Shaft coupling

A coupling and shaft sleeve technology, applied in the field of hydraulic machinery, can solve problems such as troubles and increased costs, and achieve the effects of cost saving, convenient installation, and good shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

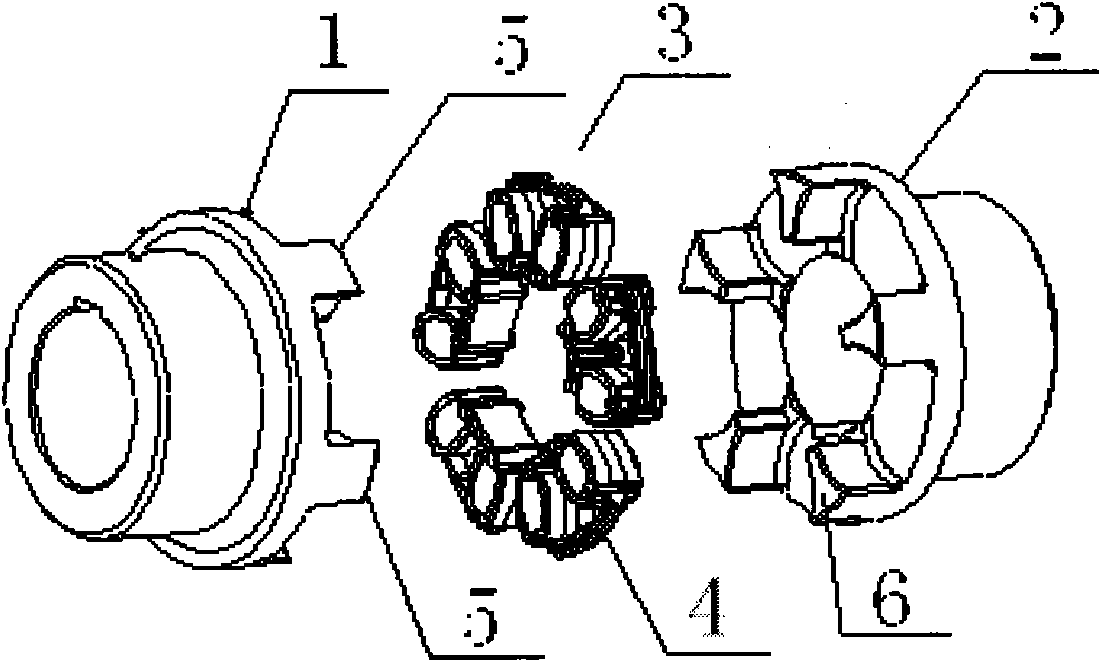

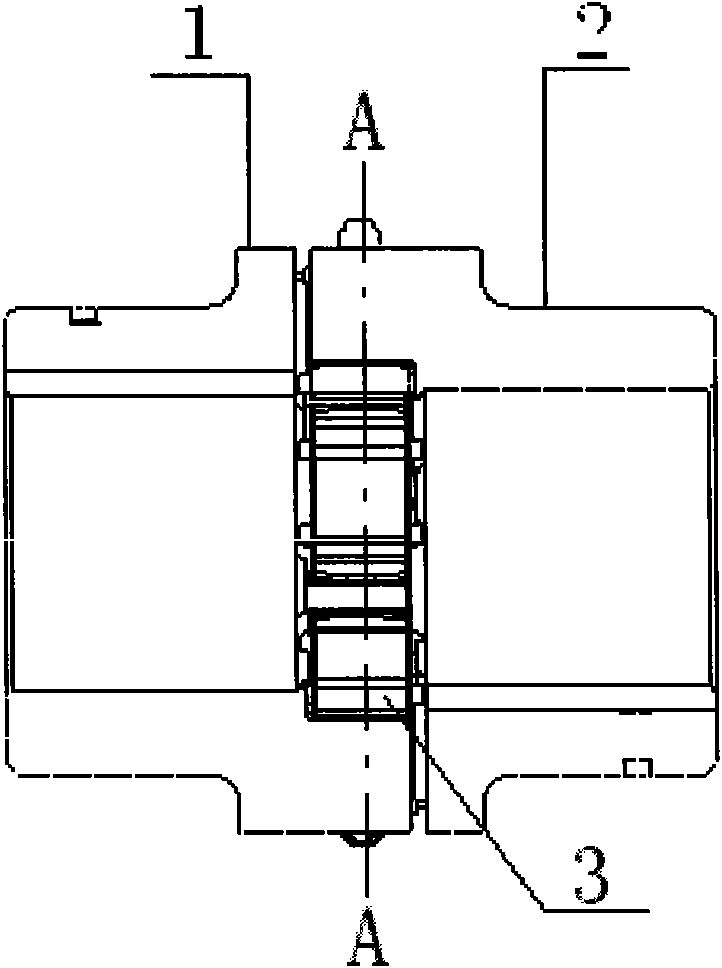

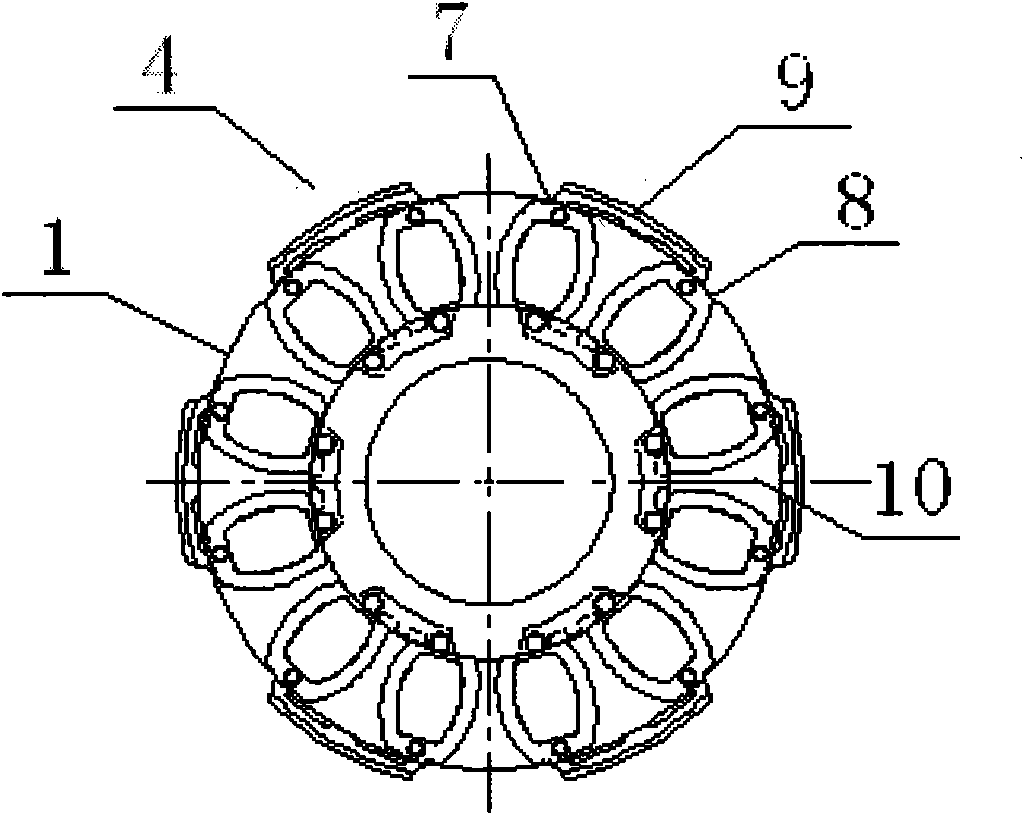

[0015] Such as figure 1 , figure 2 , image 3 with Figure 4 A shaft coupling shown includes a first shaft sleeve 1, a second shaft sleeve 2 and an elastic body 3 installed between the first shaft sleeve 1 and the second shaft sleeve 2, and the elastic body 3 includes 6 elastic elements 4. The elastic element 4 includes a first tooth 7 and a second tooth 8, the first tooth 7 and the second tooth 8 are connected by a rib 9, and a hole is formed between the first tooth 7, the second tooth 8 and the rib 9 10. The hole 10 is matched with the second tooth 6 of the second bushing 2 . The elastic element 4 is detachably installed between two adjacent first teeth 5 of the first bushing 1, and the second bushing 2 is connected to the first bushing 1 and the elastic Body 3 is combined to form a whole.

[0016] When the present invention is in use,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com