Corn ear uniform mechanism of peeler of corn harvester

A corn harvester and corn ear technology, which is applied to harvesters, agricultural machinery and implements, threshing equipment, etc., can solve the problem of not having a corn harvester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

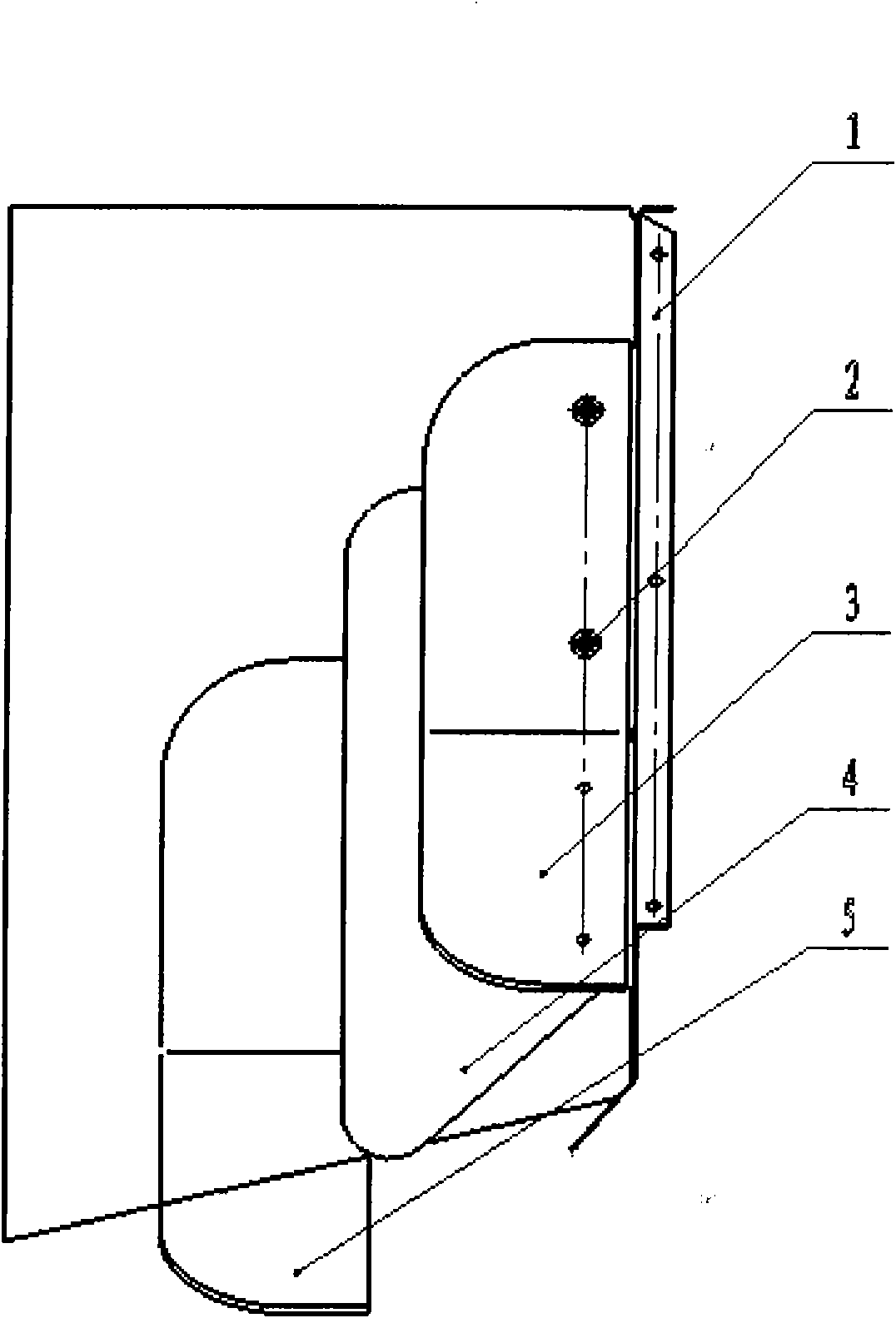

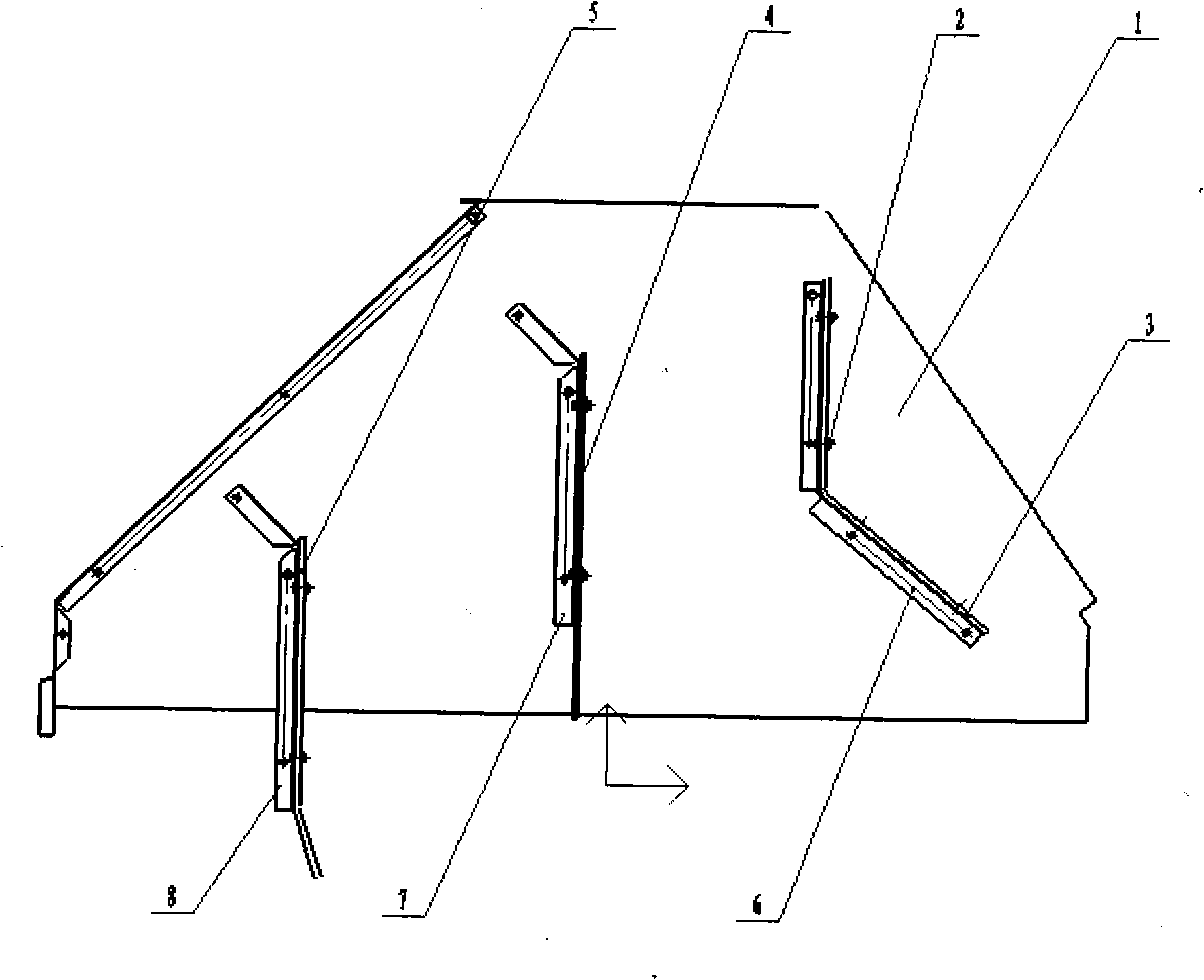

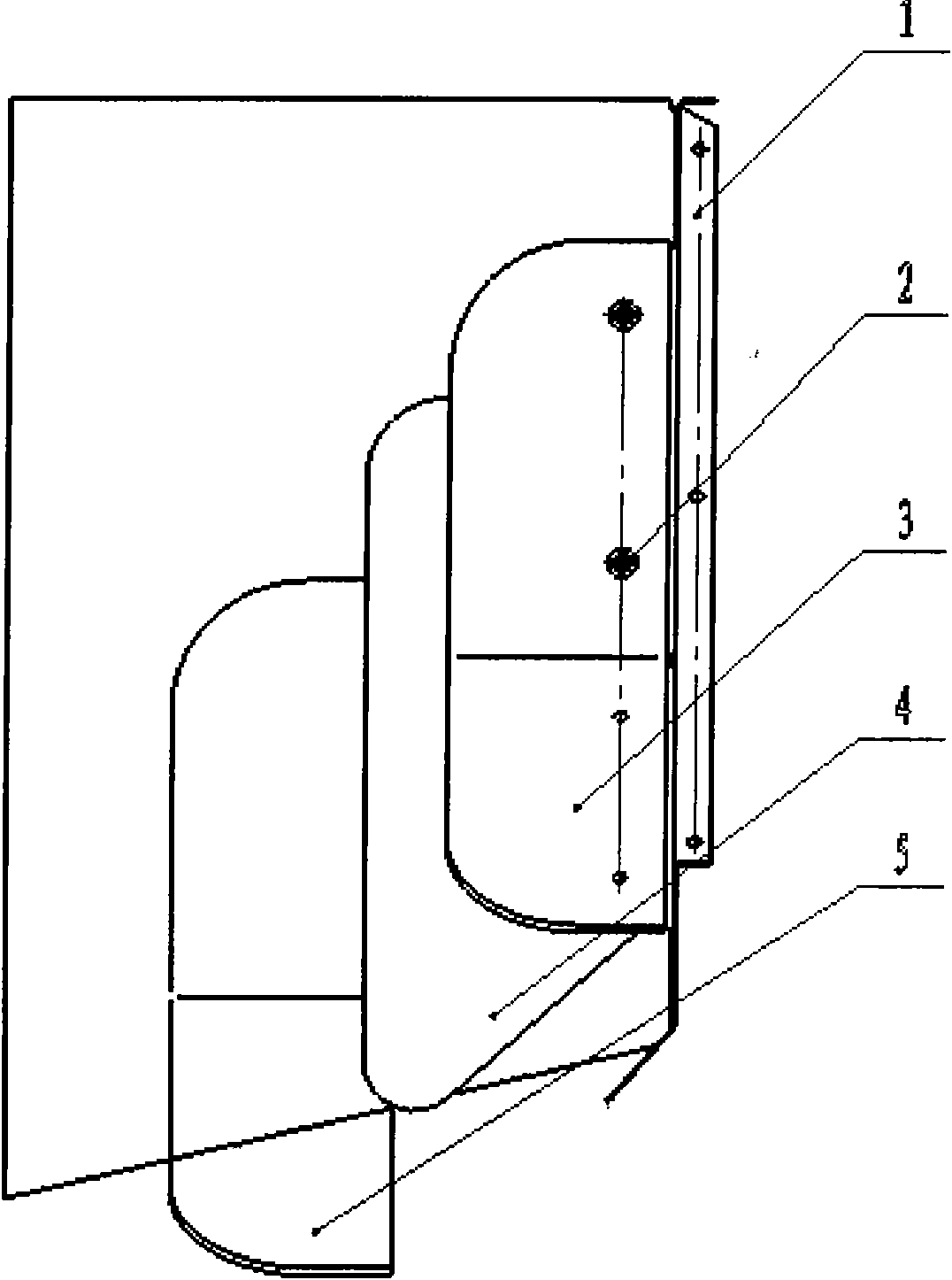

[0019] Embodiment 1. Corn ear distribution mechanism of corn harvester peeling machine

[0020] The corn ear distribution mechanism of this corn harvester peeling machine of this example is the mechanism for dividing the ears of corn when the corn ears enter the peeling machine. It is an integral part of the corn harvester. The overall harvesting efficiency of the harvester. The corn ear distribution mechanism of the peeling machine is composed of three corn ear distribution baffles arranged or installed on the peeler frame, specifically the distribution mechanism is arranged on the grain receiving trough of the corn ear elevator In the above, due to the function of the three corn ear distribution baffles, the corn ears thrown