Temperature self-compensating double grating symmetrical push-pull type fiber grating vibrating sensor

A vibration sensor, fiber grating technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of difficult to meet high-quality measurement of low-frequency vibration signals, no temperature self-compensation, low sensitivity, etc. Stability and adaptability to the environment, elimination of temperature drift, effect of large dynamic range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

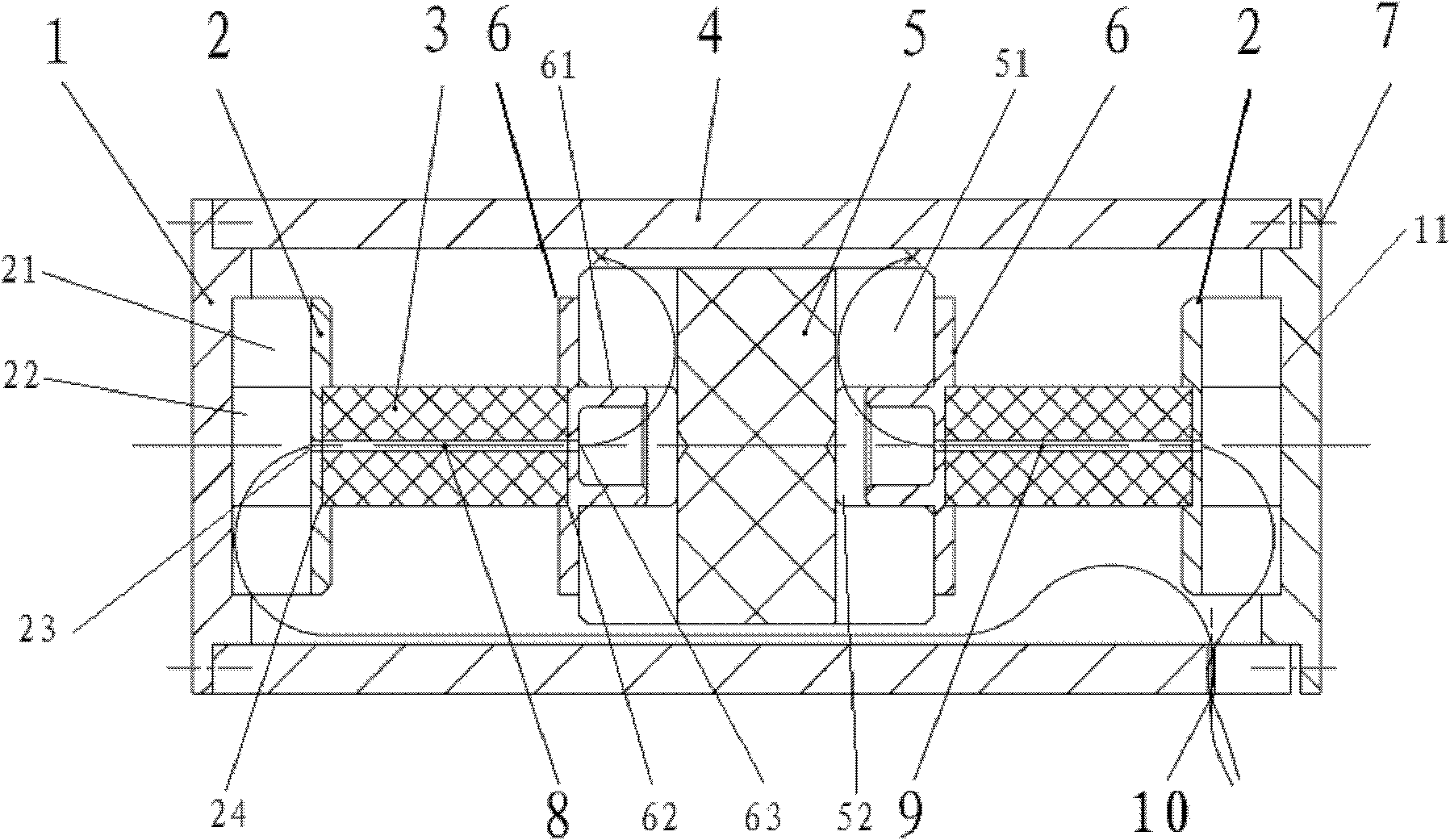

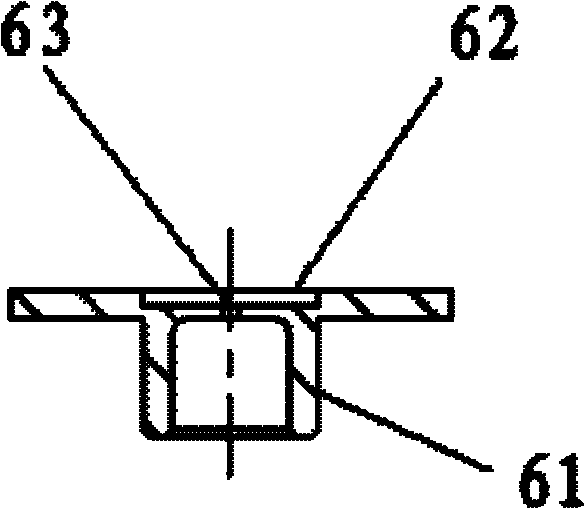

[0026] Such as figure 1 As shown, the present invention consists of a housing, two elastic blocks 3, a mass block 5, a first sensing fiber Bragg grating 8, a second sensing fiber Bragg grating 9, two connecting seats 6 and two supporting bases 2 . The mass block 5 is located between two symmetrical solid elastic body blocks 3, and the two ends of the mass block 5 are pasted with connecting seats 6 respectively. The base 2 is butted and bonded to form a symmetrical push-pull structure, and the two sensing fiber gratings are respectively packaged in the elastomer block 3 to form a dual fiber grating sensor. A modular assembly structure is adopted, and the mass block 5, the elastic body block 3, the first sensing fiber Bragg grating 8, the second sensing fiber Bragg grating 9, the connecting seat 6 and the supporting base 2 form a sensing probe placed inside the housing.

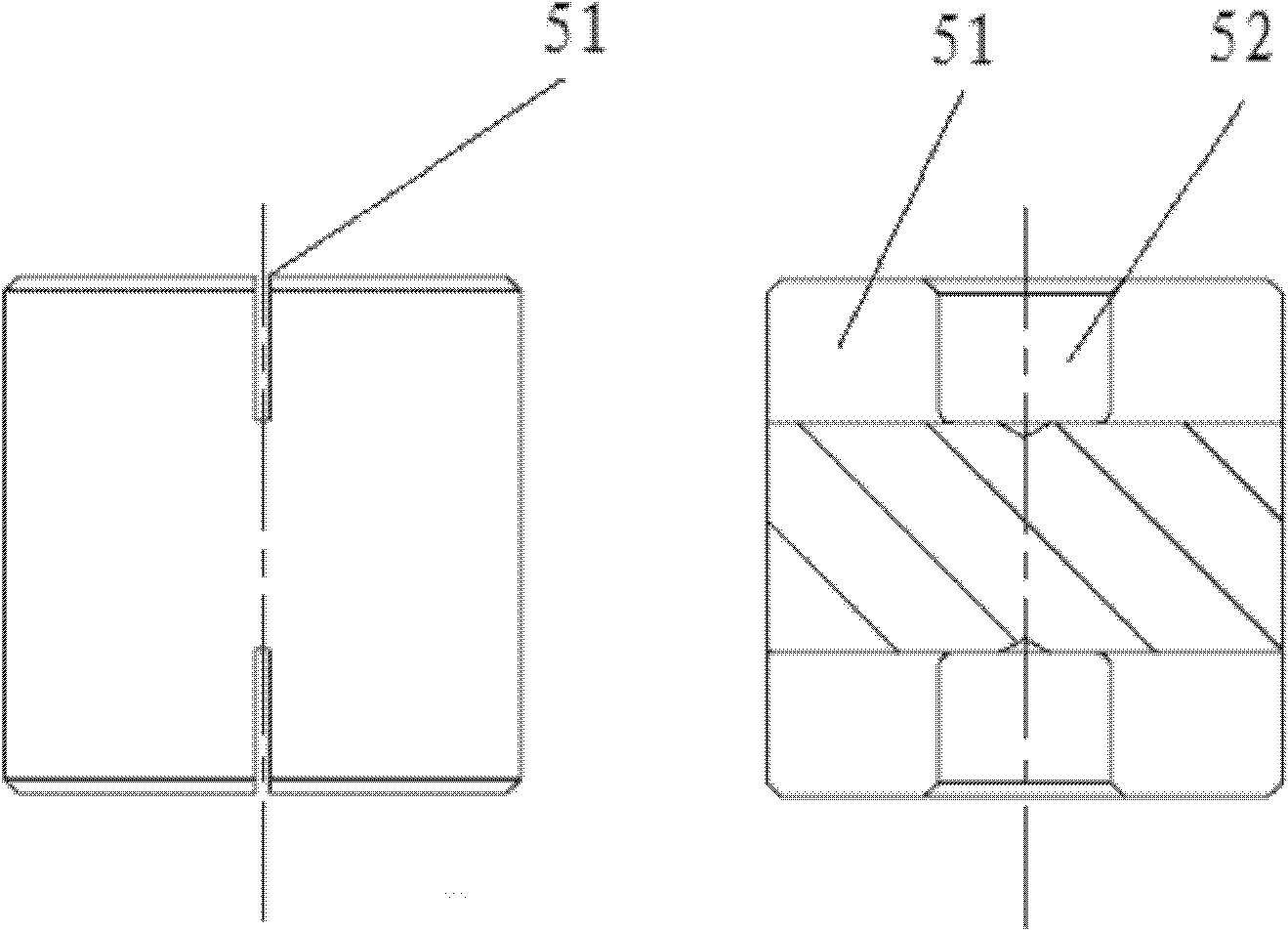

[0027] Such as figure 2 As shown, the mass block 5 is a copper cylinder, and there are first cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com