Removal device for material separator

A technology of removing device and sorting machine, applied in sorting and other directions, can solve the problems of affecting the color sorting effect, difficult to collect, unable to effectively remove, etc., and achieve the effect of solving drift and accurate removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

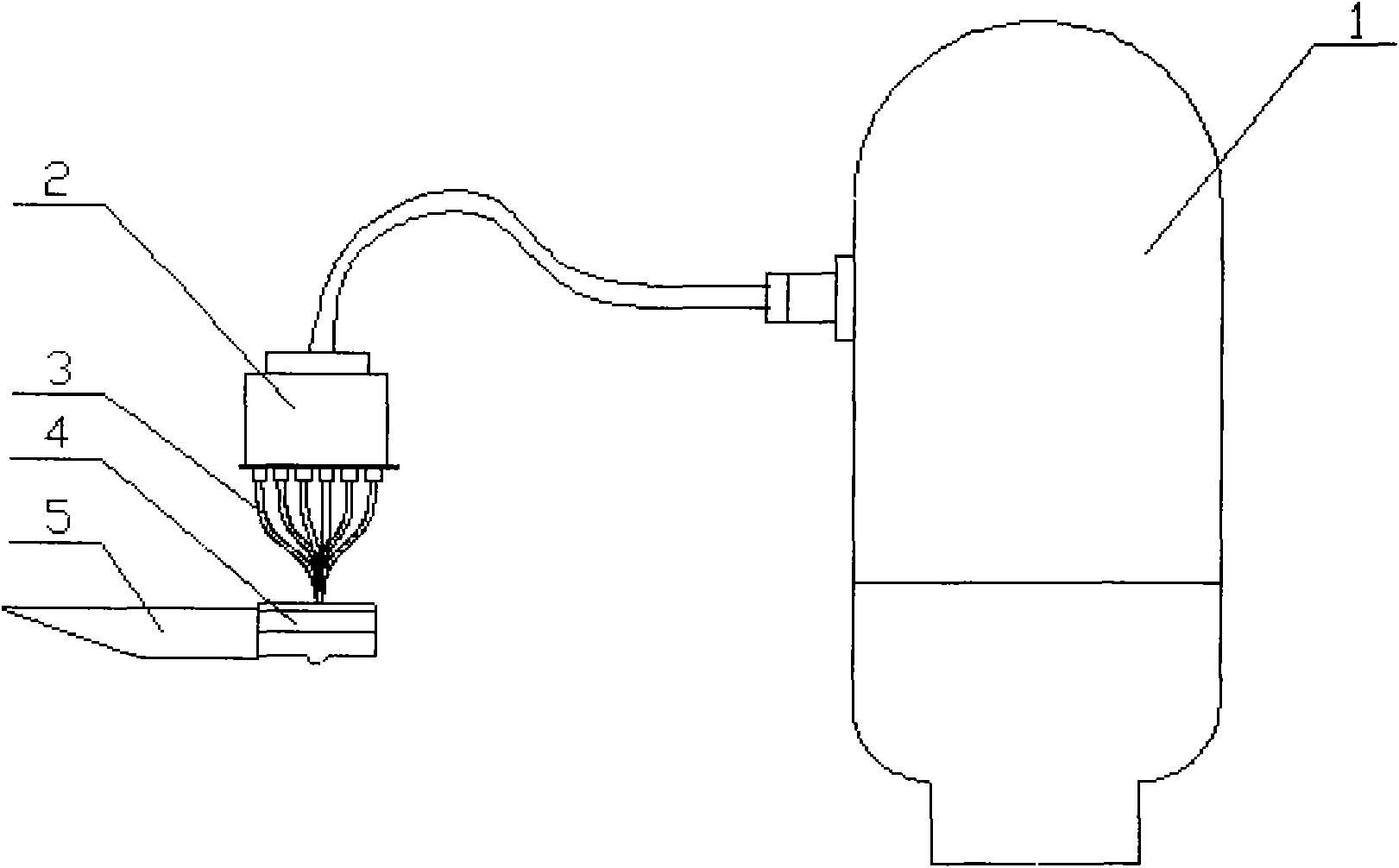

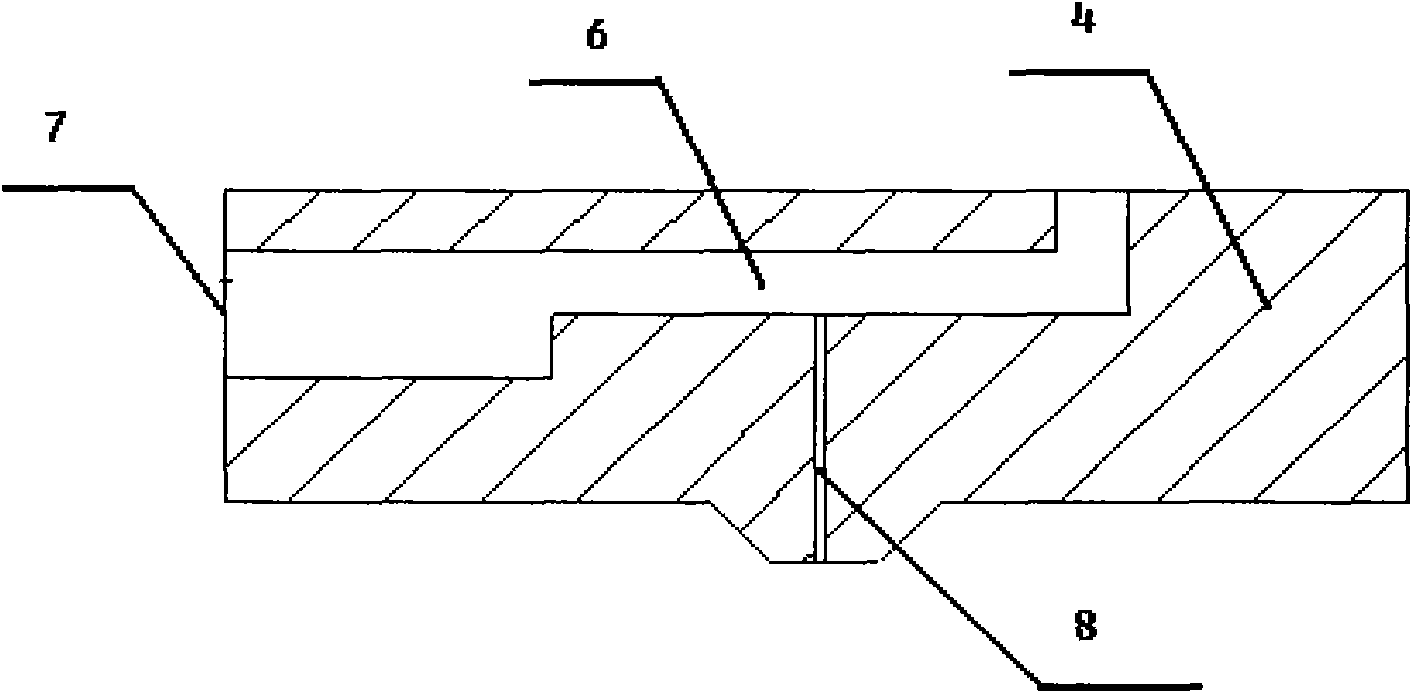

[0014] See attached figure 1 , 2 shown.

[0015] The present invention includes an air source supply device 1 and an air nozzle, the air source supply device 1 and the air nozzle are connected through pipelines, and the air nozzle is a negative pressure suction nozzle device 4 . The negative pressure suction nozzle device 4 is a device provided with a hollow tube 6, one end of the hollow tube 6 communicates with the spray valve 2 and the air source supply device 1 through the multi-way air tube 3, and the other end is the air outlet 7 and communicates with the atmosphere. The middle section of the hollow pipe 6 is provided with an air suction pipeline 8 communicating with the hollow pipe 6 . The diameter of the suction line 8 is smaller than that of the hollow tube 6 . A material cover 5 is provided at the air outlet 7 of the negative pressure suction nozzle device 4 . The air pipe 3 communicates or closes with the air source supply device 1 through the nozzle valve 2 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com