Rotary tissue stress culture system and method

A culture system and rotary technology, applied in the field of rotary tissue stress culture system, can solve the problems of limited tissue volume, limited scaffold materials, and inability to use culture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

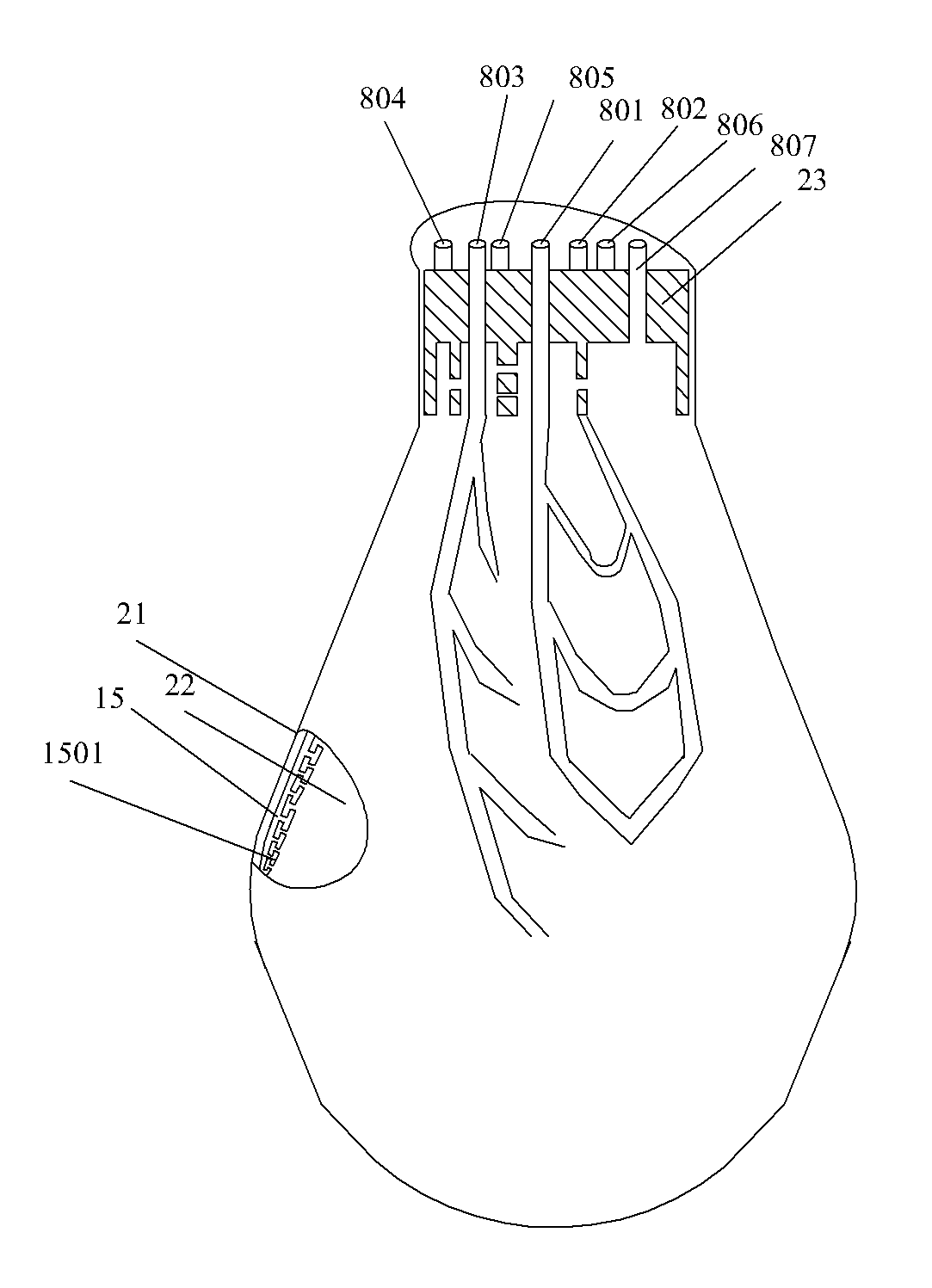

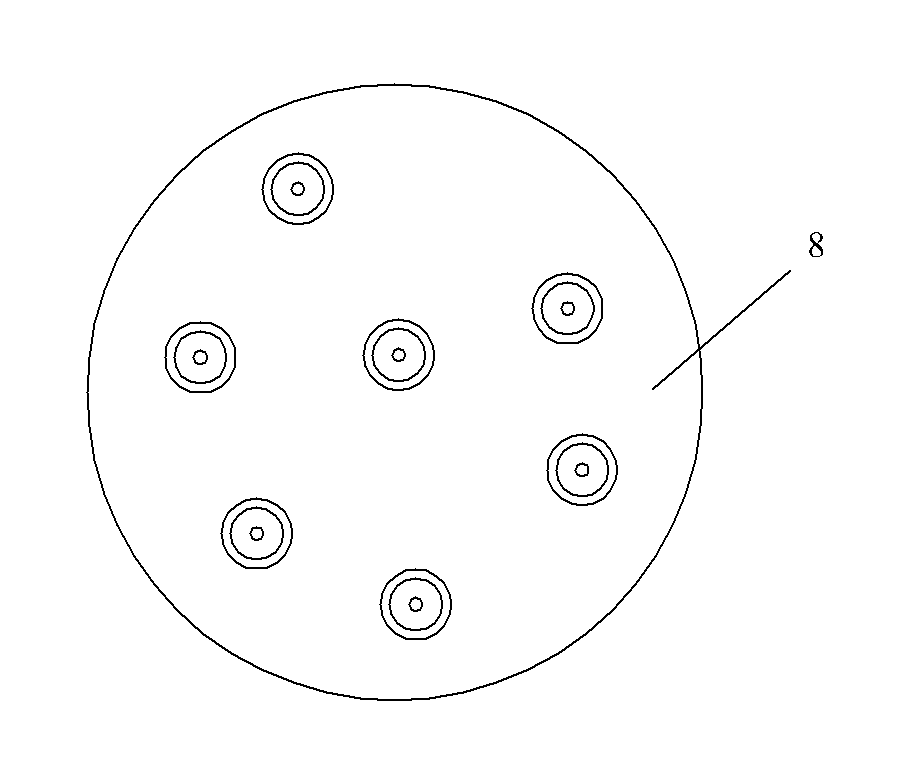

[0028] For an embodiment of a Rotary Tissue Stress Culture System (RTSCS), see figure 1 with figure 2 , including a support 1, on which a culture solution bottle 2, a polyjunction joint 3, an oxygen exchanger 4, a defoamer 5, a constant flow pump 6, a culture solution pressure chamber 7, a multi-channel rotary joint 8, a bottle spinner 9, Peristaltic pump 10, waste liquid bottle 11, rotary bottle hydraulic chamber 12, single-channel rotary joint 13, and control unit 14. The multi-valve joint has three valves called the first valve 301, the second valve 302 and the third valve 303. The inlet of the second valve is connected to the inlet of the third valve, the outlet of the second valve is connected to the outlet of the first valve and simultaneously connected to the oxygen exchanger, the inlet of the first valve is connected to the culture solution bottle, The outlet of the third valve is connected to the waste liquid bottle, the oxygen exchanger is connected to the defoamer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com