Spine central keel full-bearing vehicle body

A full load-bearing, spine-type technology, applied in load-bearing body structures, vehicle components, upper structures of passenger cars, etc., can solve the problem that small-section rods have poor ability to withstand bending loads, cannot design diagonal braces, and lower keels Structural strength, stiffness and other bearing performance indicators

Inactive Publication Date: 2010-09-15

XIAMEN GOLDEN DRAGON BUS +1

View PDF0 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the strength, stiffness and rollover safety of the structure have been significantly improved compared with the semi-loaded body, and the weight of the body structure has also been reduced to a certain extent, due to the space rectangular frame (square frame) used in the middle section of the body, the structure Limited by the volume of the luggage compartment, it is not possible to design diagonal braces on the longitudinal vertical planes on the left and right sides. From a structural point of view, there are still unreasonable factors in the force, and the strength, stiffness and bearing capacity of the structure have not yet been maximized. play

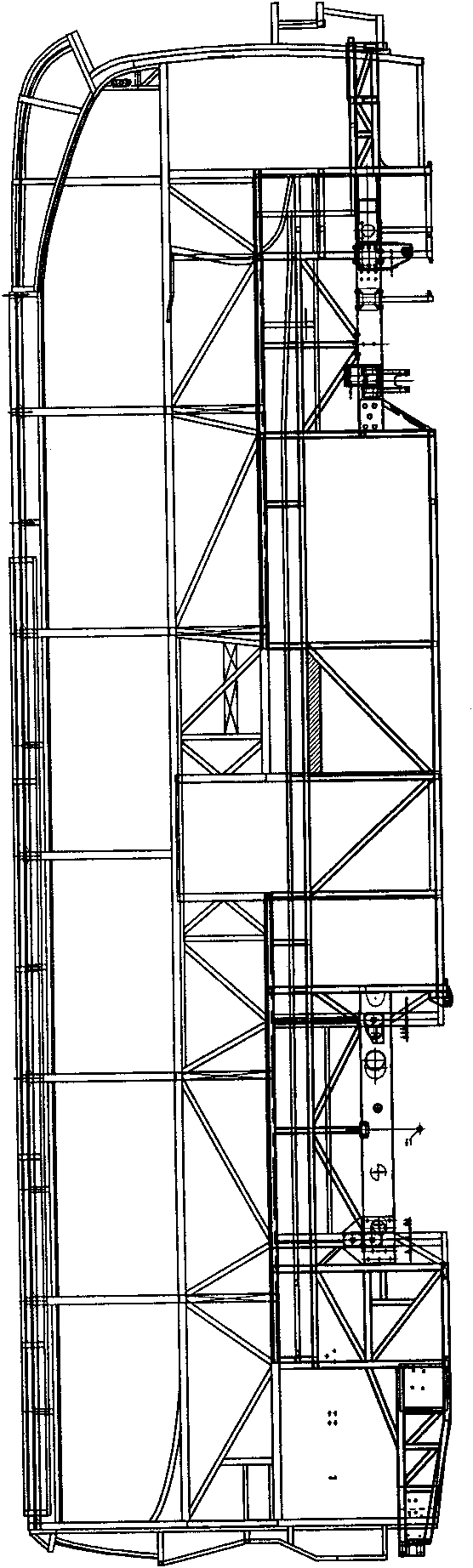

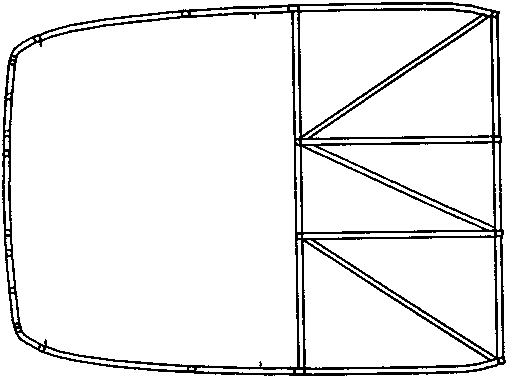

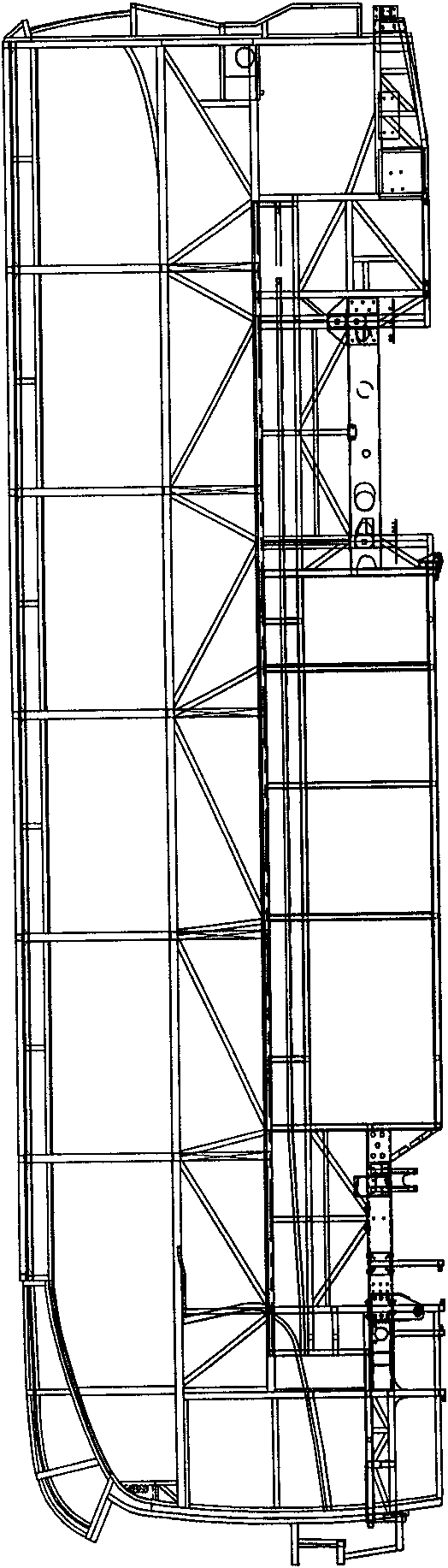

[0005] Existing load-bearing bus body structure (such as image 3 The middle section of the keel as shown) usually has a space rectangular frame 1' composed of 4 or 6 longitudinal steel pipes (rods). Except for special parts such as the middle door and toilet, the arrangement is left and ri

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a spine central keel full-bearing vehicle body, wherein the central keel comprises a driver zone floor framework, a front suspension zone framework, a middle piece framework, a rear suspension zone framework and an engine zone framework; the middle piece framework comprises a passenger floor framework, a storage room floor framework and a framework for connecting an upper floor and a lower floor; and the framework