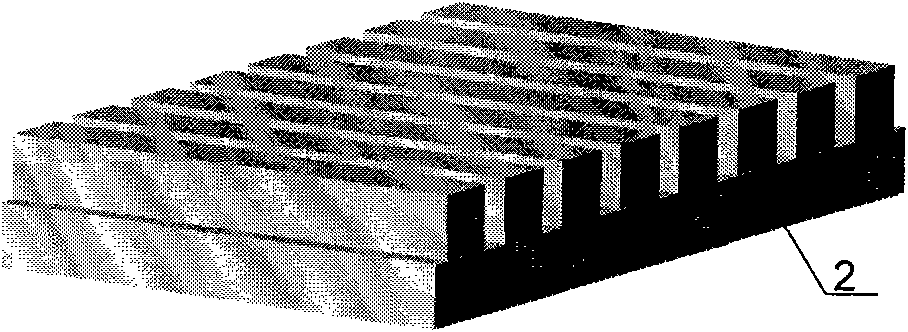

Method for designing stable superhydrophobic surface of grating structure

A super-hydrophobic surface and grating structure technology, applied in the direction of surface/boundary effects, calculation, special data processing applications, etc., can solve problems such as state transition without in-depth study of critical depth calculation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

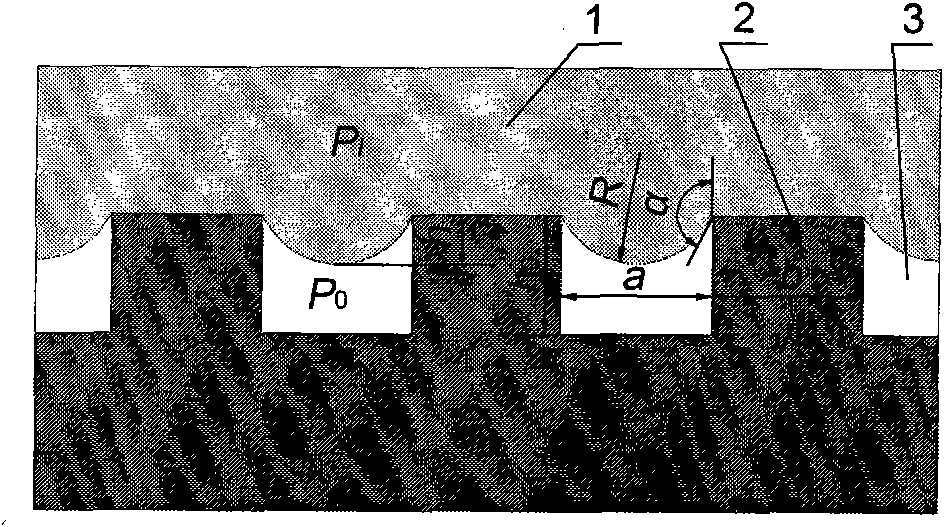

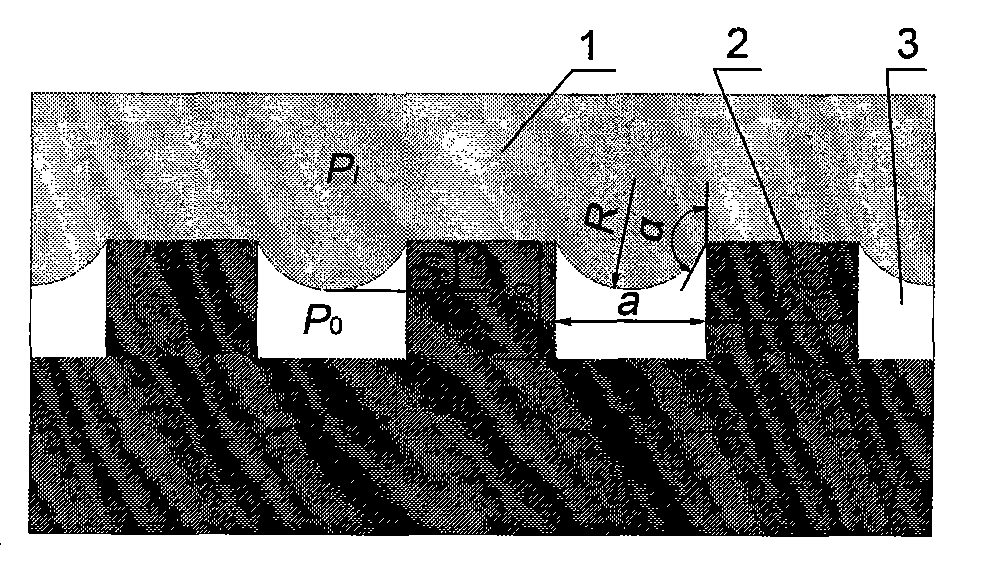

[0030] Embodiment 1 (contact angle is 150 °, intrinsic contact angle and advancing contact angle are 110 °, solid-liquid interface pressure difference is 1kPa, γ lg =72mN / m)

[0031] According to the requirement of contact angle and formula (3), the parameter f=0.2036 in formula (2) can be obtained. Then the structural parameters a=100 μm and b=25.07 μm are pre-designed according to formula (3). After determining the parameters a and b, according to the working state of the liquid (the internal pressure of the liquid P l ) and the Laplace deformation formula (4) determine the angle α between the liquid surface and the groove wall = 134.0°. The angle is as figure 2 As shown, at the same time, formula (5) is used to calculate the distance h=20.19 μm from the lowest point of the liquid surface to the top of the protrusion as shown in the figure. Since α>θ A , the liquid is unstable on the superhydrophobic surface, and the state transition from Cassie mode to Wenzel mode wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com