Position sensing chip interface circuit realized based on Tamagawa protocol

A sensor chip and interface circuit technology, which is applied in the field of position sensor chip interface circuit, can solve the problems that the chip slave interface circuit cannot be localized, the integration degree of the application scheme is low, and the price of AU5688 is expensive, etc., so as to improve the overall data Processing capacity, improved system integration, and small product size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical features, circuit configuration, functions and usage scenarios of the present invention intuitive and easy to understand, the present invention will be further explained in conjunction with the illustrations below. In the following expressions, unless otherwise specified, the terms "enable", "connect", " Connection" should be understood in a broad sense.

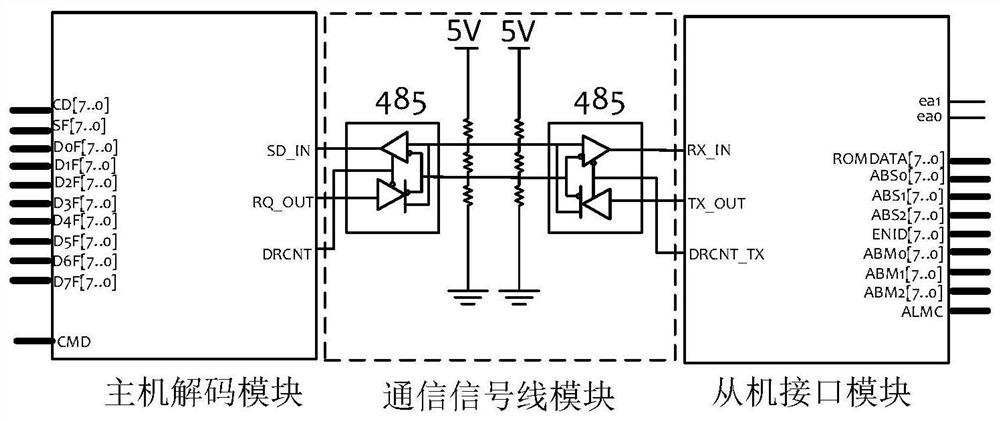

[0024] refer to figure 1 , the invention includes a slave interface module, a communication signal line module and a host decoding module.

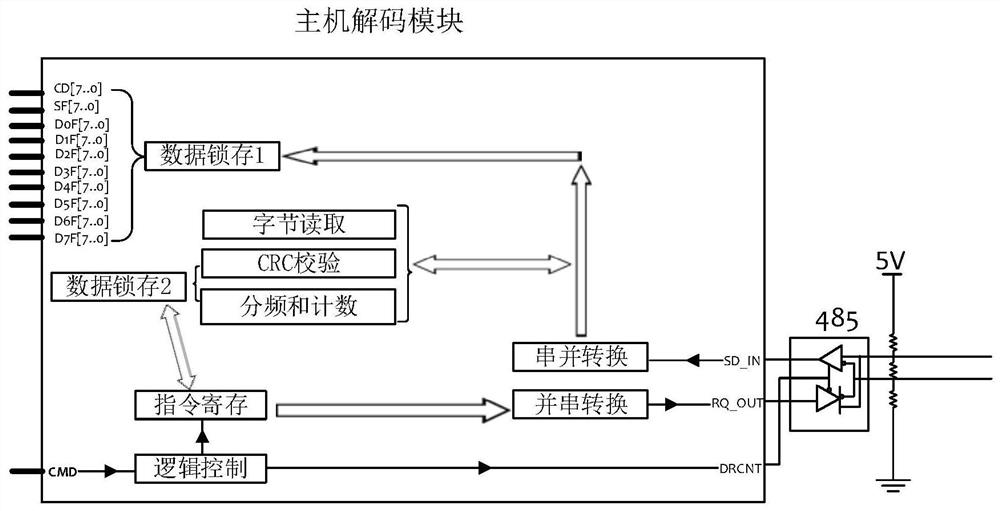

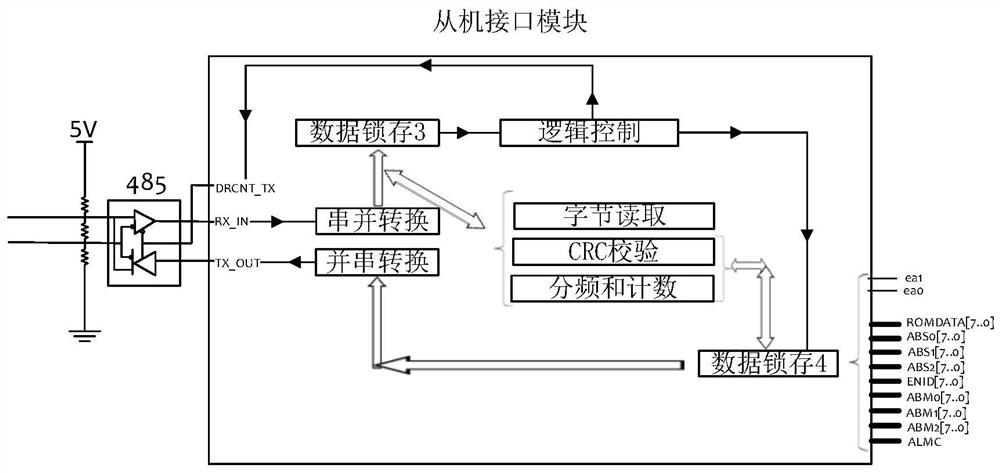

[0025] The input port of the master decoding module is CMD, which is used to specify the command ID type sent by the master to the slave. According to the Tamagawa protocol, it can read single-turn position data, multi-turn data, single-turn data + multi-turn data + chip Alarm information, read EEPROM data, write EEPROM data, the specific ID type is compatible with Tamagawa protocol regulations, output ports CD[7:0], SF[7:0], D0F[7:0], D1F[7:0], D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com