for connecting the upper floor and the lower floor is a planar frame which is composed of an upper beam, a lower beam, a plurality of longitudinal beams and a plurality of inclined struts, and the longitudinal beams and the inclined struts are arranged between the upper beam and the lower beam. In the invention, the frameworks symmetrically arranged on both sides of the keel are moved towards the middle to combine a planar trussed construction arranged on the left and right symmetric surfaces of the vehicle body, thus the truss arranged on the left and right symmetric surfaces of the vehicle body has no influence on the volume of the middle piece storage room with left and right openings no matter the inclined struts are provided or not. Therefore, the strength, the rigidity and the security of the vehicle body are greatly enhanced, and the utilization ratio is improved.

Description

technical field [0001] The invention relates to a passenger car body, in particular to a spine-type central keel full-carrying body. Background technique [0002] The bus body structure can be divided into non-load-bearing body, semi-load-bearing body and full-load body according to its load-bearing mode. With its advantages of light weight, high rigidity and good safety, the fully loaded body represents the mainstream direction of the development of bus body structure. The body structure of full-loaded passenger cars was proposed and designed by Setra for the first time. At present, Benz-Setra and MAN-Neoplan are mainly in the leading position in the full-loaded passenger car technology. [0003] Although there are obvious differences in the structural styles of Benz-Setra and MAN-Neoplan full-loaded car bodies, their structural forms belong to the same category from the perspective of structural mechanics. Space frame structures such as Figure 1A , Figure 1B Flat floo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B62D23/00B62D31/02

Inventor 姚成那景新李赫男彭庚庚丛盛芝蒋振宇张纲董丽娜韩甜峰纪碧端

Owner XIAMEN GOLDEN DRAGON BUS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com