Propeller for vessels

A technology for propellers and ships, applied in the directions of rotating propellers and rotary propellers, etc., can solve the problems of increasing the structural complexity and prolonging the time of assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

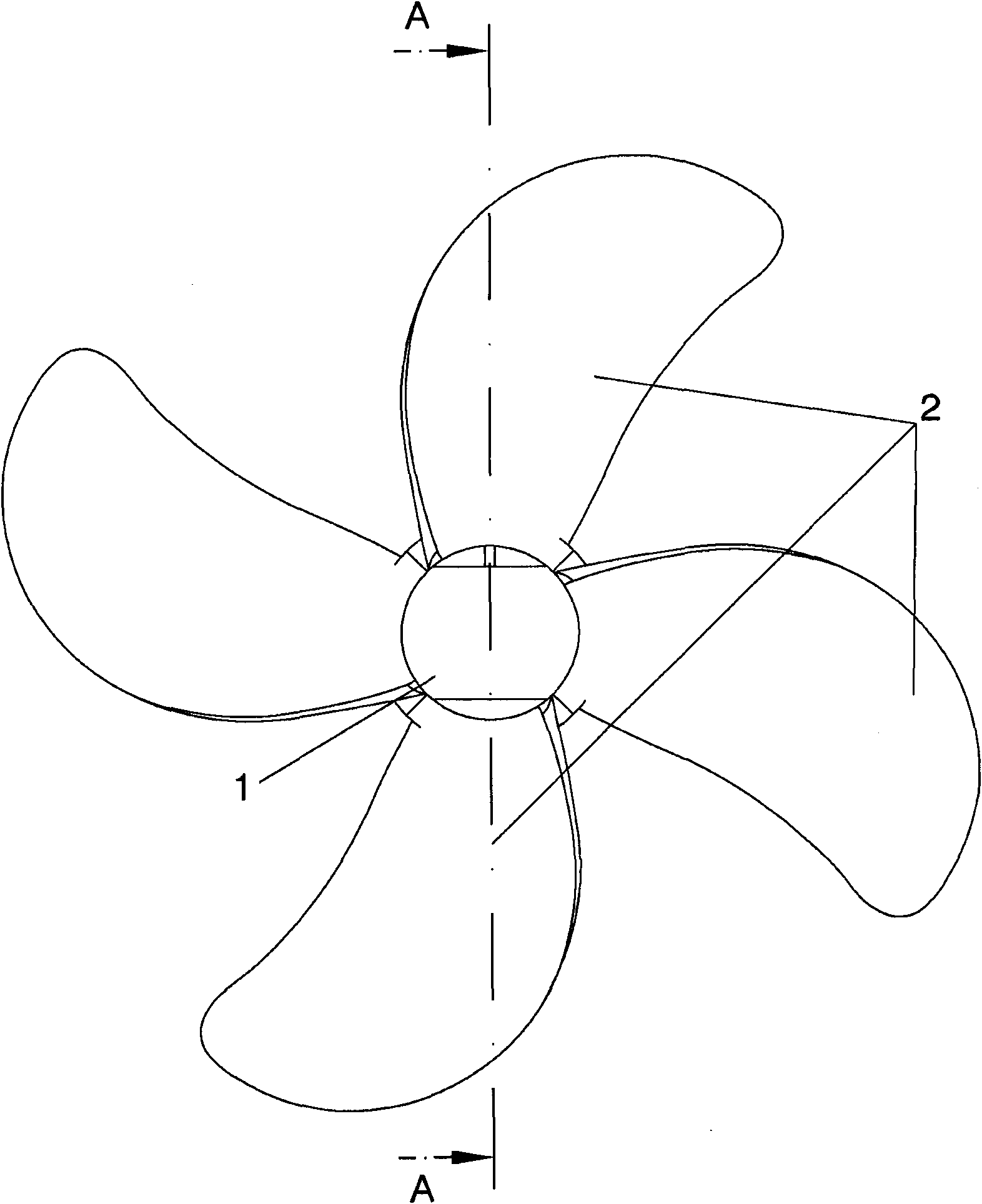

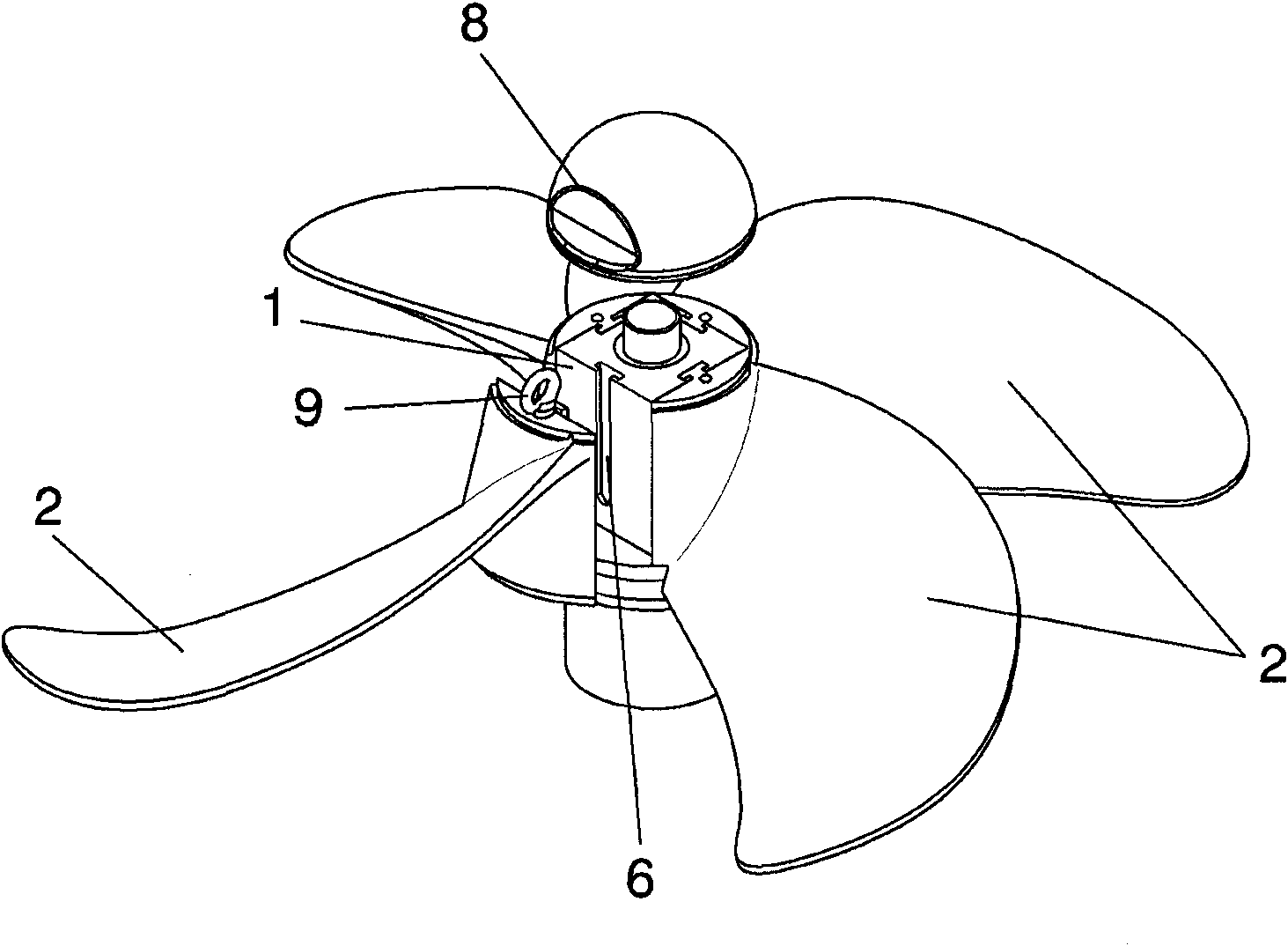

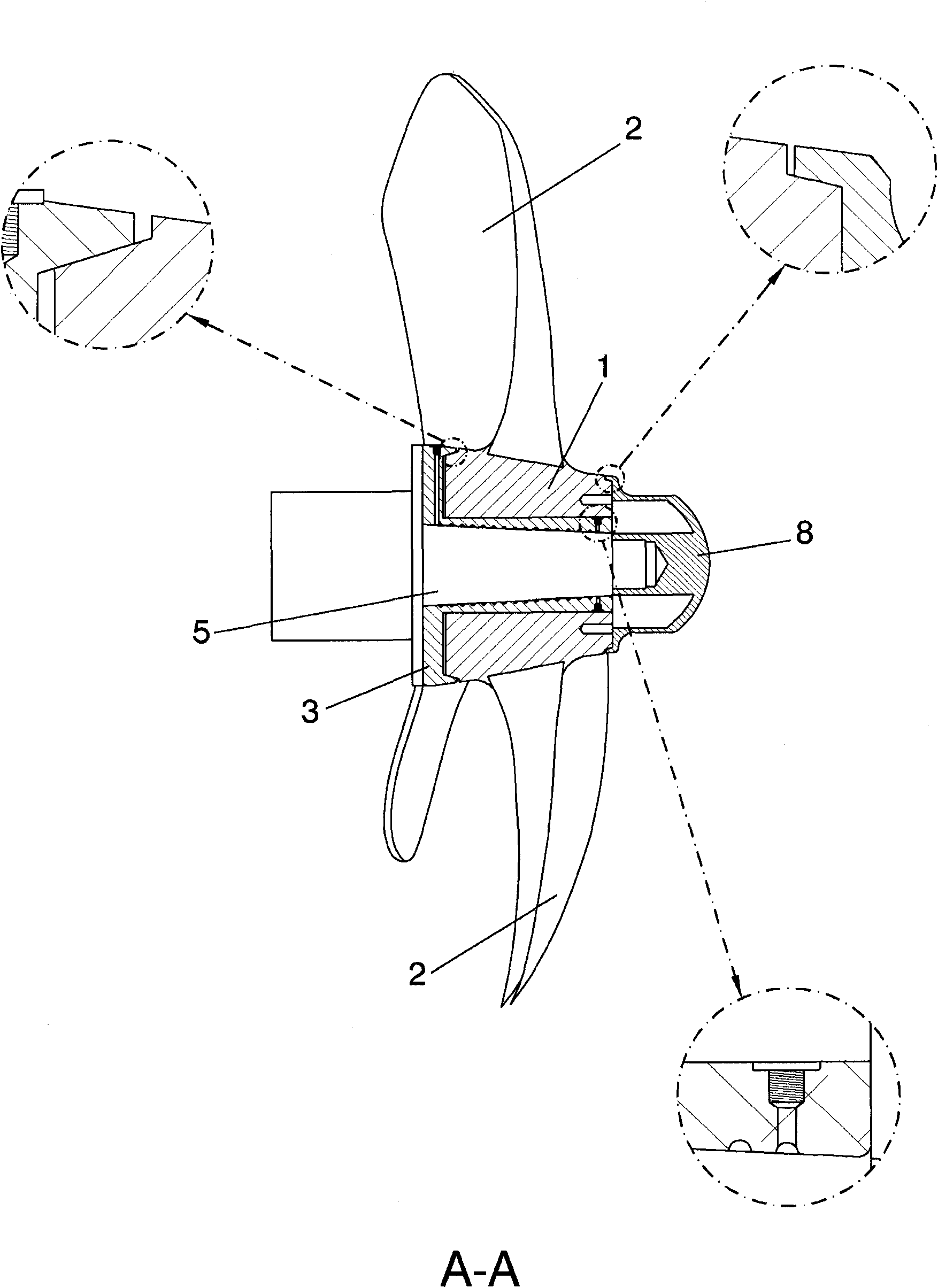

[0037] The attached graphics, especially Figures 1 to 7 , showing how the propeller of the present invention is constructed from the core device 1, which is specifically shown in Figure 5 , 6 and 7, chosen for the purpose of illustrating an example of a practical embodiment of the invention, are four paddles 2 arrangements, of quadrangular prism configuration, with a flange or The peripheral expansion 3, this flange will conform in shape and size to the aforementioned core means 1 and head 4 during the propeller assembly operation, whereby the blade 2 is fixed to said core means.

[0038] The core arrangement 1 has a shaft hole 5 (which is conventional) to couple the propeller to a transmission system which receives the motion from the respective engine. The essential feature of the invention is that each side of the core device 1 is provided with a groove 6, the groove in question extending parallel to the axis of the core device, passing through the center of said face, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com