Method for aging of low-voltage, high-current and non-isolated DC-DC power supply

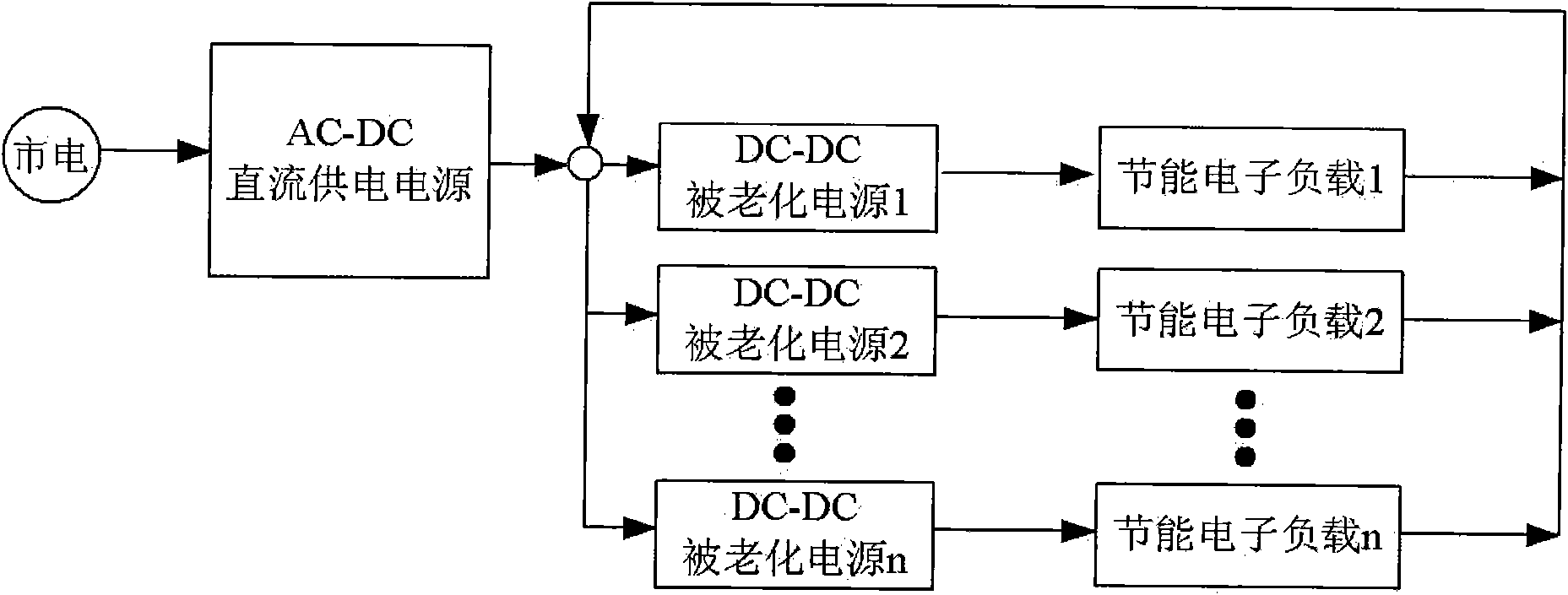

A non-isolated, power aging technology, applied in power supply testing and other directions, can solve the problems of thermal design difficulties, low efficiency, and large heat generation of energy-saving electronic loads, and achieve the effect of filling the gap in the industry and achieving good energy-saving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

