Collet of gem nozzle for ultrahigh-pressure water cutting

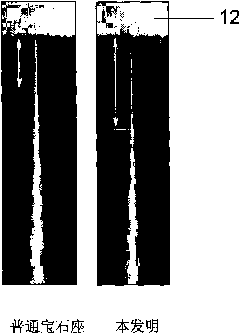

A technology of ultra-high pressure water cutting and gemstones, which is applied in the direction of spray guns, metal processing equipment, manufacturing tools, etc. With economical and other issues, to achieve the effect of increasing the effective target distance, reducing the degree of jet diffusion, and lengthening the length of the waterline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

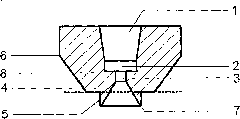

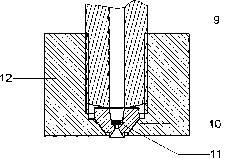

[0011] combine figure 1 , the gem seat is made of No. 45 steel, including inlet flow channel 1, gem embedding hole 2, outlet flow channel A3 and outlet flow channel B4, special profile of the seat body 5 (outline below the dotted line), common profile of the seat body 6 (dotted line Above profile), gem seat body 8. The inlet channel 1 is designed to be tapered, and the cone angle is between 15° and 30°. Downstream of the inlet flow channel is a cylindrical gemstone inlay hole 2, which can be inlaid with a gemstone 10 (ruby or sapphire) and a metal ring 11 around it. Below the jewel embedding hole 2 is the outlet flow channel of the gem seat, which is divided into two parts. The outlet flow channel A3 is cylindrical, and the outlet flow channel B4 is tapered gradually. Such outlets have good streamlines. In order to ensure the effect that is beneficial to enhance the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com