Thick and flat steel turning mechanism for thick and flat steel horizontal gag straightener

A technology of horizontal thick flat steel and straightening machine, which is applied in the field of mechanism of assisting horizontal pressure straightening machine to straighten thick flat steel, which can solve the problems of low localization level, complicated action, and reduced product competitiveness. Achieve the effects of reducing equipment purchase costs, improving the level of localization, and enhancing product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention is capable of various changes in different embodiments without departing from the scope of the present invention, and that the description and drawings therein are illustrative in nature and not limiting. this invention.

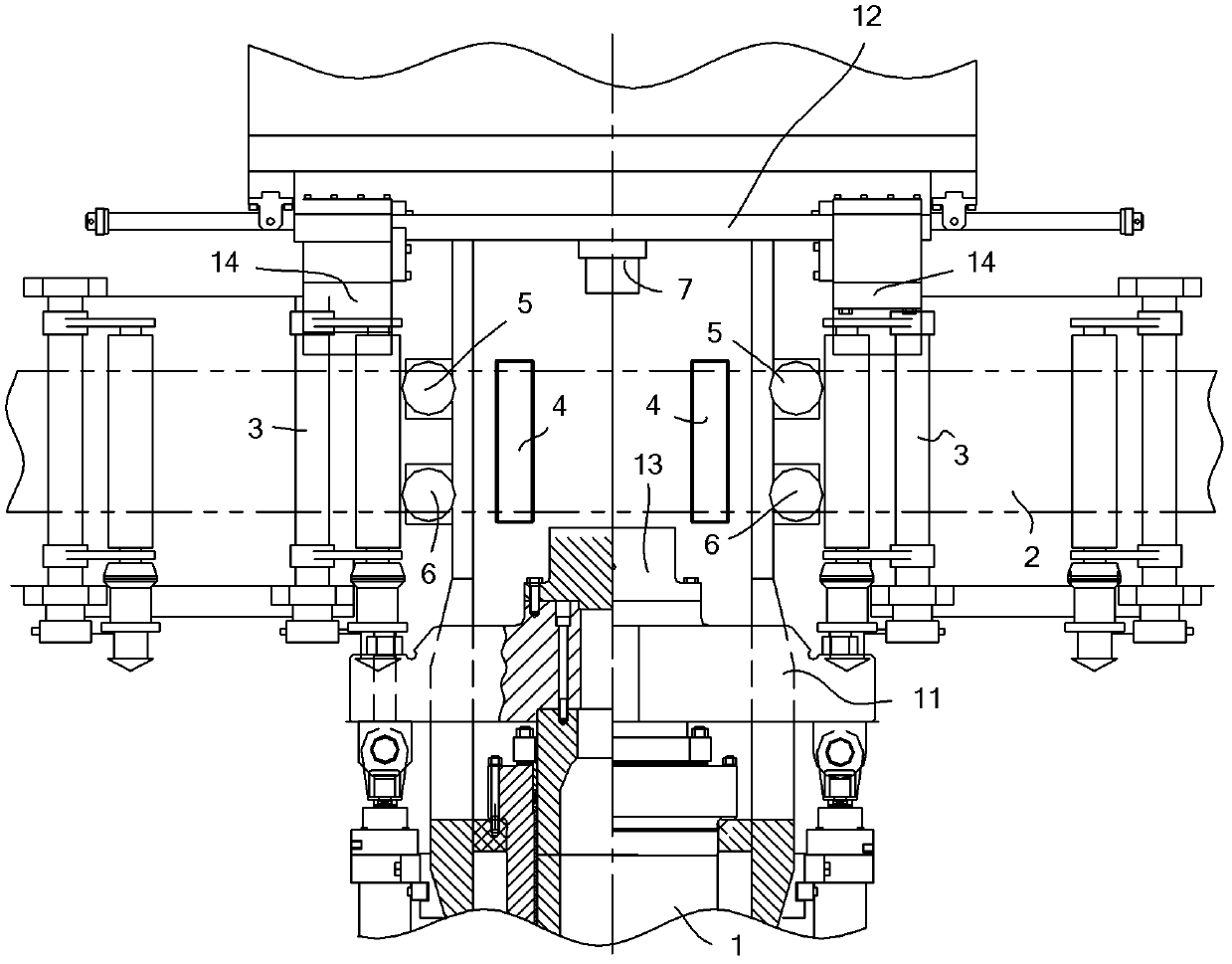

[0015] Such as figure 1 As shown, the horizontal pressure straightening machine 1 includes a straightening machine body frame 11 , a straightening machine body trabecular 12 , a main pressure head 13 of the straightening machine body and two movable fixed pressure heads 14 . Among them, the frame 11 of the straightening machine body is a supporting structure, which provides guarantee for the straightening action; the small beam 12 of the straightening machine body is a beam, which is located in front of the main pressure head 13 of the straightening machine, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com