Method for patterning and coloring surface of cloth

A technology for fabrics and colors, applied in the field of sewing, can solve problems such as unsatisfactory results, increased process steps, and increased equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

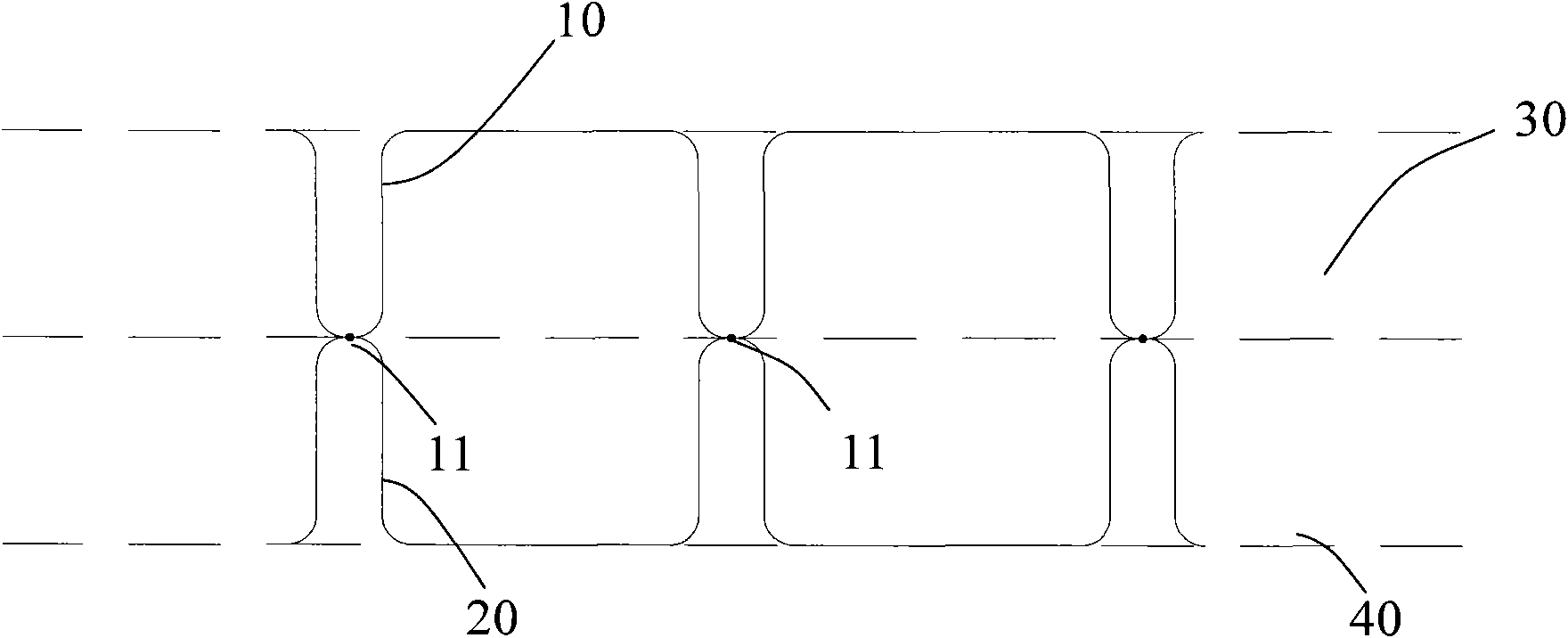

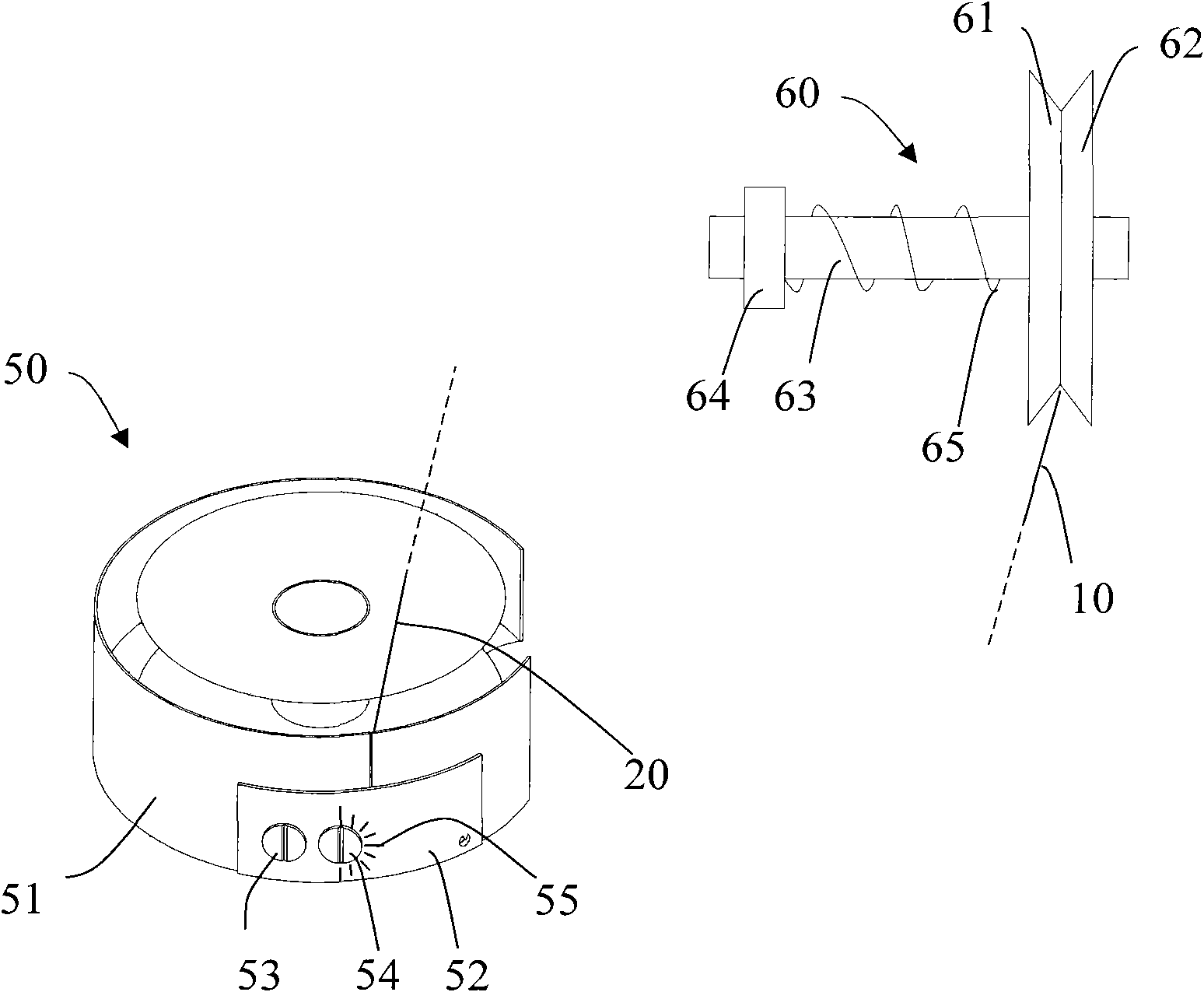

[0025] refer to figure 2 , 3 As shown, in the existing clothing material processing process, the bobbin case 50 and the thread adjustment spring 60 are used to adjust the tightness of the bottom thread 20 and the upper thread 10 respectively, so that the upper thread 10 and the lower thread 20 are intertwined so that the upper clothing material 30 and the lower thread are connected. Clothing 40 sewn together, which further fit image 3 Shown:

[0026] The bobbin case 50 includes a bobbin case body 51, and a thread pressing plate 52 is arranged on the bobbin case body 51. The thread pressing plate 52 is fixed on the bobbin case body 51 by a fixing screw 53, and the thread pressing plate 52 is also provided with an adjusting screw. 54 is used to adjust the tightness of the crimping plate 52. The bottom thread 20 passes under the crimping plate 52, and the tightness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com