Preparation method of gcl vertical anti-seepage wall

An anti-seepage wall, L-shaped technology, applied in construction, infrastructure engineering and other directions, can solve the problems of high construction difficulty and cost, the anti-seepage effect cannot meet high environmental protection requirements, and the consumption of raw materials is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of GCL vertical anti-seepage wall, is characterized in that, comprises the steps:

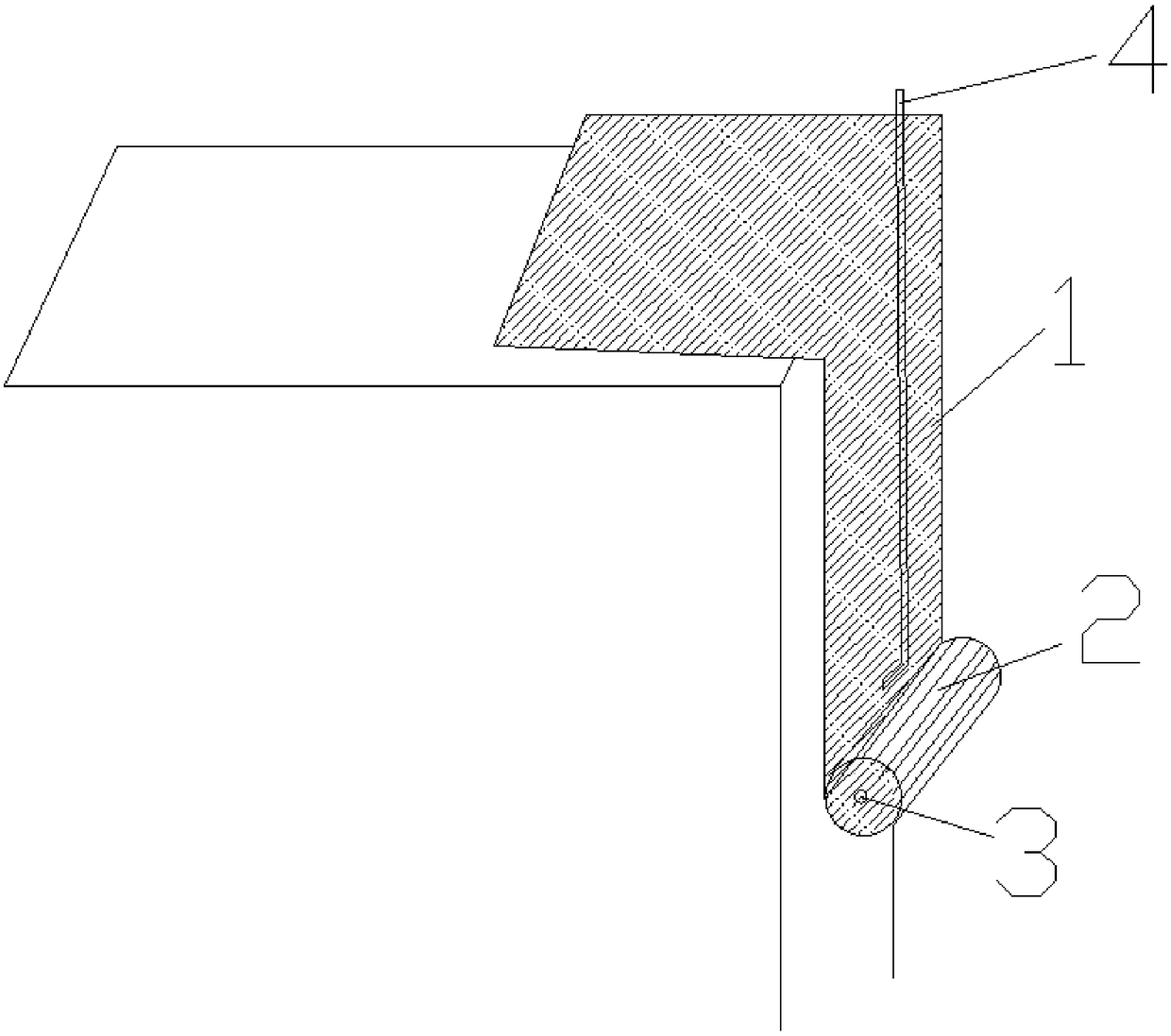

[0024] Excavate the trench; roll the GCL with a round pipe with the required counterweight and fix one end of the GCL on the top of the trench, insert it vertically downward along the dug trench wall, and the length of the GCL is greater than the The depth of the trench; then slowly open from top to bottom and lay along the wall to the bottom of the trench and fix the GCL against the wall, then take out the round pipe and pour grout into the trench The material is solidified into a wall to form the GCL vertical anti-seepage wall.

[0025] The above schemes can already complete the preparation of the vertical cut-off wall of GCL, and the preferred scheme is given below,

[0026] Preferably, the said GCL is slowly opened from top to bottom and laid along the wall to the bottom of the groove, and the GCL is fixed to the wall by using an L-shaped push piece to a...

Embodiment 1

[0036] A kind of GCL vertical anti-seepage wall construction technology, comprises the following steps:

[0037] Excavation trench: Excavate a trench with a width of 50cm around the garbage dump, and the trench penetrates 60cm into the impermeable layer vertically. The purpose is to form an overall anti-seepage system and prevent leachate from seepage from the lower end of the anti-seepage wall;

[0038] The laying of GCL is to insert the GCL vertically downward along the excavated trench wall. In order to ensure that the GCL is inserted into the bottom of the trench, the GCL cut 1.5 meters longer than the depth of the trench is rolled into a roll with a counterweight steel pipe and anchored at the top first. 1.8 meters, and then slowly open and lay along the wall from top to bottom; in order to ensure that the GCL is laid flat and smoothly opened downward, the L-shaped steel pipe is used to slowly open the GCL roll downward along the groove wall, and after it is completely ins...

Embodiment 2

[0046] The difference from Example 1 is that the GCL used in this example is granular GCL, and its gram weight needs to be ≥ 4500g / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com