Operating mechanism for controlling discharge outlet of furnace

A technology of operating mechanism and outlet, applied in the field of operating mechanism, can solve the problems of unstable long-distance operation, easily damaged plugs or outlets, and easy falling off of asbestos paper cups, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

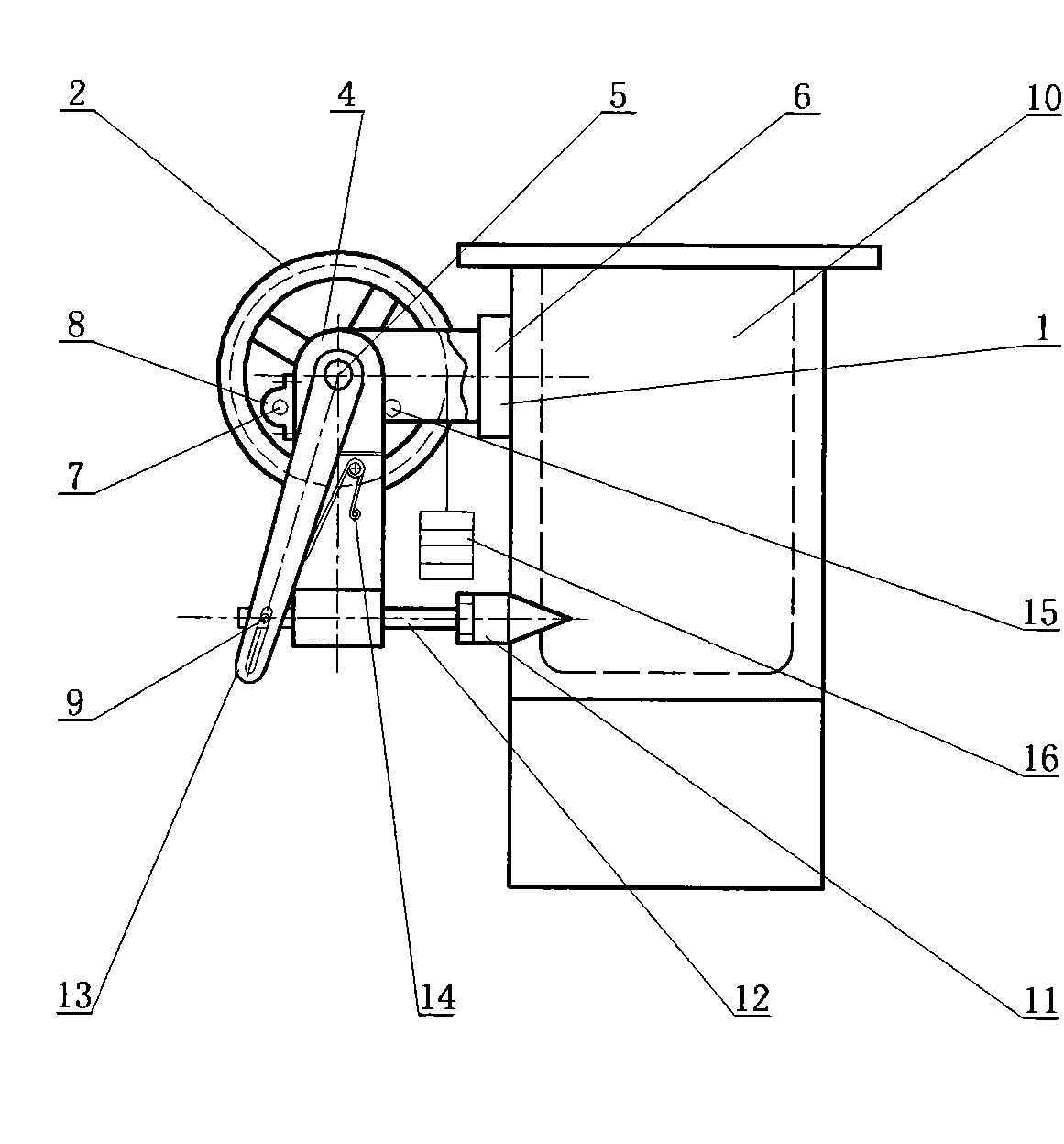

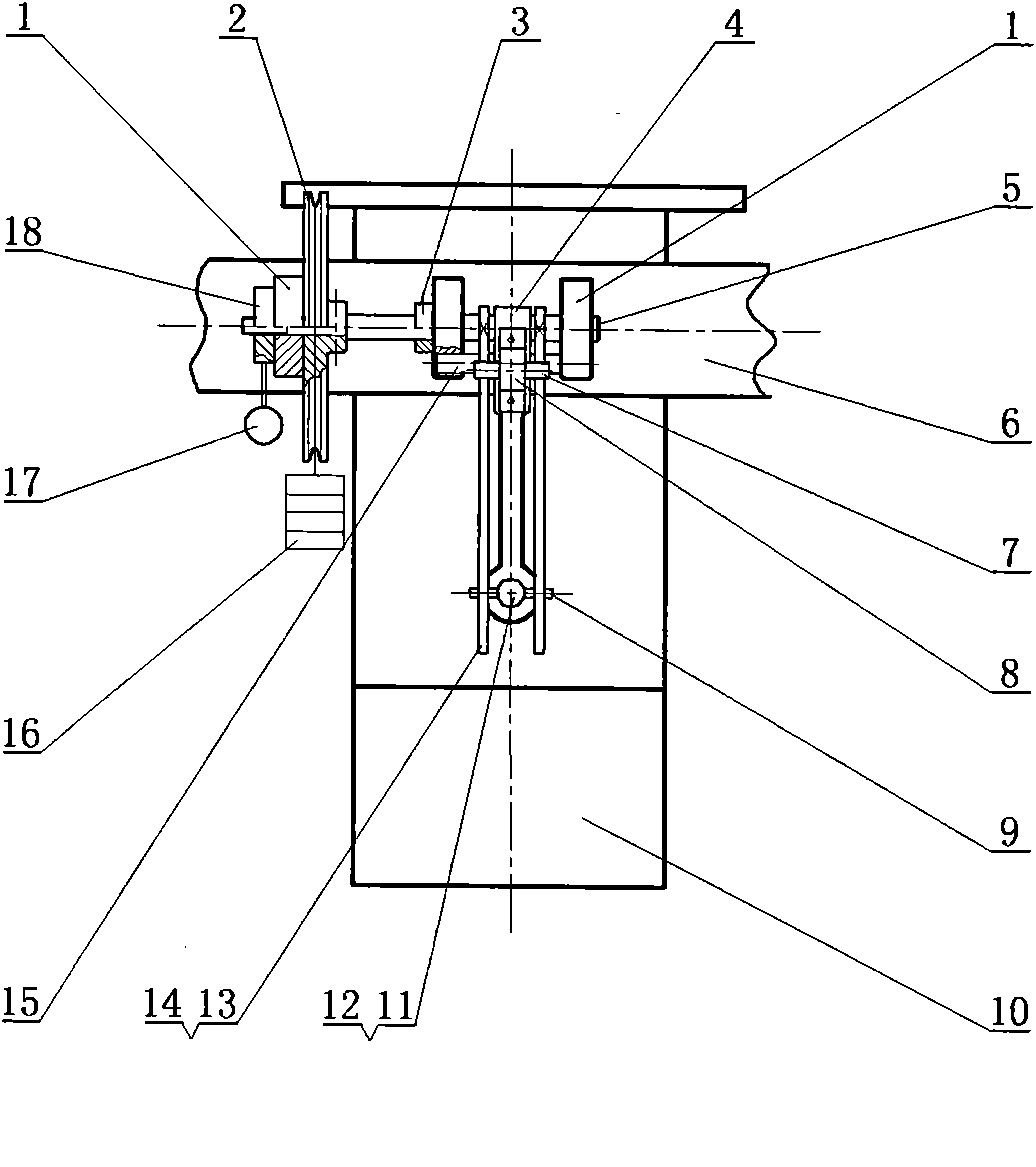

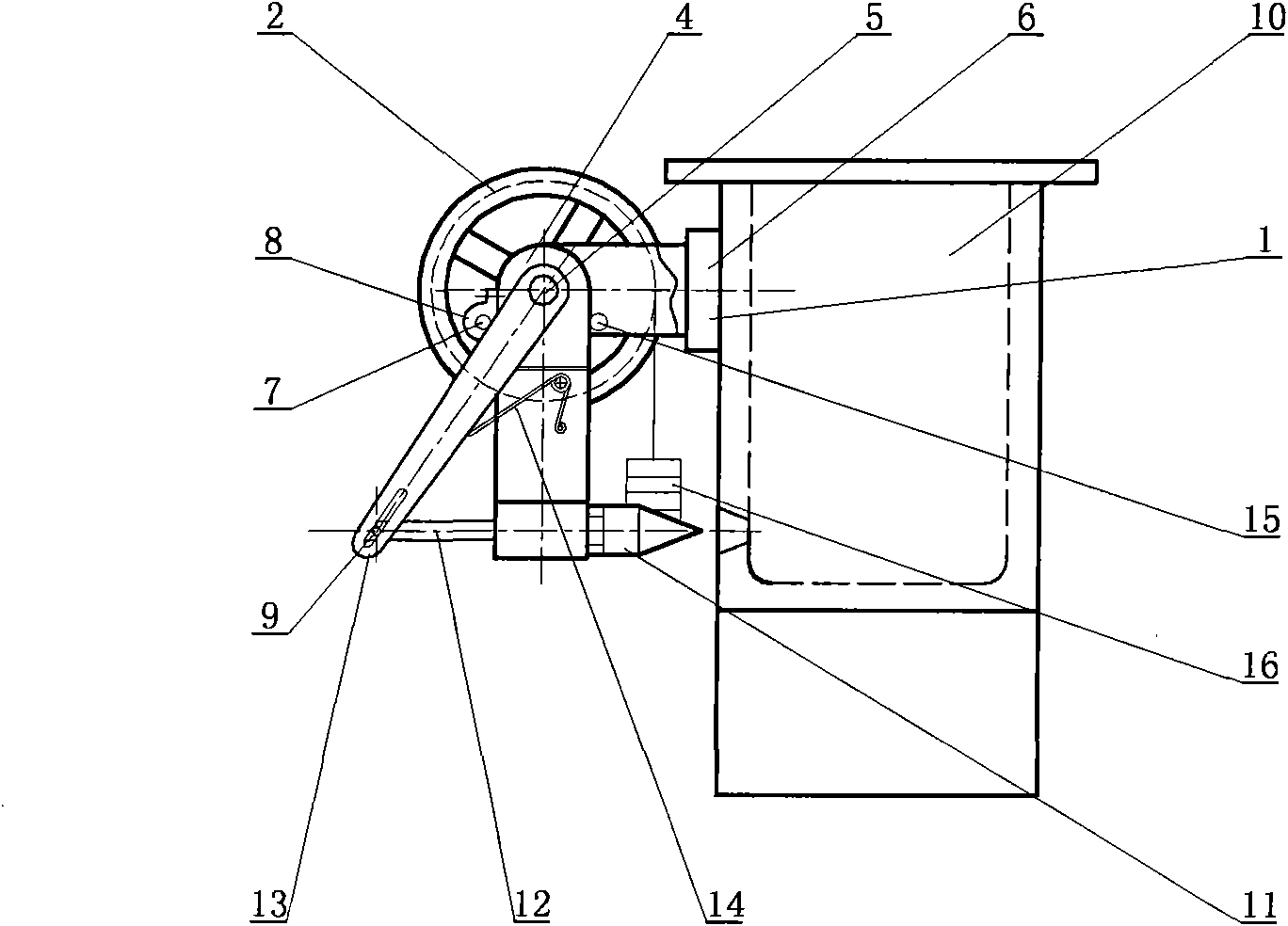

[0012] The present invention is an operating mechanism in the form of a mechanical structure, which solves the problem of translational movement and overturning of the plug [11] and can meet the use conditions of the discharge port of the melting furnace [10]. A fixed crossbeam [6] is set on the outside of the furnace [10], a set of support [1] is cantilevered, and is firmly horizontally installed on the crossbeam [6], and the front of the support [1] is provided with a mounting shaft [ 5], the through holes are horizontally arranged on the same axis, and a stop bar [15] is provided under the supports [1] on both sides of the installation body [4]; the rotating shaft [5] is a stepped shaft and a beam [6] Arranged in parallel, installed in dynamic fit with the support [1], using the adapter sleeve [3] to limit its axial displacement; the main body [4] is similar to a strip member, with mounting holes at both ends, and the centerline of the mounting hole is located on two planes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com