Improved underground explosion-proof transport truck crane

An improved technology for transporting vehicles, applied in the direction of vehicles with cranes, etc., can solve the problems of unsuitable parts and equipment in bulk, large unloading effect, damage to equipment and components, etc., to solve the difficulty of loading and unloading vehicles, improve efficiency, reduce effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

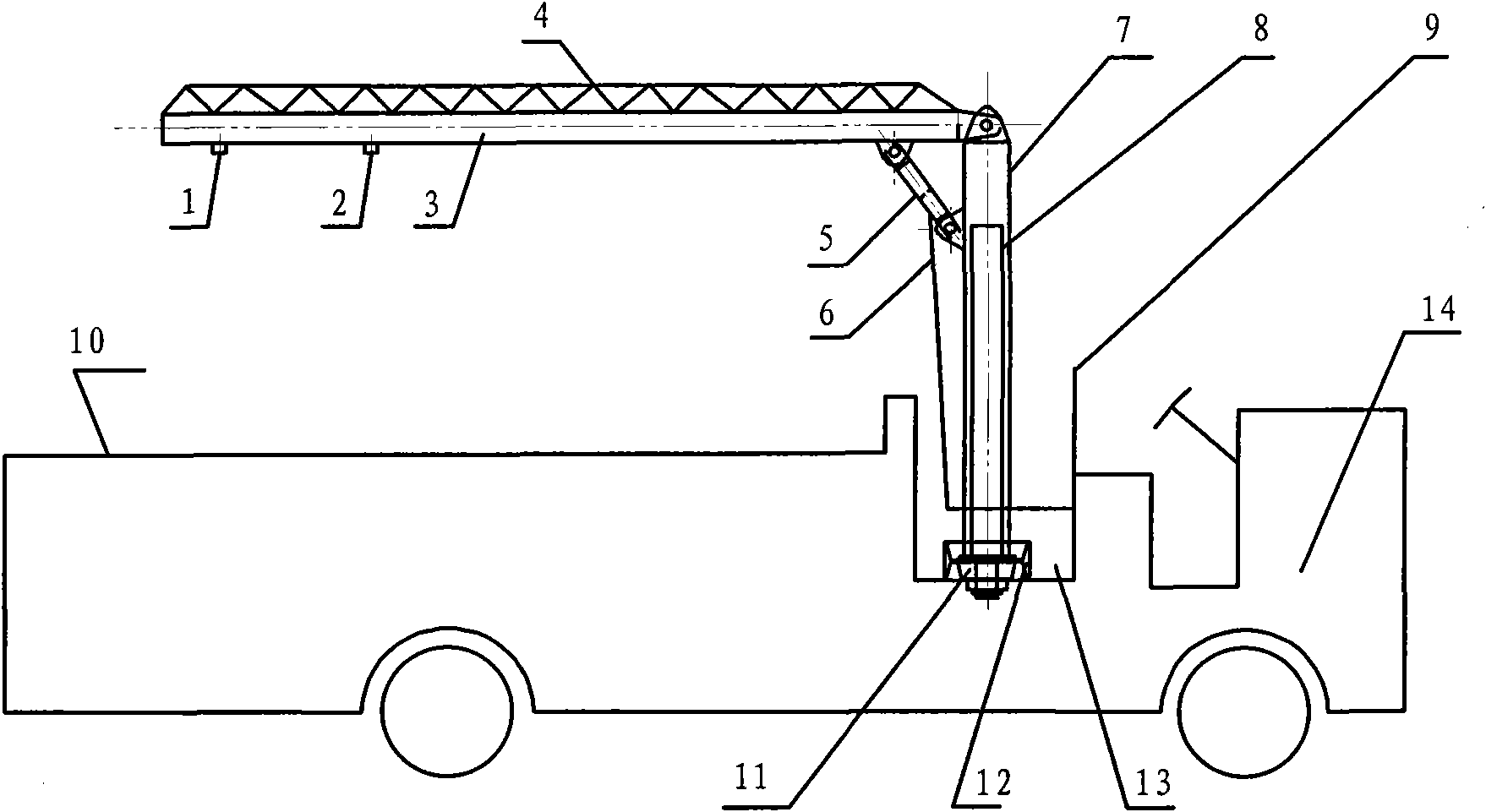

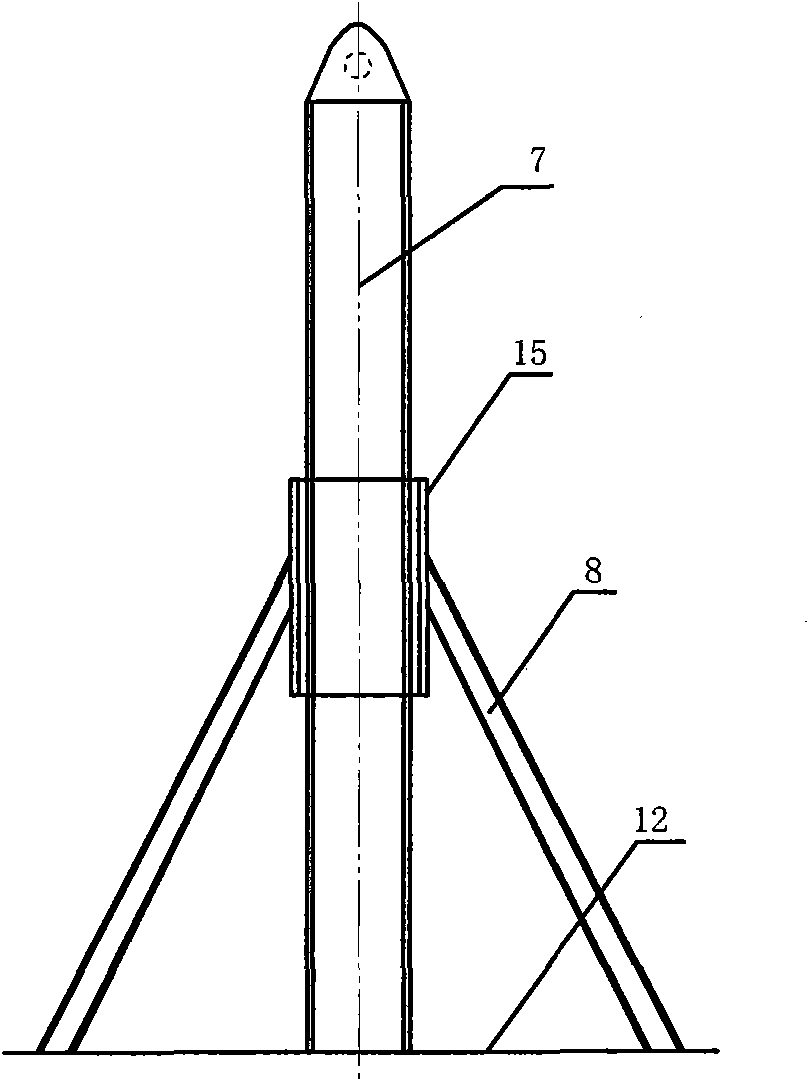

