Device capable of automatically screwing for building installation

An installation and screwing technology, which is applied in the field of doors and windows, can solve problems such as time-consuming and laborious, screw deviation, and lower product quality, and achieve the effects of convenient operation, increased linkage, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

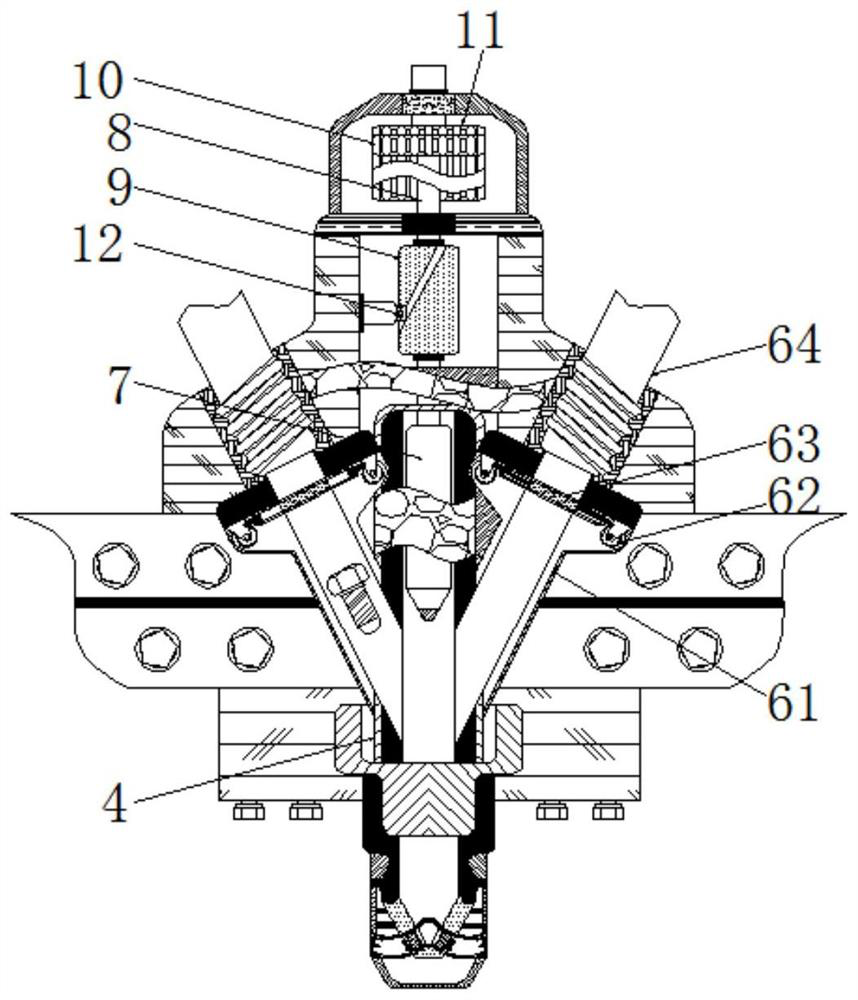

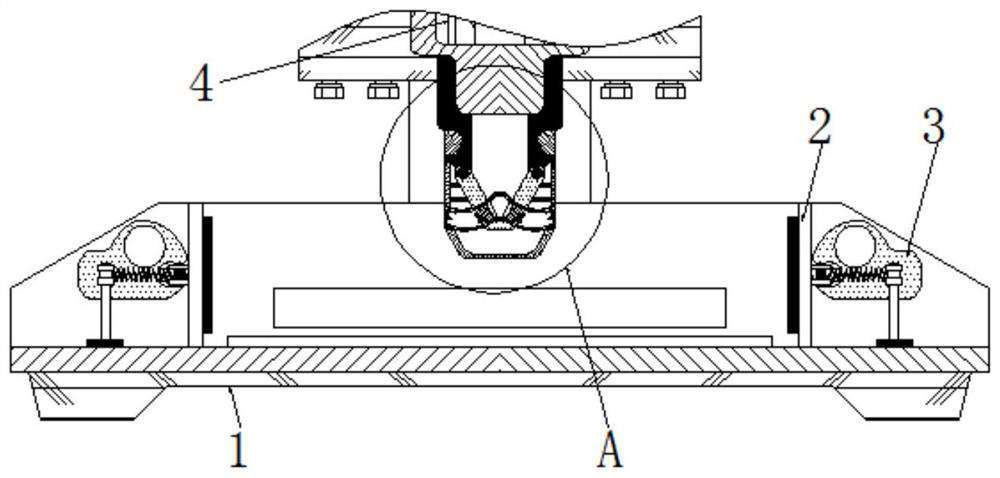

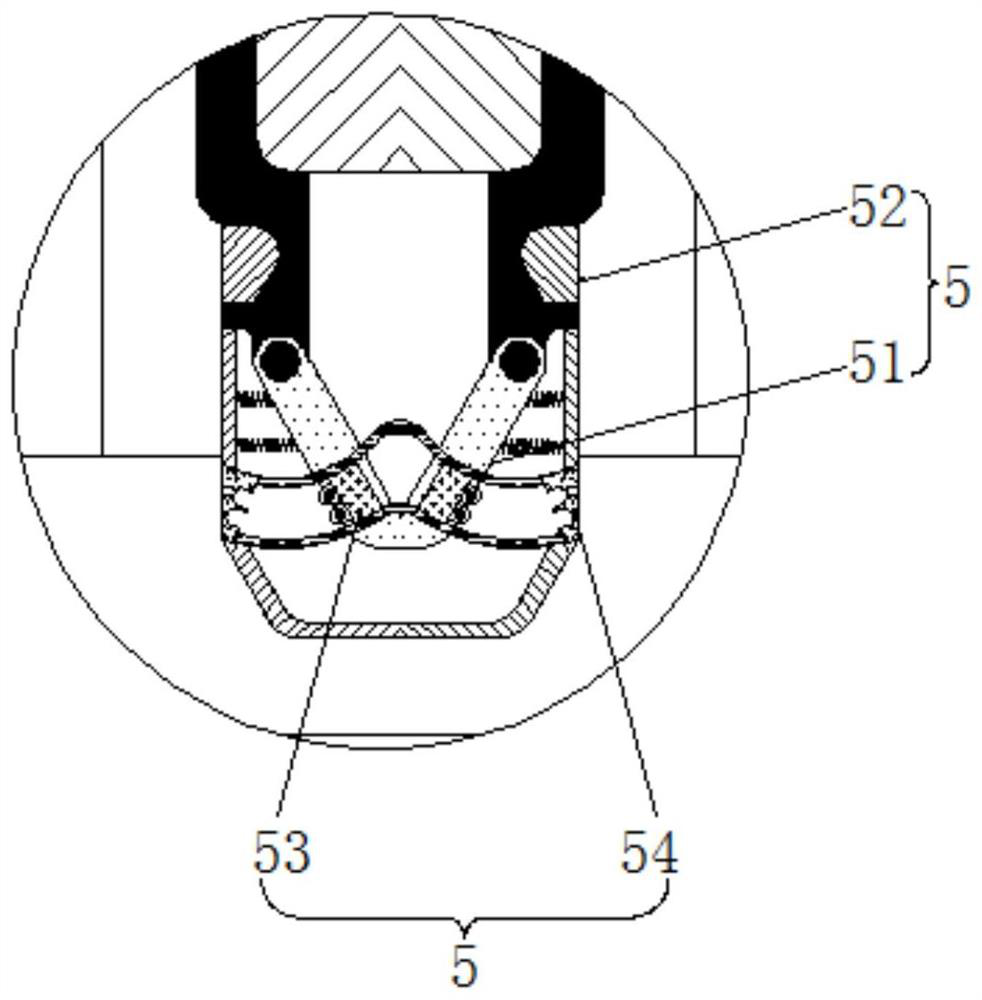

[0028] see figure 1 , a device for automatic screwing for building installation, including a base 1, a conveyor belt is arranged above the base 1, and the conveyor belt is used to drive the doors and windows to automatically transfer, the upper part of the base 1 is clamped with a limiting plate 2, and the limiting plate 2 The side end is rotatably connected with a cam 3, the upper part of the base 1 is fixedly connected with a screw sleeve 4, and the inside of the screw sleeve 4 is provided with a cavity, the size of the cavity is compatible with the size of the screwdriver head 7, and the outer surface of the screw sleeve 4 The mouthpiece mechanism 5 is sleeved on the surface, and the mouthpiece mechanism 5 includes a partition 51. There are two partitions 51. The specifications of the two partitions 51 are consistent, and the size of the spacer sleeve 52 is adapted to each other. At the same time, the partition A spring is arranged between the plate 51 and the limit sleeve ...

Embodiment 2

