Control device of sewing machine

A control device, sewing machine technology, applied in the direction of sewing machine control device, sewing machine components, motor control, etc., to achieve the effect of improving proficiency and sewing speed, high-speed and high-speed sewing operation, and high-efficiency sewing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

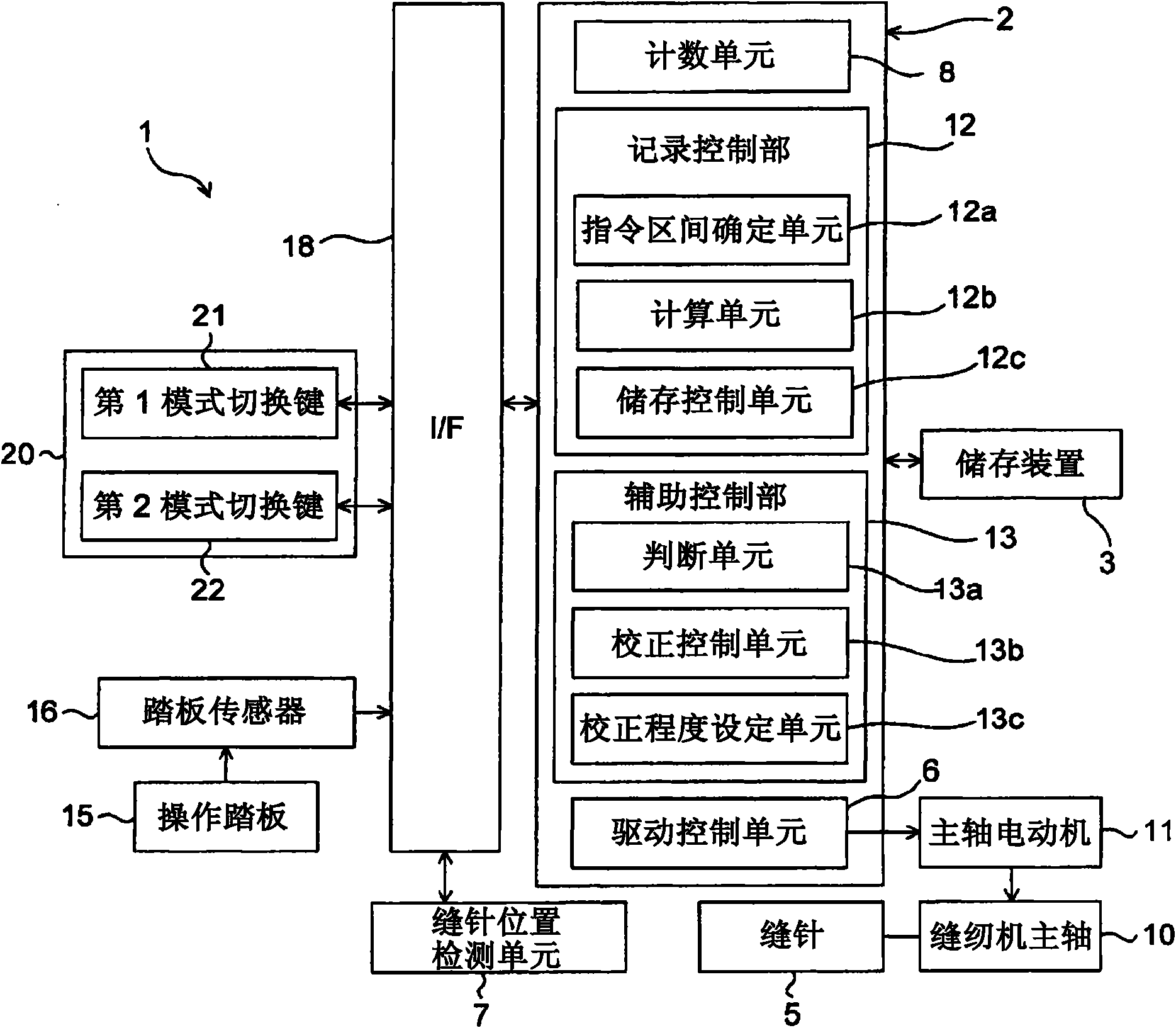

[0033] Below, refer to Figure 1 to Figure 15 , an embodiment of the control device for the sewing machine according to the present invention will be described.

[0034] like figure 1 As shown, the sewing machine 1 according to this embodiment is omitted because the mechanical structure is a known structure, and it has: the sewing machine main shaft 10, which is rotationally driven by the driving of the main shaft motor 11; and the sewing needle 5, which is held on the The lower end of the needle bar (not shown) connected to the main shaft. The sewing machine main shaft 10 is rotated by rotationally driving the main shaft motor 11, and the sewing needle 5 is moved up and down via a needle bar connected thereto.

[0035] A needle position detection unit 7 is provided near the needle bar, which detects that the vertically moving needle 5 reaches a predetermined vertical movement position, and outputs a needle position signal. The needle position detection unit 7 detects the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com