A blowout-proof water separator for drilling and discharging water and its working method

A technology of detecting and discharging water and water separators, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., which can solve problems such as damage to drilling rig equipment, impact on people's personal safety, crowd impact, etc., and improve diversion Effect, the connection method is simple and stable, and the effect of reducing the amount of outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

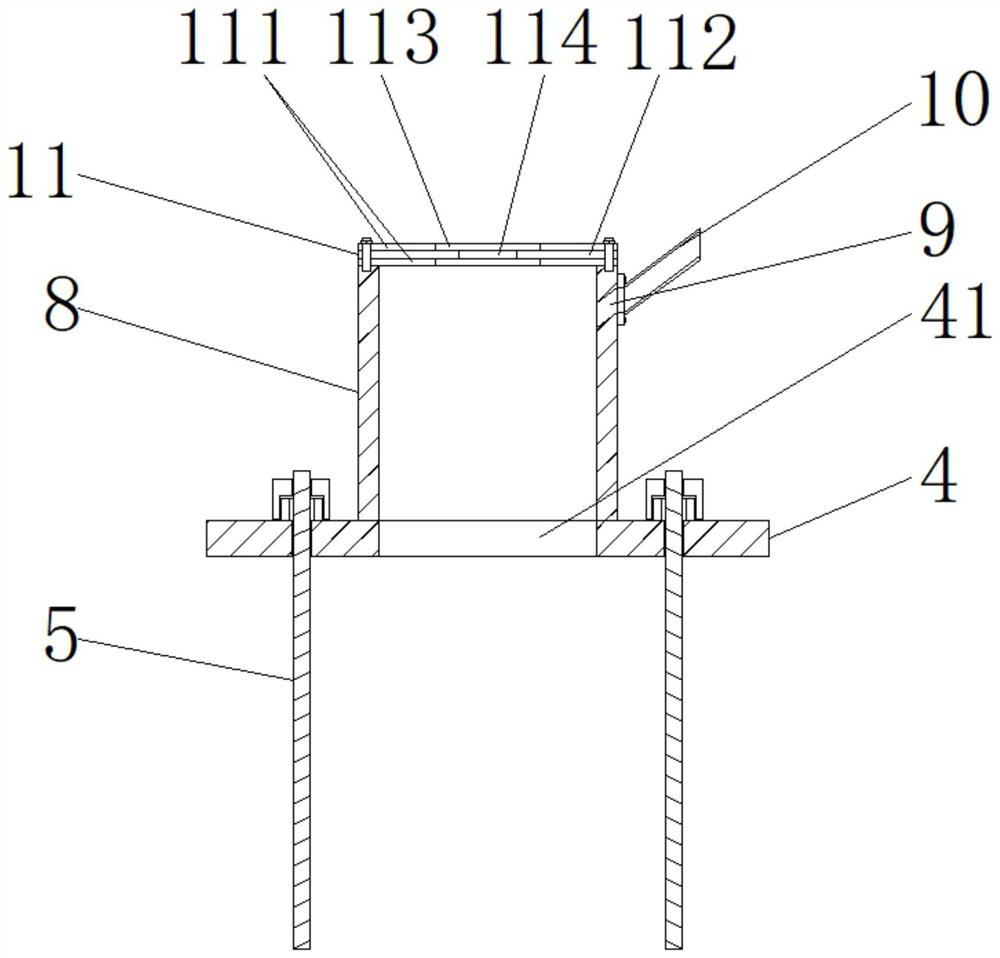

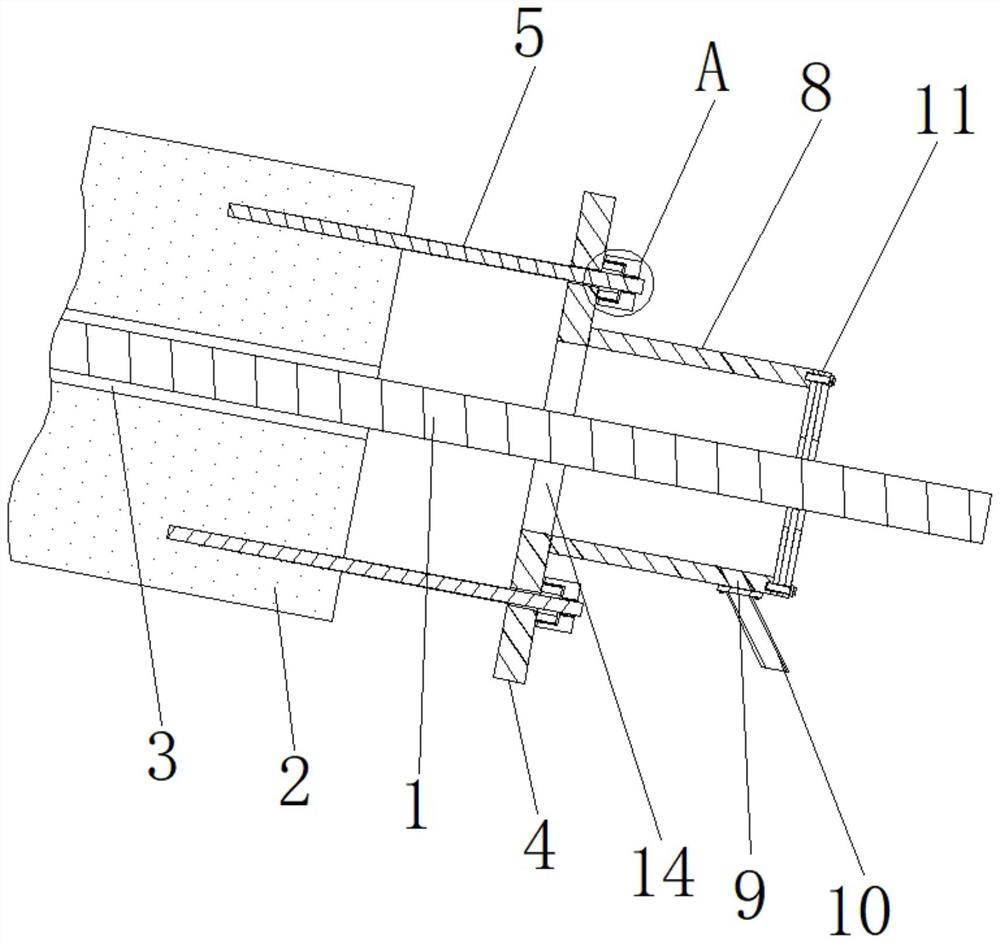

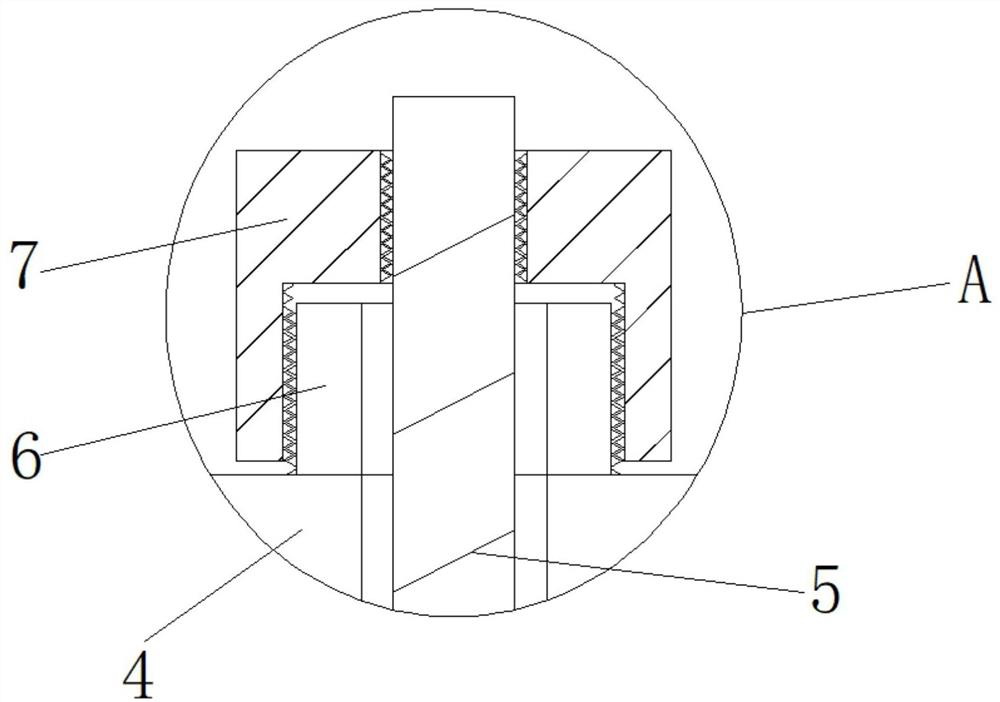

[0035] like Figure 1-6 Shown a kind of water exploration and drainage hole blowout preventer, including drill pipe 1, ore body 2 and drill hole 3, the drill pipe 1 is inserted into the ore body 2 through the drilling rig equipment and forms a drill hole on the ore body 2 3. The port of the borehole 3 located on the outer wall of the ore body 2 is provided with a shunt mechanism for guiding and shunting the gushing water flow inside the borehole 3. The shunt mechanism includes a fixed plate 4 with a circular hole 41 in the center, which is fixed on a fixed plate. The diversion cylinder 8 on the disk 4 and in the annular structure, the diversion cylinder 8 is hollow inside and the upper and lower ends are open, and the diversion cylinder 8 and the circular hole 41 are arranged concentrically, and the inner diameter of the diversion cylinder 8 is equal to the circular hole 41 The diameter of the diversion cylinder 8 and the circular hole 41 is larger than the diameter of the bor...

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 is that, as Figure 7-9As shown, the bottom end of the fixed plate 4 is provided with a protective mechanism for gathering the water flow at the lower end of the circular hole 41. The adjustment mechanism on the flow cylinder 8 and the telescopic adjustment of the bellows 12, the upper port of the bellows 12 is fixedly connected with the bottom end of the fixed plate 4 through the upper connecting ring 13, and the lower port of the bellows 12 is fixedly connected with the borehole 3. The lower connecting ring 16, which covers the port, can cover the area between the port of the borehole 3 and the fixed plate 4 through the corrugated pipe 12, so that more water flowing from the borehole 3 can flow into the guide tube 8, in order to reduce the outflow of the water flow from the lower port of the diversion cylinder 8, improve the gathering effect of the water divider on the gushing water flow, and at the same time enhanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com