Offset printing output ink quantity reset method

An ink volume and offset printing technology is applied in the field of controlling the offset printing machine to preset the output ink volume and the offset printing machine output ink volume pre-adjustment field, which can solve the problems of ink paper and time waste, increasing production costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the pre-press workflow, RIP software or digital workflow software can generate PPF files or TIFF files from imposition files in PDF, EPS or PS formats, in order to calculate the graphics and text of each ink area more conveniently and accurately The coverage, the resolution of the generated PPF file or TIFF file should be set according to the characteristics of the offset printing machine, the purpose is to make the number of pixels per raster an integer. For example, Roland 700 offset printing machine is used in this example. The resolution of PPF file or TIFF file is 50.8PPI. If a 1-TIFF file is generated, the resolution is 300PPI, and the number of screening lines is 30 lines / inch.

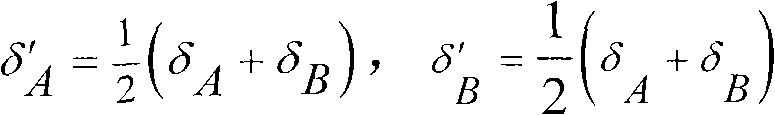

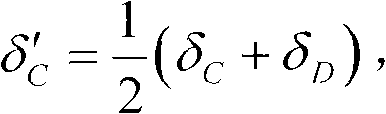

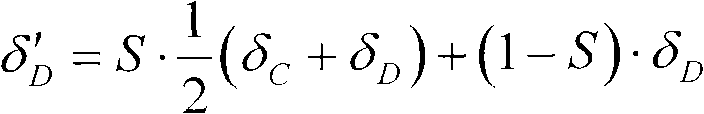

[0046] Use the input interface of the control computer to read in the PPF file or TIFF file generated before printing, input the width value of an ink area from the keyboard, take the centerline of the width direction of the digital image as the reference, and take the width of an ink ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com