Clamping and protecting device for one-sided processing

A protection device, single-sided technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to solve problems such as safe clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

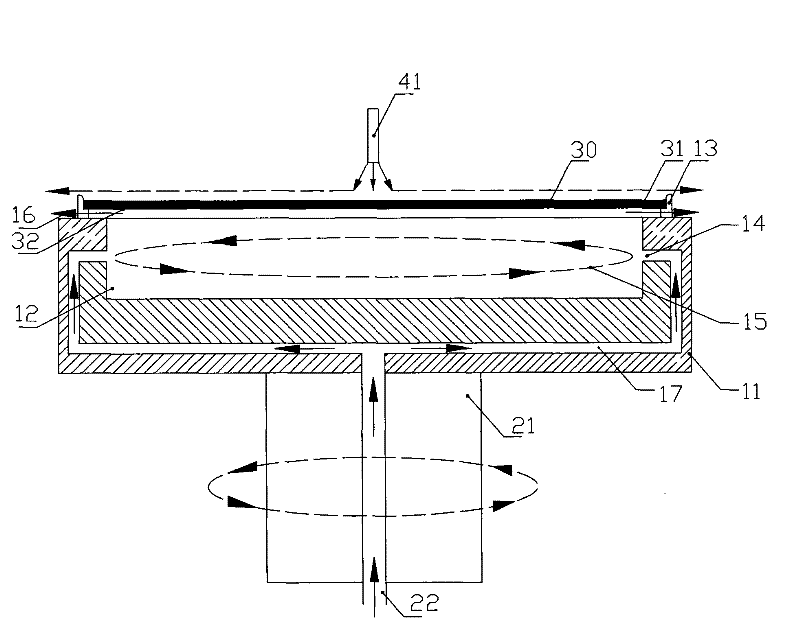

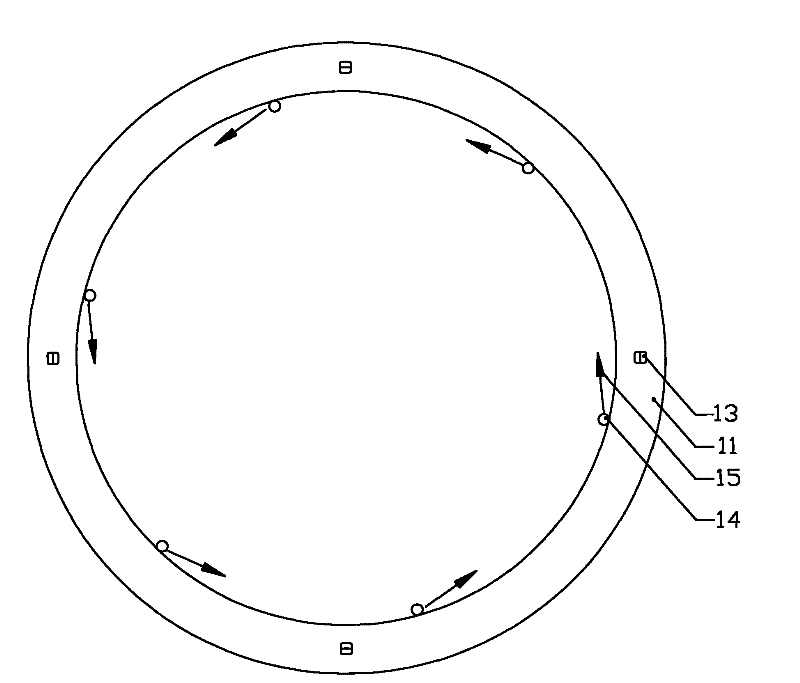

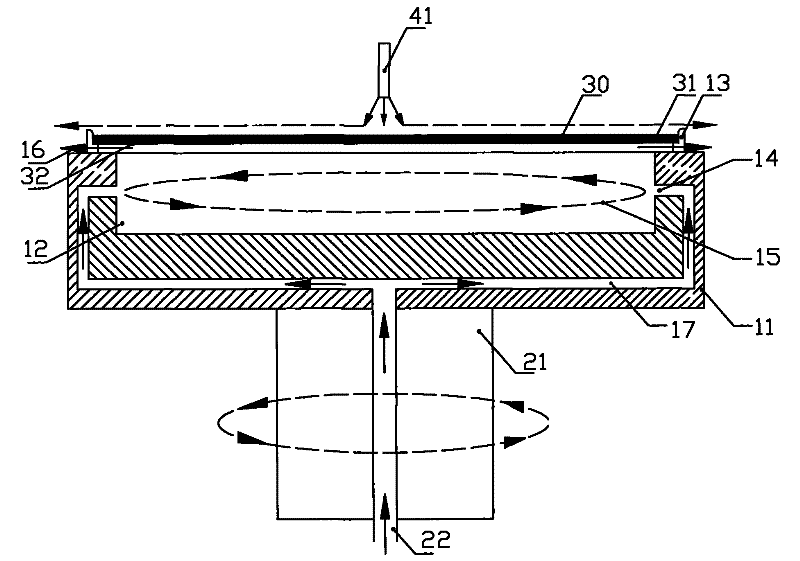

[0024] Such as figure 1 As shown, the entire device of the present invention includes a rotating disk 11 and a rotating shaft 21. The rotating disk 11 is located above the entire device for placing silicon wafers 30 or discs. The hollow rotating shaft 21 is connected to the bottom of the rotating disk 11. Driven by the motor, the rotating shaft 21 can drive the rotating disk 11 to rotate at a speed of 100-5000 revolutions per minute. There is a cylindrical groove 12 in the center of the upper surface of the rotating disk 11, and the supporting frame 13 is positioned at the peripheral edge of the upper surface of the rotating disk 11, and the silicon wafer 30 is placed on the supporting frame 13, so that the silicon wafer 30 and the rotating disk 11 are both There is a gap between the edges, and the support frame 13 can help guide and hold the silicon wafer 30 in the correct position. The gas nozzle 14 is located on the side wall of the groove 12, the axial direction of the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com