[0031] see figure 1 , a device for automatic screwing for building installation, including a base 1, a conveyor belt is arranged above the base 1, and the conveyor belt is used to drive the doors and windows to automatically transfer, the upper part of the base 1 is clamped with a limiting plate 2, and the limiting plate 2 The side end is rotatably connected with a cam 3, the upper part of the base 1 is fixedly connected with a screw sleeve 4, and the inside of the screw sleeve 4 is provided with a cavity, the size of the cavity is compatible with the size of the screwdriver head 7, and the outer surface of the screw sleeve 4 The surface is sleeved with a batch nozzle mechanism 5, and the two ends of the screw sleeve 4 are movably connected with a nail feeding mechanism 6. The nail feeding mechanism 6 includes a nail feeding tube 61, and there are two nail feeding tubes 61. The specifications of the two nail feeding tubes 61 Consistent, and symmetrically distributed with refer...

Embodiment 3

[0034] see Figure 1-4, a device for automatic screwing for building installation, including a base 1, a conveyor belt is arranged above the base 1, and the conveyor belt is used to drive the doors and windows to automatically transfer, the upper part of the base 1 is clamped with a limiting plate 2, and the limiting plate 2 The side end is rotatably connected with a cam 3, the upper part of the base 1 is fixedly connected with a screw sleeve 4, and the inside of the screw sleeve 4 is provided with a cavity, the size of the cavity is compatible with the size of the screwdriver head 7, and the outer surface of the screw sleeve 4 The mouthpiece mechanism 5 is sleeved on the surface, and the mouthpiece mechanism 5 includes a partition 51. There are two partitions 51. The specifications of the two partitions 51 are consistent, and the size of the spacer sleeve 52 is adapted to each other. At the same time, the partition A spring is arranged between the plate 51 and the limit sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com