On-line calculation and self-adaptation nonlinear prediction control method of catalytic cracking reaction depth

A non-linear prediction and reaction depth technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem that the real-time performance cannot meet the advanced control of the riser, and the catalyst circulation cannot meet the real-time performance of production monitoring and control. Requirements, accuracy is difficult to guarantee and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

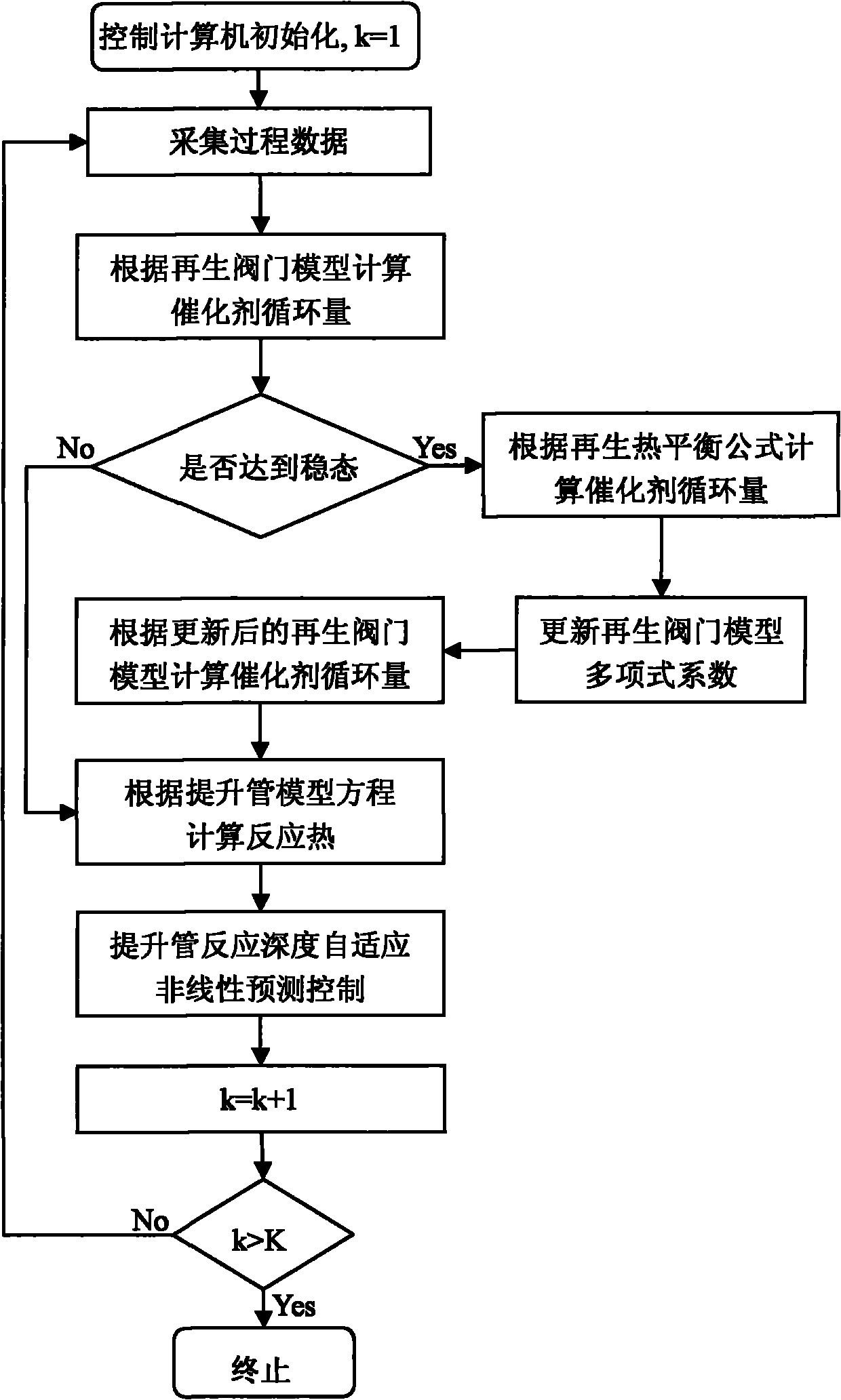

[0078] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

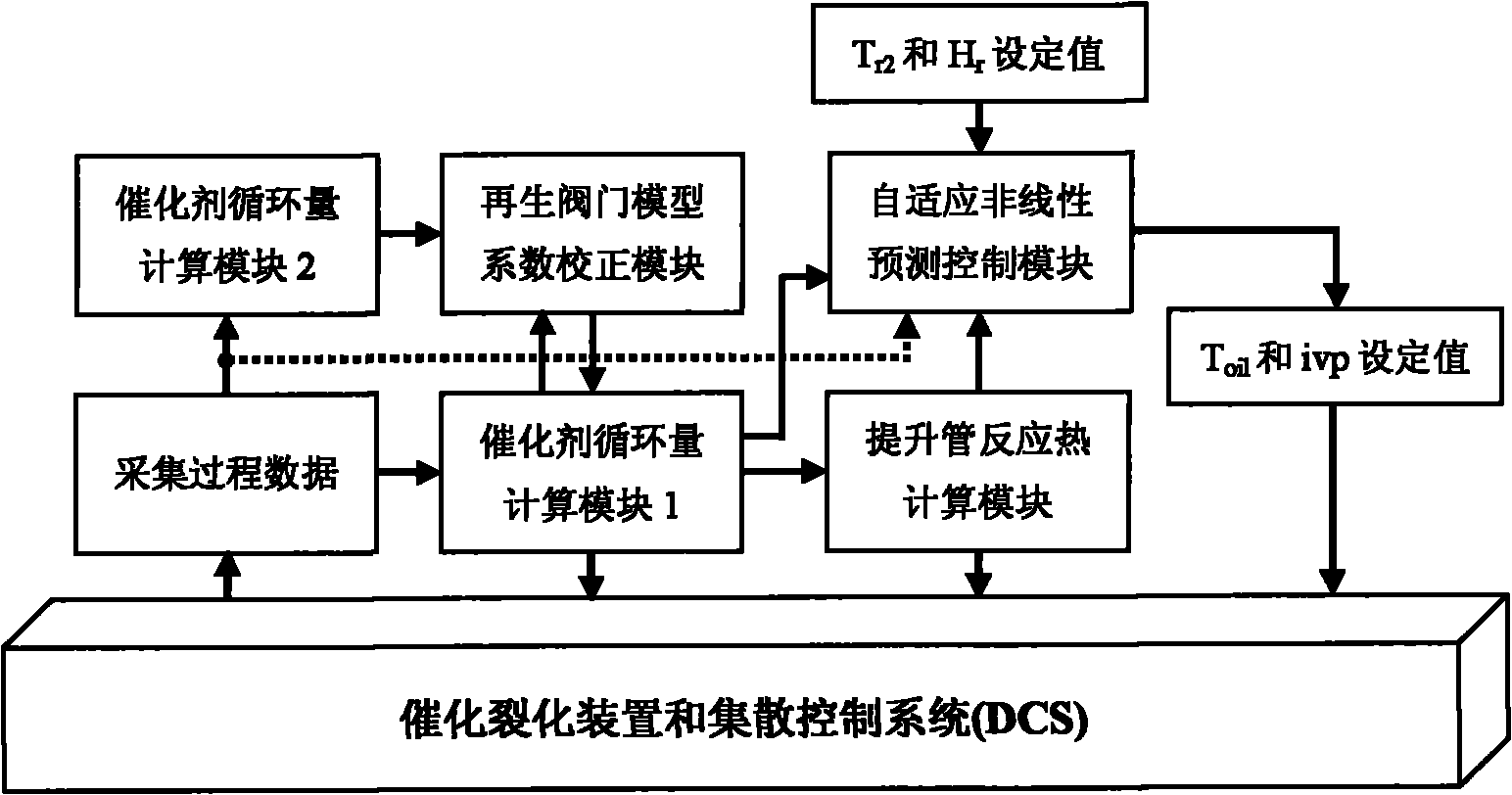

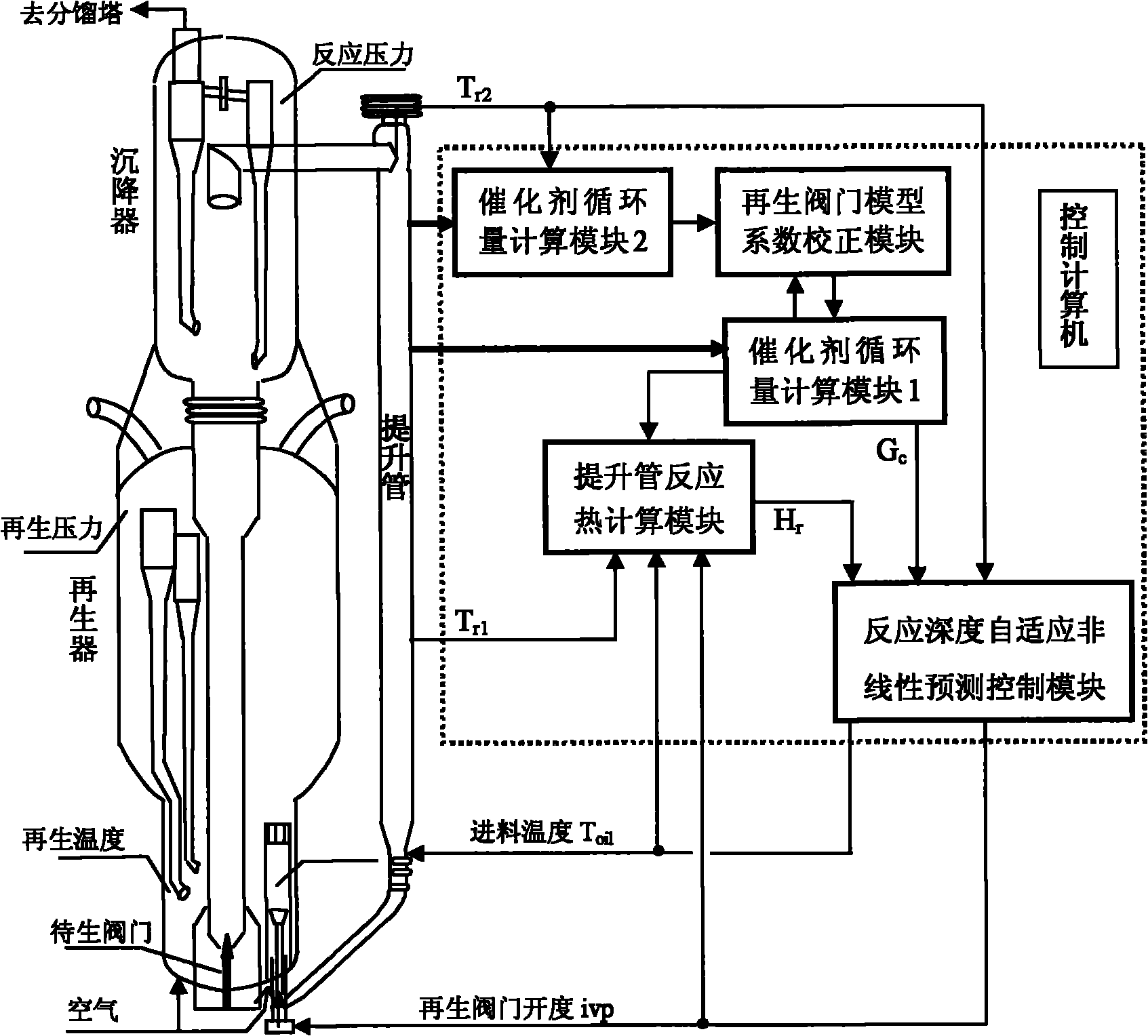

[0079] The present invention is characterized in that the parameters of the regeneration valve model are corrected online by using the heat balance calculation results that are relatively accurate but have a large time lag, thereby obtaining an adaptive regeneration valve model that can adapt to changes in working conditions and meet the relative requirements for catalyst circulation estimation. Accuracy and real-time dual requirements. Finally, based on the dynamic mathematical model of the riser, the online calculation of the reaction heat is completed; when establishing the mathematical model of the riser for dynamic control, according to the characteristics of the rege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com