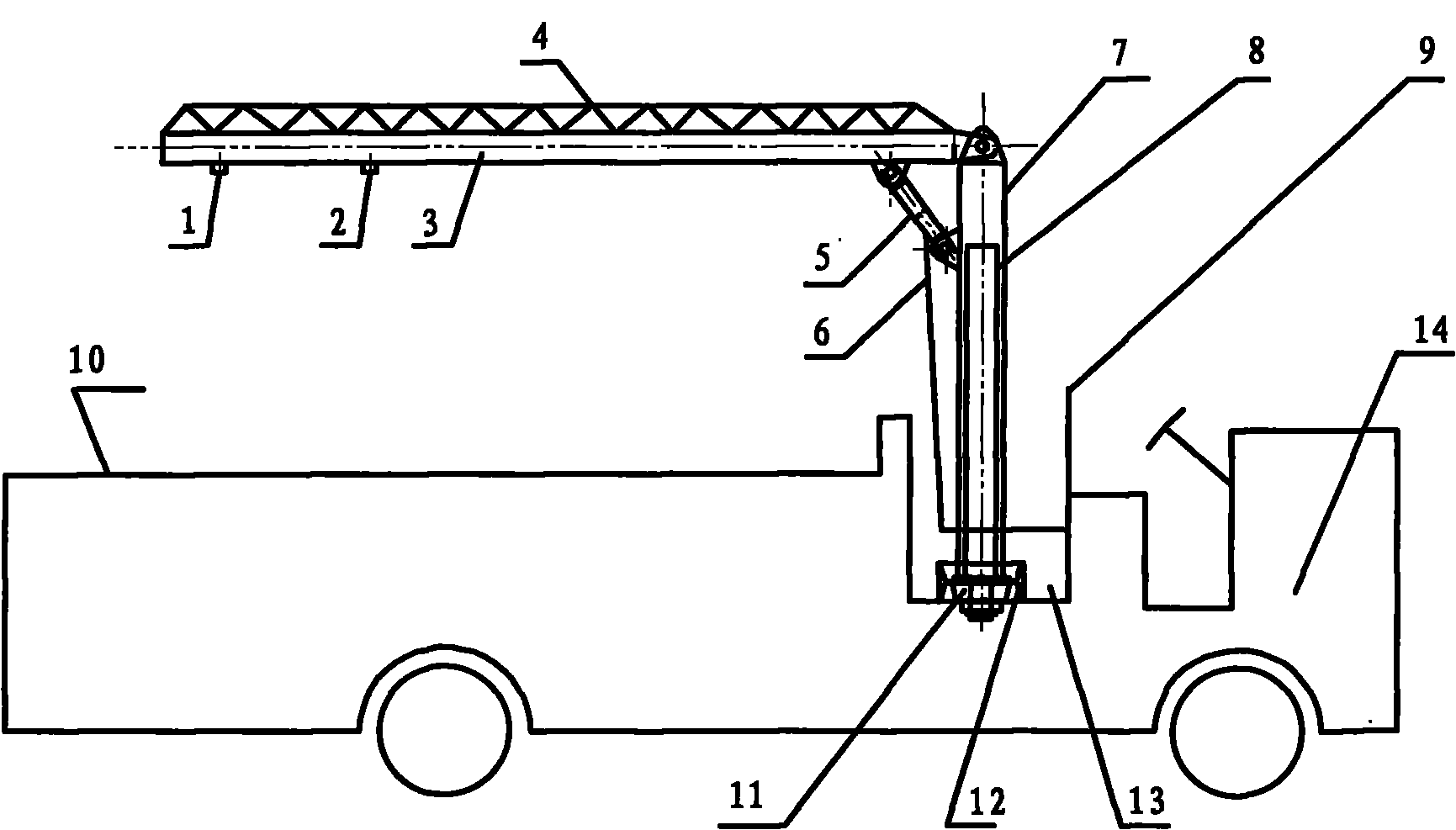

[0010] Embodiment 1: The automobile crane includes a lifting point 1, an angle control point 2, a lifting arm 3, a lifting arm reinforcement rib 4, a hydraulic cylinder 5, an oil pipe 6, a rotating column 7, an anti-tipping column 8, a seat 9, and a carriage 10 , rotating wheel 11, I-beam 12, seat plate 13, engine 14 and sliding sleeve 15, the mine explosion-proof diesel locomotive front end has engine, steering wheel and seat, engine rear portion has compartment, and seat plate is arranged between engine and compartment , an I-beam is connected to the base plate, a rotating wheel is connected to the middle part of the I-beam, the rotating column is connected to the rotating wheel, and one end of the lifting arm is hinged on the upper end of the rotating wheel, and the upper end of the lifting arm is connected with a There are lifting points and angle control points on the lower end of the lifting arm. The lifting points and angle control points are located at the other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com