Thread ring gauge

A thread ring gauge and thread technology, applied in the direction of ring gauge and measuring gauge, can solve the problems of difficult adjustment and difficult adjustment, and achieve the effect of reducing cost, long service life and avoiding axial deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

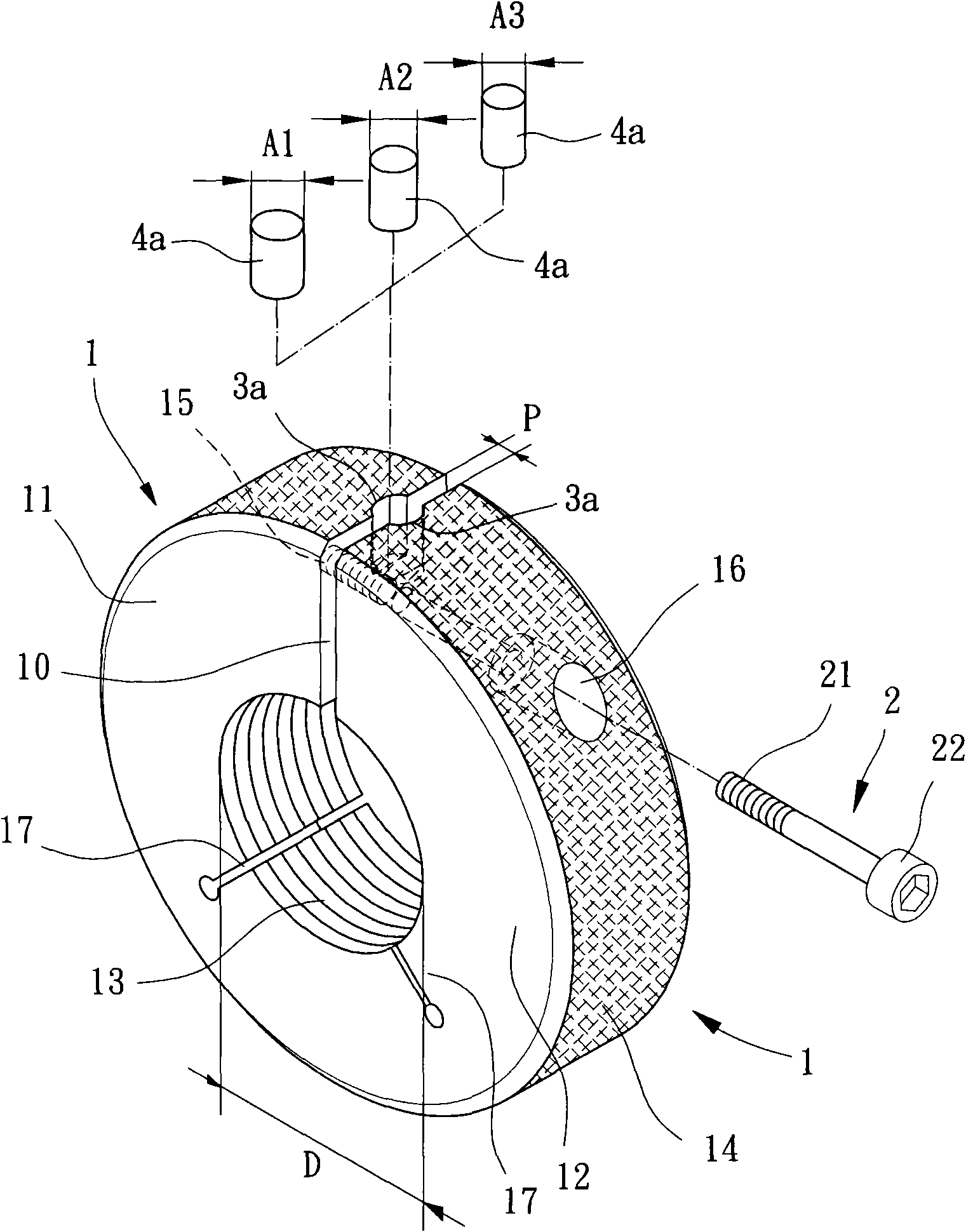

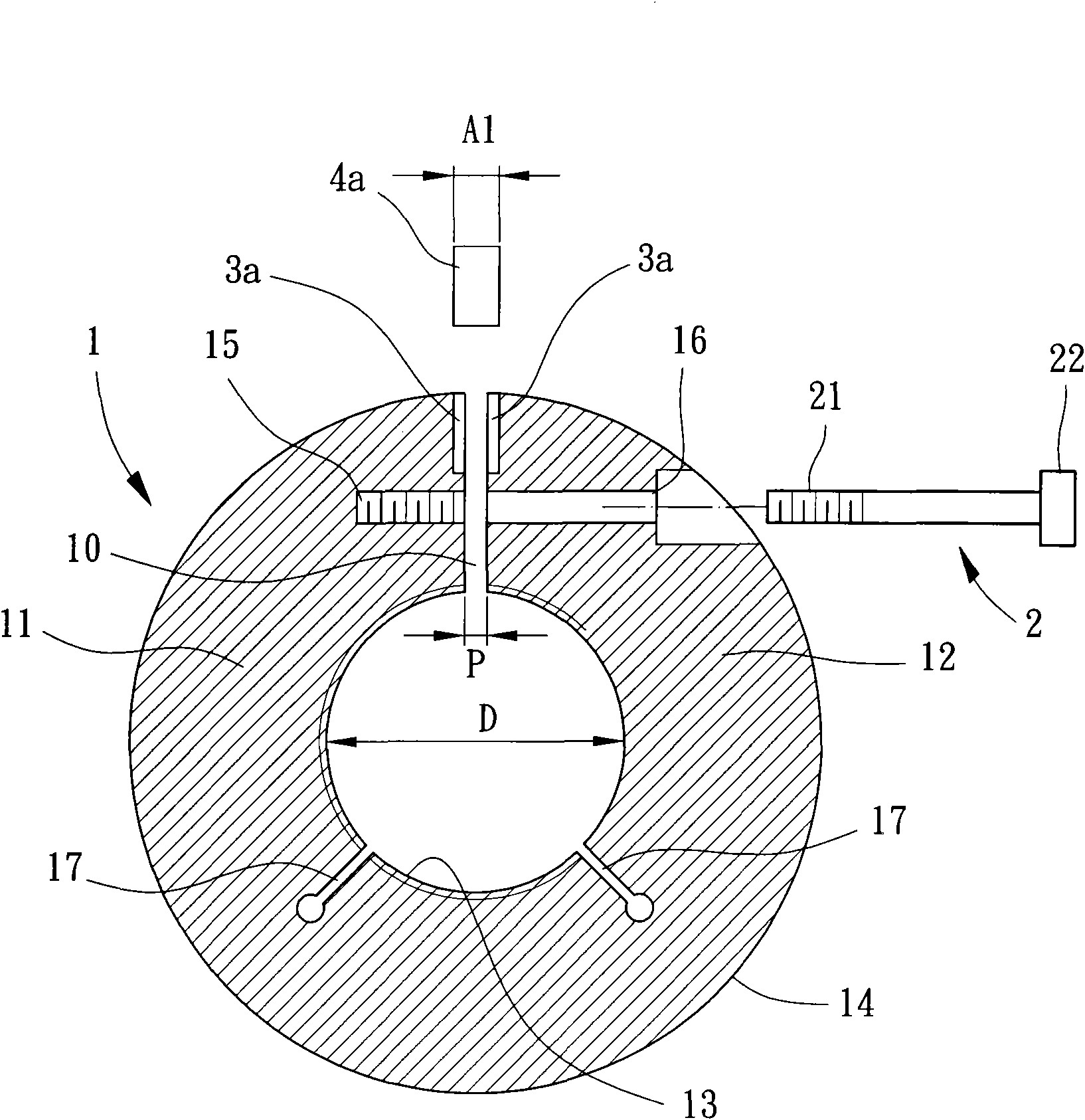

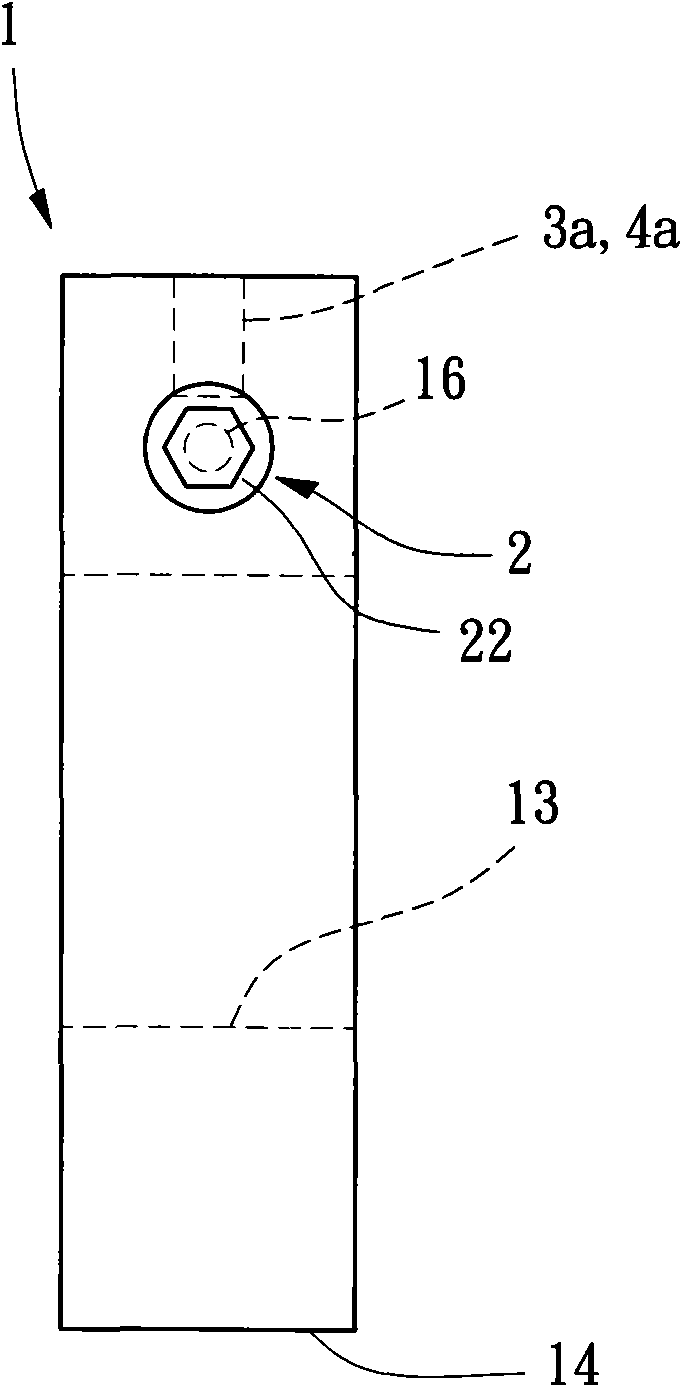

[0035] Please refer to Figures 1 to 3 As shown, the threaded ring gauge of the first embodiment of the present invention includes a body 1 , an adjustment element 2 , at least one positioning groove 3 a and a gauge 4 a.

[0036] The main body 1 is provided with a slit 10 , a first block 11 , a second block 12 , an inner ring surface 13 , an outer ring face 14 , a first hole 15 and a second hole 16 . The body 1 is formed with the first block 11 and the second block 12 by the slit 10, and the slit 10 forms a gap P between the end faces of the first block 11 and the second block 12; The ring surface 13 forms an inner diameter of the inner measuring surface, and the inner ring surface 13 is provided with threads fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap