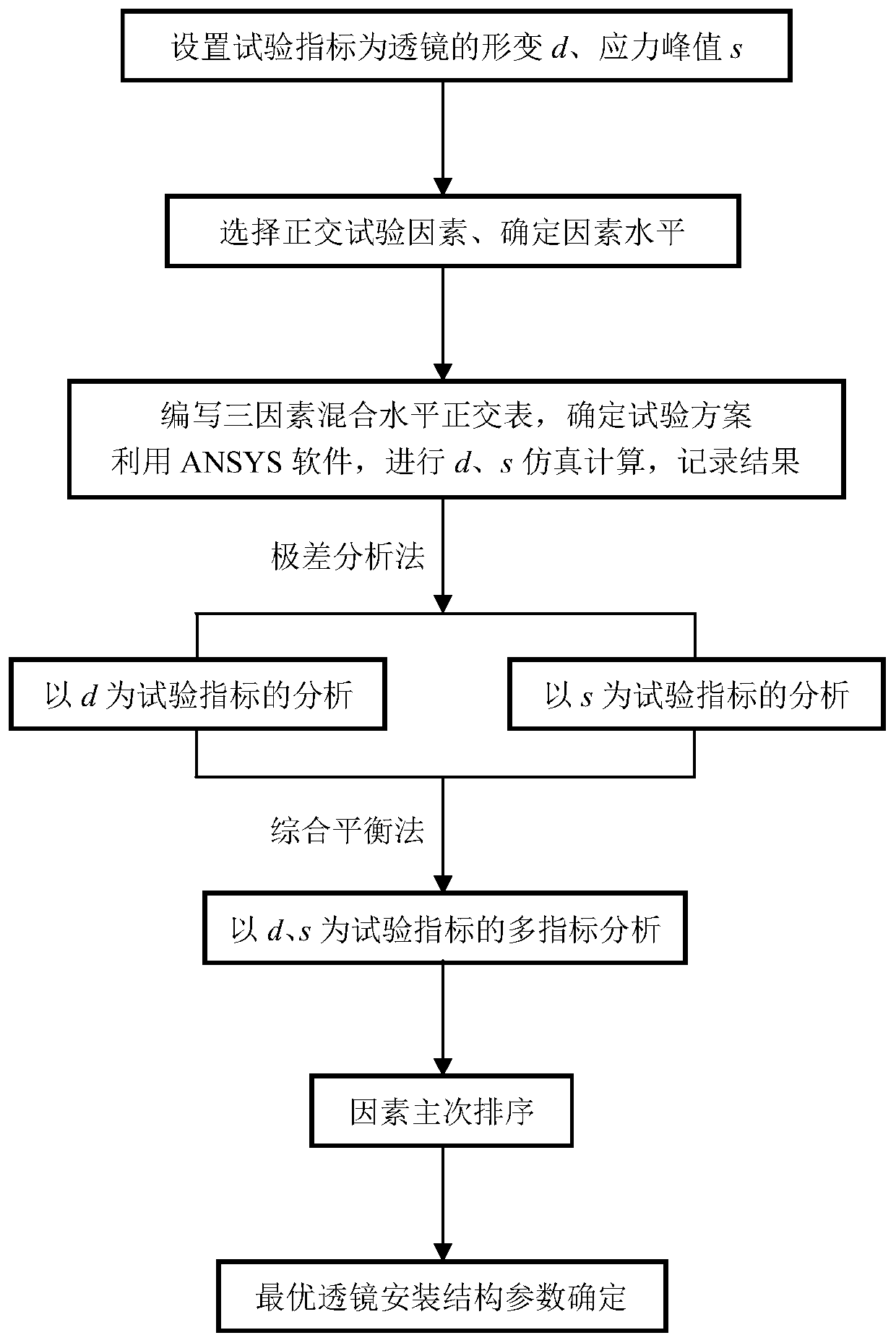

[0046] Such as figure 1 As shown, a method for optimal parameter design of lens installation structure under strong overload environment, including the following steps:

[0047] Step 1. Determine the corresponding test index according to the structural design requirements of the optical-mechanical system and the principle of minimum deformation and stress in the strong overload environment; in this embodiment, the determined simulation test index is 10000g gravitational acceleration overload, 10ms impact duration Deformation and stress peak value of optical lens in time.

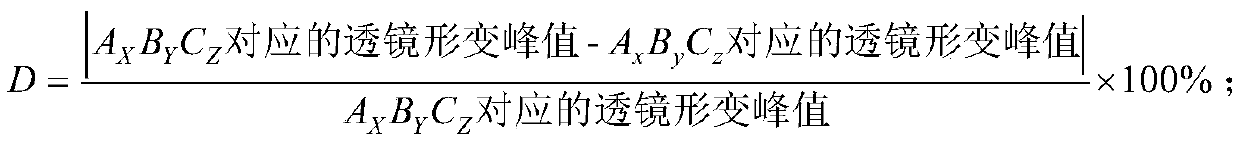

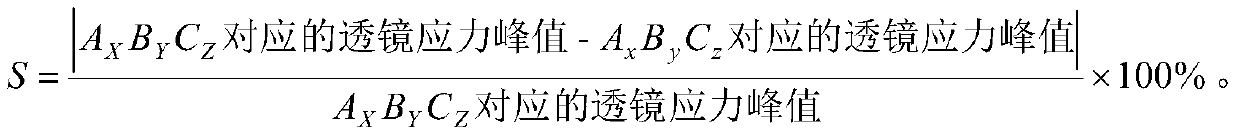

[0048] Step 2. Select the lens installation structure parameters as the test factors, and determine the number of levels of each factor according to the value range of the factors. The specific implementation method is: the lens material, gasket thickness and The three most important optimization parameters of the pre-tightening force are used as the experimental factors, in which the level number of the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com