Distal tibiofibular joint screw guide forceps

A technology for guiding pliers and joints, which is applied in the field of medical appliances and can solve problems such as inability to judge nails well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

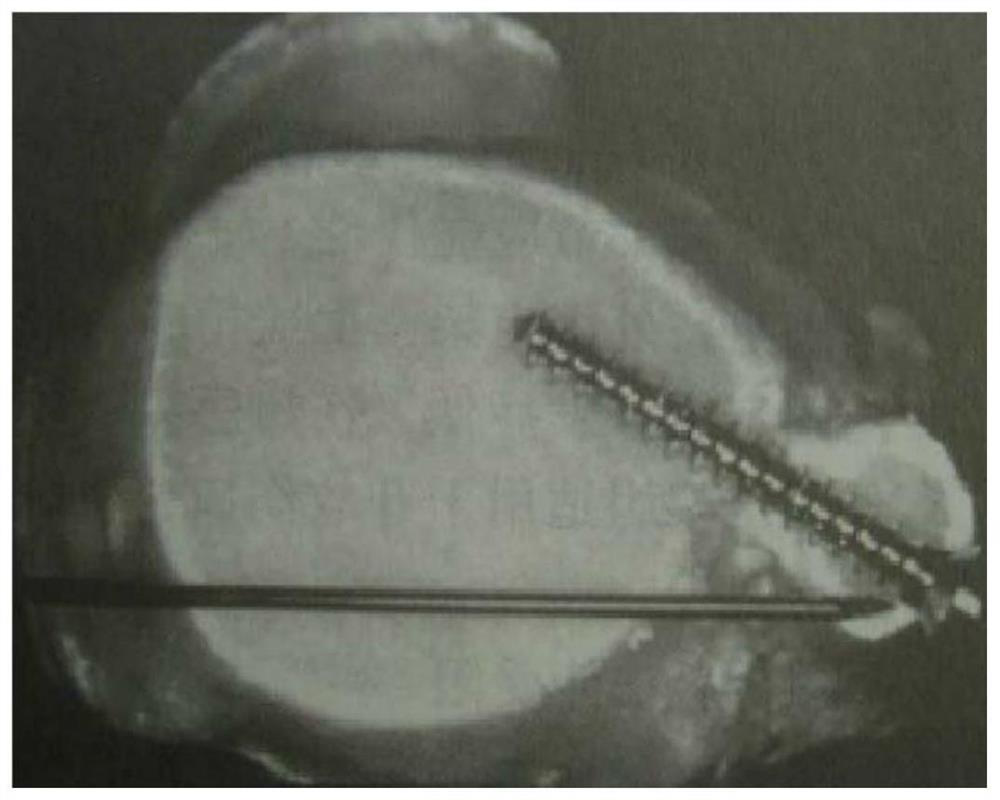

[0037] Such as Figure 4 , Figure 5 and Figure 6 As shown, the present invention provides a lower tibiofibular joint screw-guided forceps, comprising a handle 1 and a handle 2, the junction of the handle 1 and the handle 2 is connected by a rivet 3 in rotation, the One end of the pliers handle 1 and the pliers handle 2 are respectively integrally formed with a pliers mouth 11 and a pliers mouth 2 21, and the pliers mouth 1 1 and the pliers mouth 2 21 are both arranged to be curved inwardly;

[0038] The other end of the pliers handle 2 is welded with an arc-shaped plate 4, and the bottom of the arc-shaped plate 4 is provided with an arc-shaped clamping mechanism 42, and the arc-shaped clamping mechanism 42 includes an inner arc-shaped plate 421, a connecting plate 422 , the outer arc-shaped plate 423, the inner arc-shaped plate 421 is welded on the inside of the arc-shaped plate 4, and the handle-1 is located between the inner arc-shaped plate 421 and the outer arc-shaped ...

Embodiment 2

[0046] Roughly the same as Example 1, the differences are as follows:

[0047] Such as Figure 7-Figure 11 As shown, the outer sliding sleeve of the arc-shaped plate 4 and the inner arc-shaped plate 421 is provided with a sleeve 5, the outer wall of the sleeve 5 is welded with a round tube 6, and the inner end of the round tube 6 is facing the For the rivet 3, a threaded rod 51 is installed on the top of the sleeve 5, and the sleeve 5 is loosened and positioned by tightening the threaded rod 51.

[0048] By adopting the above-mentioned technical scheme, clamp the two points on the rear side of the tibia and fibula through the handle one 1 and the mouth one 11, clamp the two points on the front side of the tibia and fibula through the handle one 1 and the two points on the front side of the fibula through the handle one 1 Together with the forceps handle 2 and forceps mouth one 11 and forceps mouth two 21, it clamps the shin and fibula at four points in front and back contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com