from the corn ear elevator are evenly distributed to the four pairs of peeling rollers of the peeling machine for peeling operation, and the four pairs of peeling rollers of the peeling machine are fully utilized. The peeling effect of the roller, there...

Embodiment 2

[0021] Embodiment 2. Corn ear distribution mechanism of corn harvester peeling machine

[0022] The general structure of the corn ear distribution mechanism of the corn harvester peeling machine of this example can be used Figure 1 ~ Figure 2 etc. jointly show that the corn ear distribution mechanism of the corn harvester peeling machine of this example is different from the corn ear distribution mechanism of the corn harvester peeling machine of embodiment one: 1. if the n pairs of the peeling machine of this example Three pairs of peeling rollers n are selected, so two (n-1) should be selected correspondingly for the splitting baffles of the splitting mechanism of this example. 2. If the number of pairs of peeling rollers n is selected as three pairs, the width of the first baffle should be 1 / 3 the length of the peeling rollers (that is, the length of 1 / n peeling rollers) and the width of the second baffle should be 2 / 3 the length of the peeling rollers. 3. the first baffl...

Embodiment 3

[0023] Embodiment 3. Corn ear distribution mechanism of corn harvester peeling machine

[0024] The general structure of the corn ear distribution mechanism of the corn harvester peeling machine of this example can be used Figure 1 ~ Figure 2 etc. jointly show that the corn ear distribution mechanism of the corn harvester peeling machine of this example is different from the corn ear distribution mechanism of the corn harvester peeling machine of embodiment one and embodiment two: 1. if the peeling of this example The n pairs of peeling rollers n of machine are selected as five pairs, and then the evenly dividing baffle plates of the evenly distributing mechanism of this example should select four correspondingly. 2. If the number n of peeling rollers is selected as five pairs, the width of the first baffle should be 1 / 5 the length of the peeling roller (that is, the length of 1 / n peeling roller), and the width of the second baffle should be 2 / 5 the length of the peeling roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com