Noncontact-type test method of early-period thermal expansion coefficient of concrete dam and equipment thereof

A thermal expansion coefficient, non-contact technology, applied in the thermal expansion coefficient of materials, measuring devices, instruments, etc., can solve the problems of difficult to ensure the accuracy of the results, difficult to continuously test the thermal expansion coefficient, and affect the early hydration of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, the test method of non-contact dam concrete early thermal expansion coefficient, the test device that adopts is as Figure 4 .

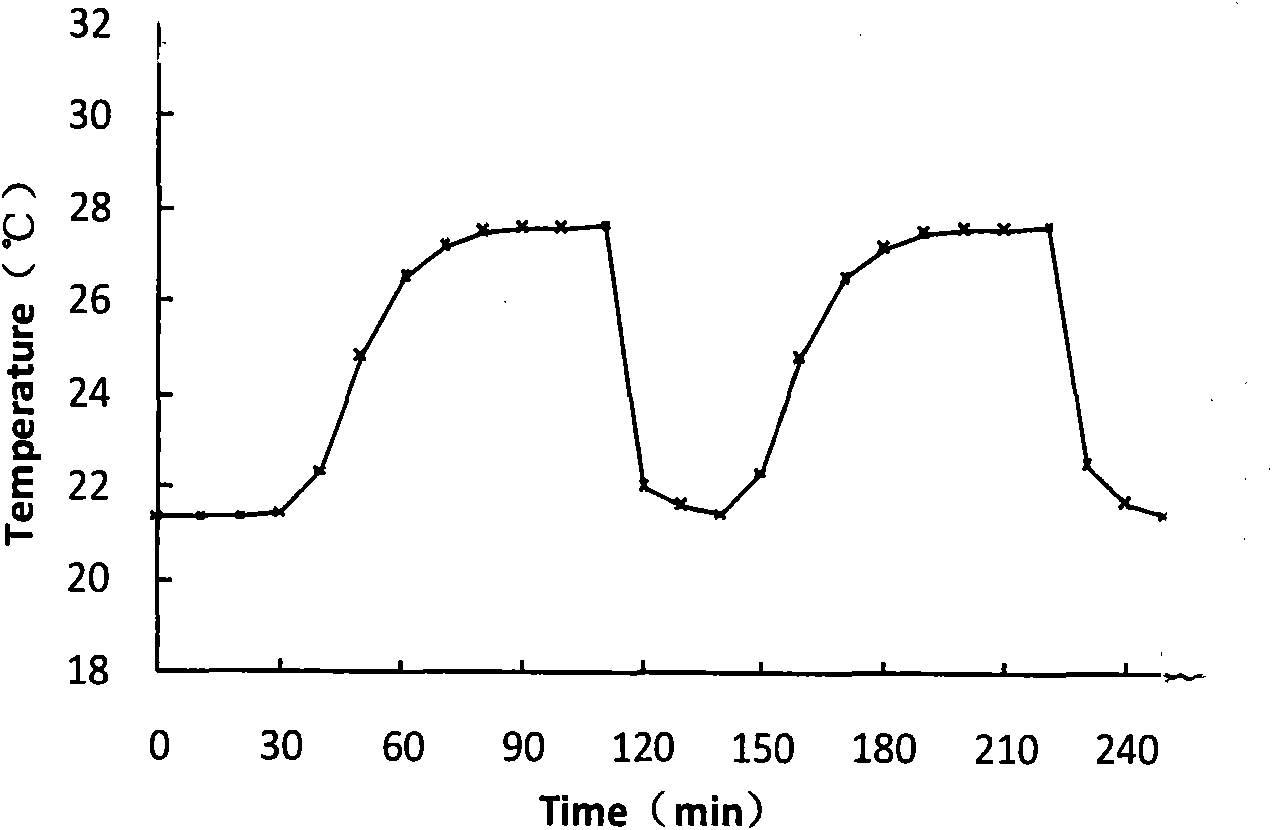

[0036] The freshly mixed dam concrete is directly loaded into the φ150mm×300mm cylindrical tinplate barrel 2 with a polytetrafluoroethylene plate at the bottom (the second-grade concrete is directly loaded, and the fully-graded dam concrete is loaded after wet screening); the top of the concrete is placed The metal test tip is immediately put into constant temperature water bath 3 for curing. Both the constant temperature water bath 3 and the concrete 1 are provided with a thermometer 4 . The test piece in the tinplate bucket—the top of the freshly mixed dam concrete 1 is covered with PVC film, and the flat and smooth metal test end (iron) is pre-embedded. During the test, the condensation of water vapor at the end is avoided, which will affect the test of the laser displacement sensor. Stability: After testing and debugging, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com