Multifrequency control stage for improved dampening of excitation factors

A control stage, entry arc technology, applied in the field of steam turbines, which can solve problems such as lack of uniformity of circumferential steam distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

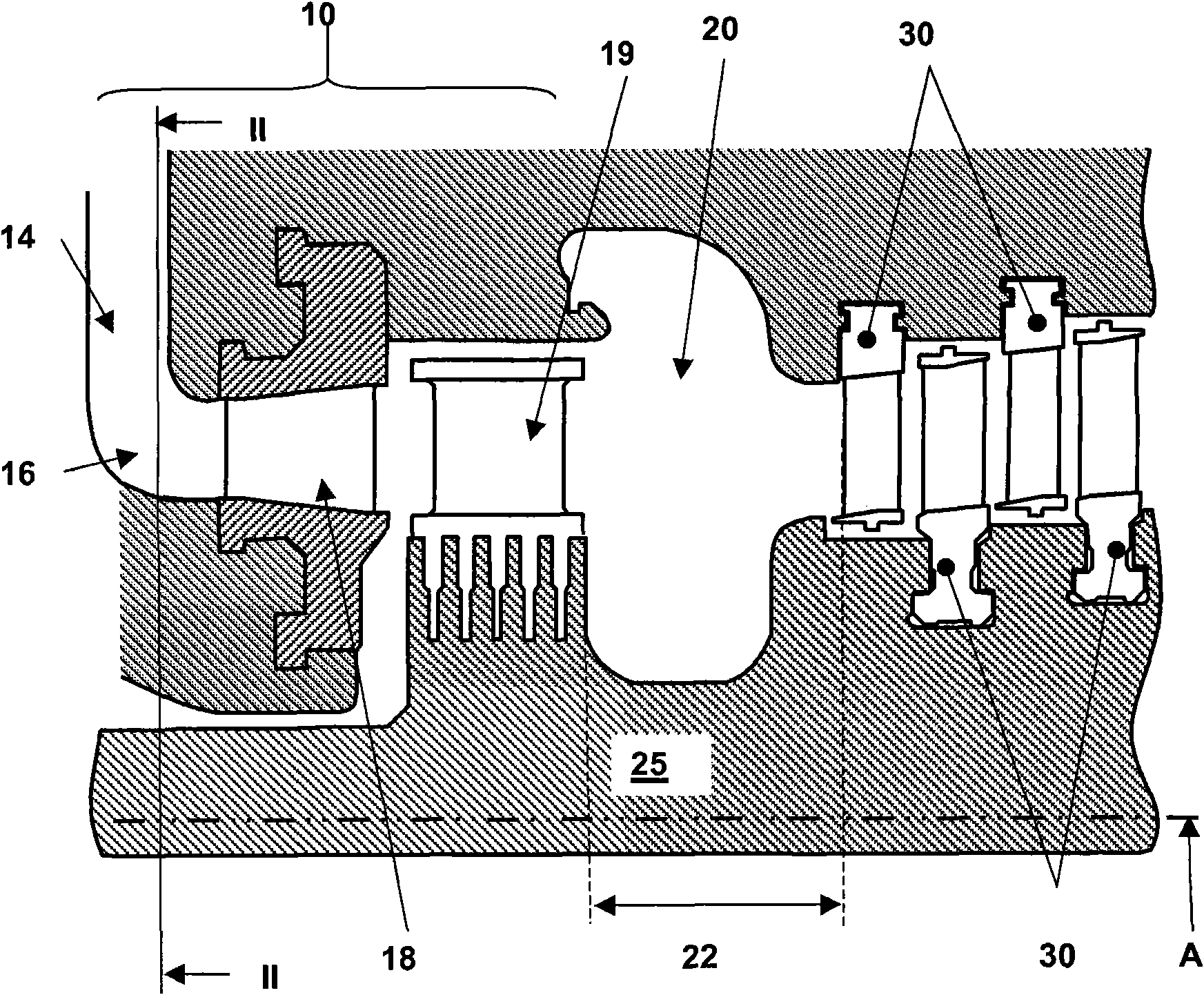

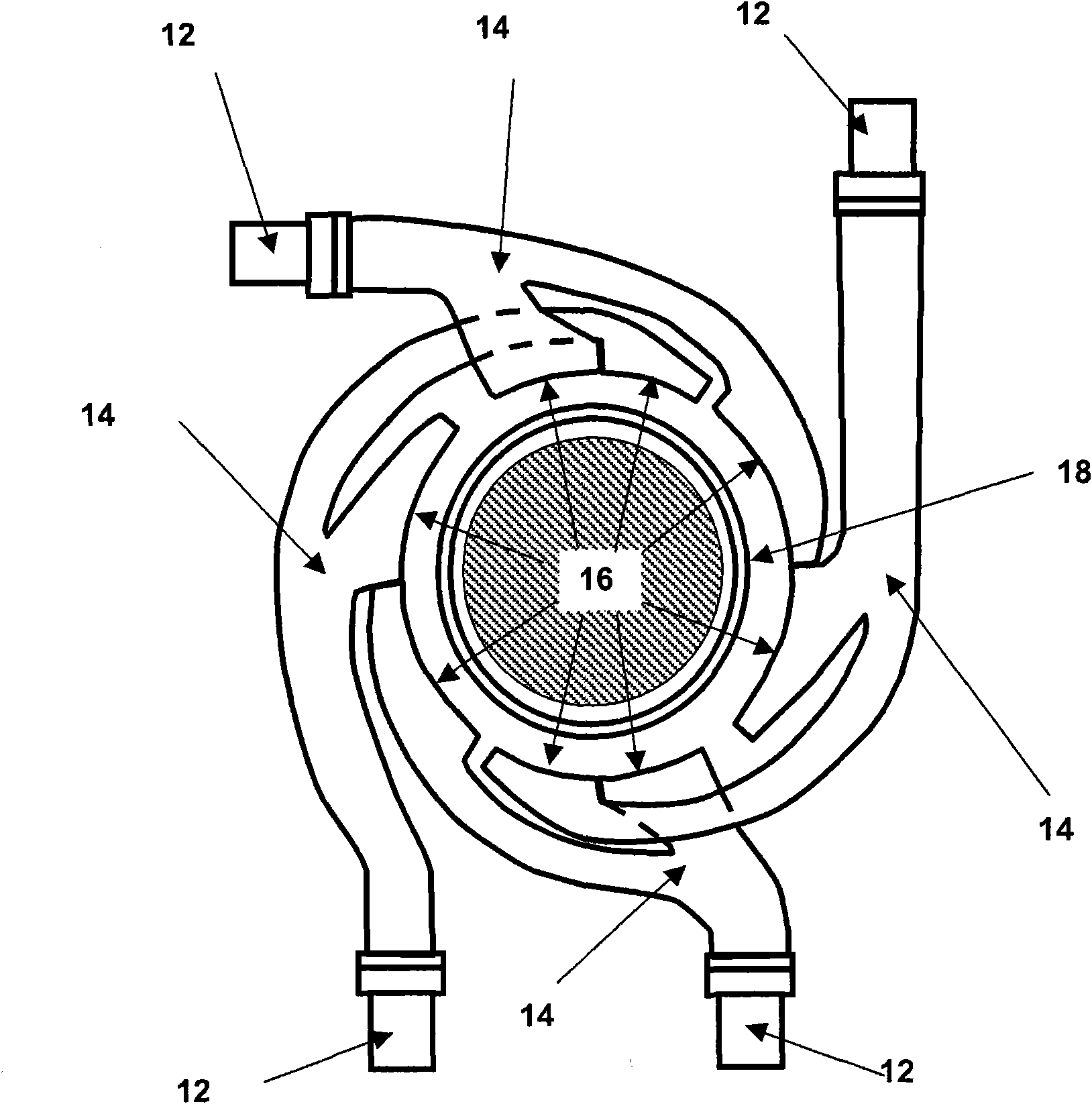

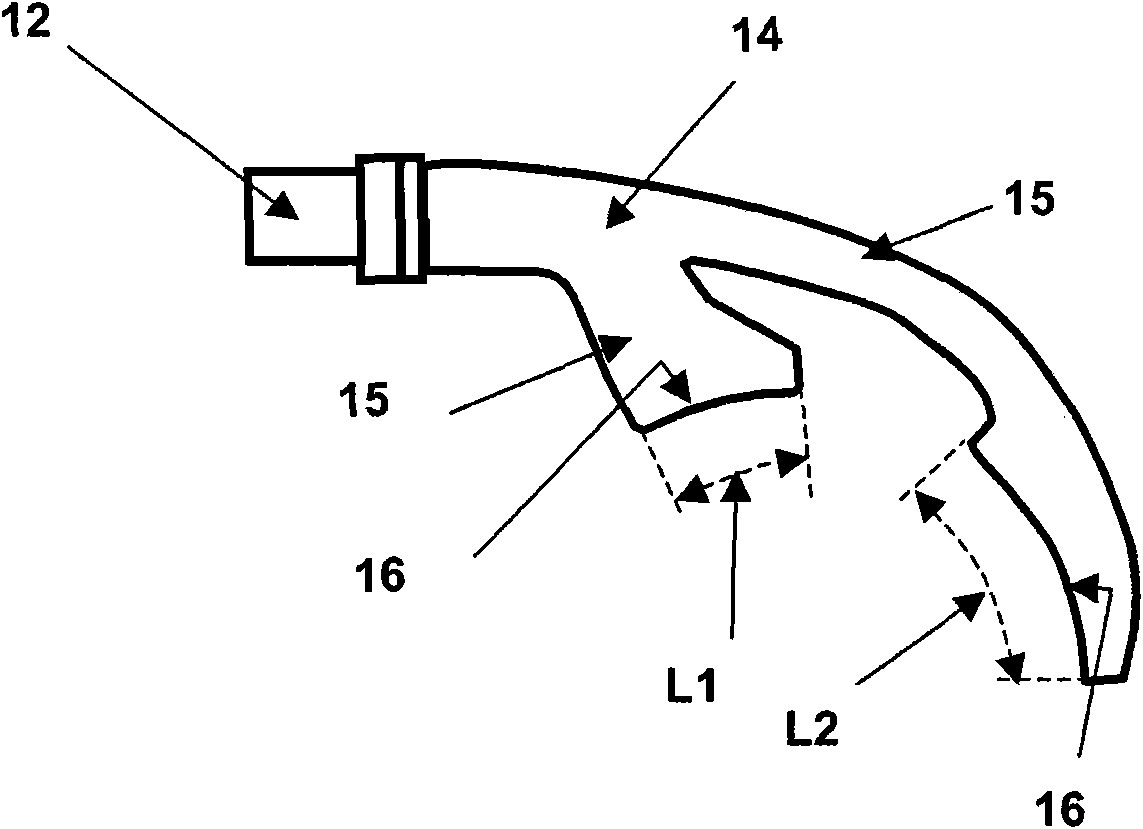

[0018] Preferred embodiments of the invention will now be described with reference to the drawings, wherein like reference numerals are used to refer to like elements throughout. In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It may be obvious, however, that the invention may be practiced without these specific details. Throughout this specification, a circumferential reference refers to an arc of constant vertical distance to the longitudinal axis of the turbine.

[0019] figure 1 A side view of a steam turbine is shown with a control stage 10 configured with a partial arc entry system. The control stage 10 includes stage valves 12 such as figure 2 As shown, it is used to control the load of the steam turbine. Downstream of the connection stage valve 12 is a nozzle chamber 14 . The downstream portion of the nozzle chamber 14 includes an inlet arc 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com