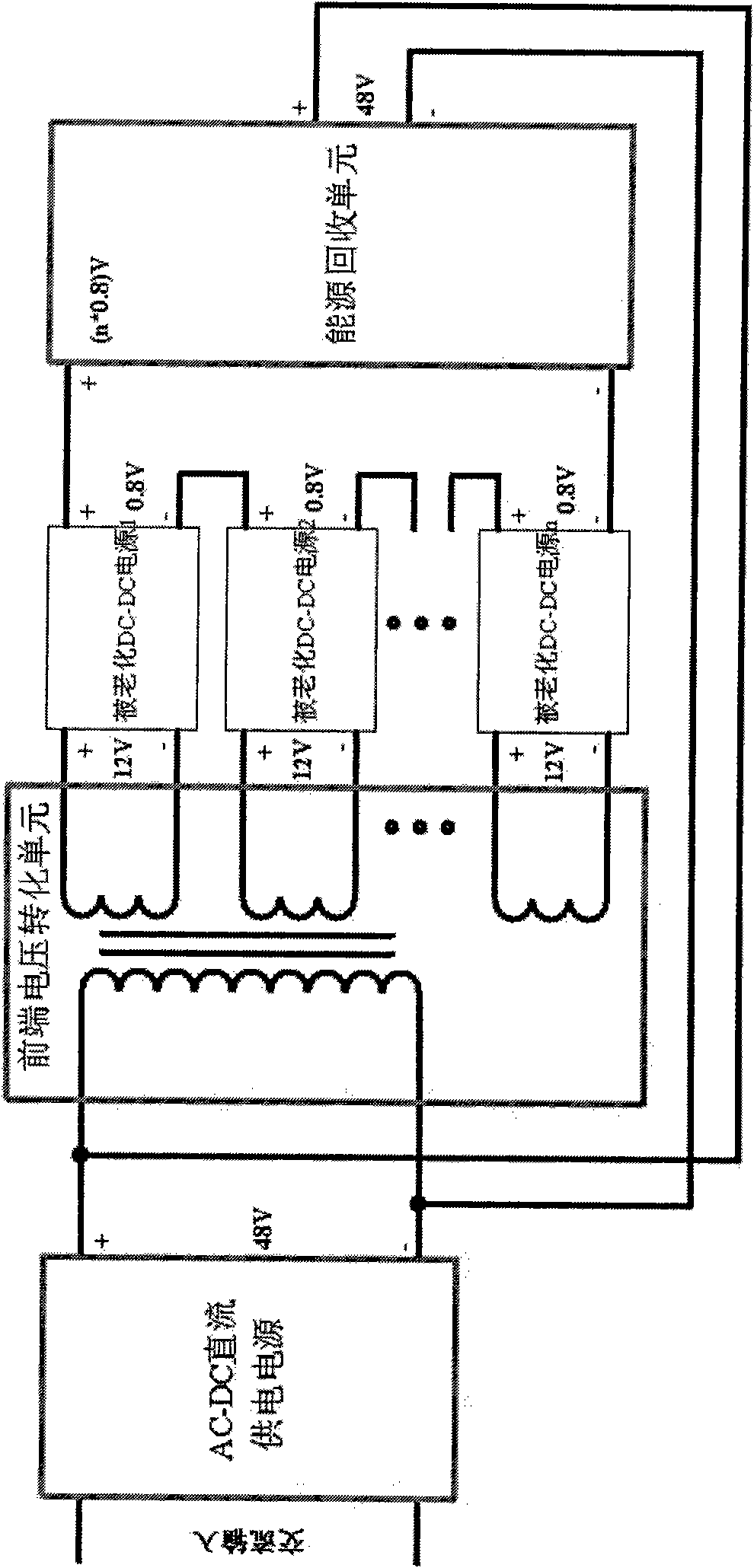

[0016] See image 3 Shown: the low-voltage high-current non-isolated DC-DC power supply aging method of the present invention is to set the front-end voltage conversion unit at the output end of the AC-DC DC power supply, and convert the DC voltage of 48V output by the AC-DC DC power supply to Multiple output voltages that are electrically isolated from it, the multiple output voltages are respectively connected to the input terminals of multiple aged DC-DC power supplies, and the voltage obtained after connecting the output voltages of the aged DC-DC power supplies in series is converted to 48V by the energy recovery unit output, and connected to the input of the front-end voltage conversion unit.

[0017] See Figure 4 Shown: the front-end voltage conversion unit converts the DC 48V voltage output by the AC-DC DC power supply into multiple DC 12V voltage outputs that are electrically isolated from it. This circuit adopts a double-terminal forward topology, and the output v...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap