Multi-energy laminated inner container thermal storage tank

A hot water storage tank and multi-energy technology, applied in solar thermal power generation, heating devices, fluid heaters, etc., can solve problems such as unsatisfactory, affecting the comfort of water heaters, and ineffective use of hot water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

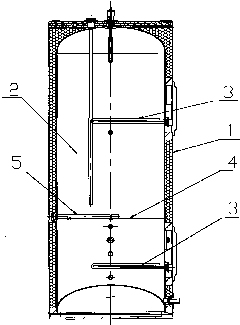

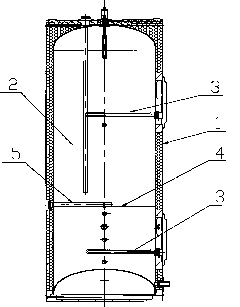

[0008] As can be seen from the drawings, the multi-energy layered tank for hot water storage includes an outer shell 1, an inner tank 2, and an electric heating tube 3 installed on the inner tank 2. The plate 4 and the liner 2 are fixedly equipped with a partition pole 5, and stainless steel screws can be used for fastening between the mesh partition 4 and the partition pole 5. In the present invention, a dividing plate is added in the middle of the water tank to divide the water tank into upper and lower layers, and many tiny through holes are opened on the mesh dividing plate to ensure that the water tank communicates up and down. In the state of rapid or large amount of water consumption in the family, cold water enters the lower water tank, and the mesh partition can intercept the unmixed cold water in the lower layer to prevent the cold water from directly rushing to the upper layer. Using the stratification principle of cold and hot water, the hot water in the upper layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com