Optical polyester film and preparation method thereof

An optical polyester film and film technology, which is applied in the field of polyester film, can solve the problems of easy scratching of the film, easy generation of bumps and adhesion during storage, and achieve the goals of ensuring winding performance, reducing haze, and high light transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

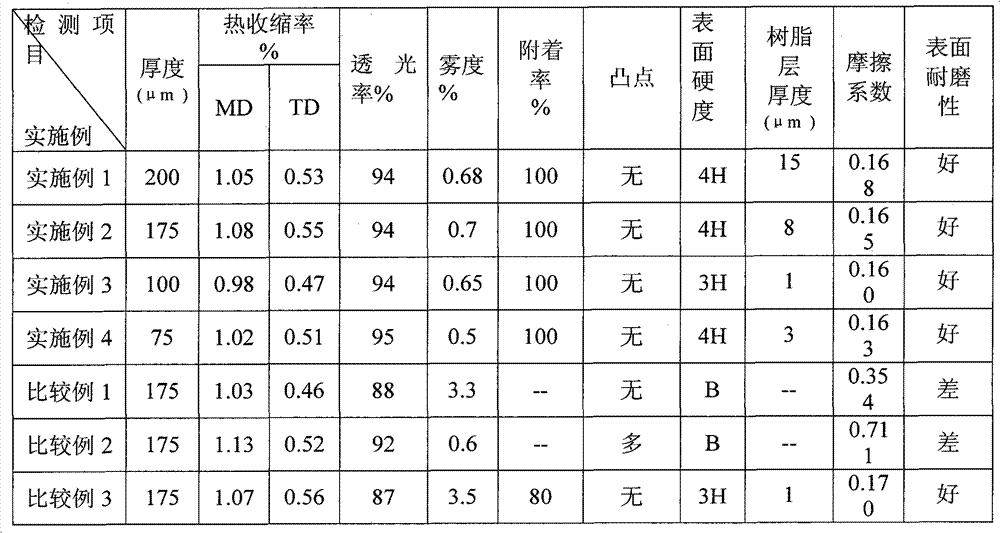

Examples

Embodiment 1

[0038] 1. Preparation of cross-linkable resin coating liquid:

[0039] Acrylic resin with curing agent

[0040] Seika-beam EXF-01L (NS) (manufactured by Dainichi Seika Co., Ltd.), solid concentration 100%.

[0041] 2 Preparation of polyester film

[0042] The polyester chips are crystallized and dried at 170°C; the dried chips are melted and extruded through an extruder at a temperature of 260°C, and the polyester melt flows out through a die to a casting roller at 30°C and is rapidly cooled to form a thick sheet; The sheet enters the longitudinal stretching machine, after being preheated by the preheating roller and heated by the infrared heater, it is stretched 3.1 times longitudinally at a temperature higher than the glass transition temperature of the polyester, and then cooled rapidly; the longitudinally drawn sheet enters the transverse stretching machine, After being preheated at 95°C in the preheating zone, it is stretched 3.2 times in the transverse direction, heat-...

Embodiment 2

[0044] 1. Preparation of cross-linkable resin coating liquid:

[0045] Acrylic resin containing curing agent: SU-683 (Dizhan International), solid concentration 80%.

[0046] 2. Film preparation:

[0047] The polyester chips are crystallized and dried at 165°C; the dried chips are melted and extruded through an extruder at a temperature of 260°C, and the polyester melt flows out through a die to a casting roller at 25°C and is rapidly cooled to form a thick sheet; The sheet enters the longitudinal stretching machine, after being preheated by the preheating roller and heated by the infrared heater, it is stretched 3.0 times longitudinally at a temperature higher than the glass transition temperature of the polyester, and then cooled rapidly; then coated with polyacrylate resin type adhesive The bottom layer of the mixture, the longitudinal stretching sheet enters the transverse stretching machine, after being preheated at 100°C in the preheating zone, it is stretched 3.3 times...

Embodiment 3

[0049] 1. Preparation of cross-linkable resin coating liquid:

[0050] Acrylic resin with curing agent

[0051] LC-5537-30 (manufactured by Changxing Chemical Industry: solid content 30%) 33 parts by weight

[0052] Butanone 67 parts by weight

[0053] In a container with a stirrer, add acrylic resin LC-5537-30 (manufactured by Changxing Chemical Industry: 30% solid content) and butanone containing a curing agent according to the above ratio, stir and mix evenly to obtain a coating with a solid concentration of 10%. cloth liquid.

[0054] 2. Film preparation:

[0055] The polyester chips are crystallized and dried at 150°C; the dried chips are melted and extruded through an extruder at a temperature of 300°C, and the polyester melt flows out through a die to a casting roll at 15°C and is rapidly cooled to form a thick sheet; The thick sheet enters the longitudinal stretching machine, after being preheated by the preheating roller and heated by the infrared heater, it is st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com