Electronic device shell and manufacture method thereof

A technology for electronic devices and manufacturing methods, applied in the fields of electrical equipment shells/cabinets/drawers, decorative art, telephone communications, etc., can solve the problems that the shell is not suitable for in-mold decoration molding, etc., and achieve simple manufacturing methods, beautiful shells, Applicable to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

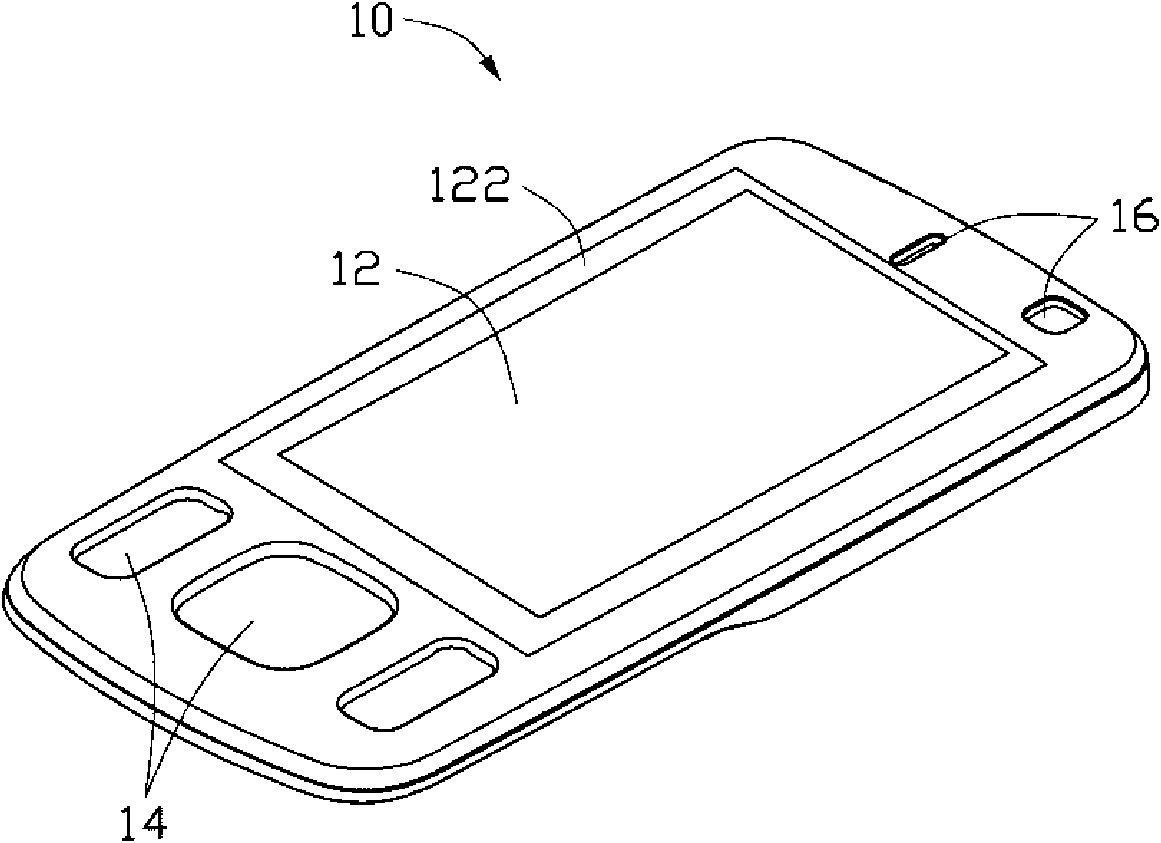

[0017] see figure 1 , a preferred embodiment of the present invention an electronic device casing 10 is formed with a window 12 , a plurality of button holes 14 and a plurality of function holes 16 . The window 12 is in the shape of a rectangular frame. A window ink printing area 122 is formed around the window 12 . The window ink printing area 122 is used to print the window ink layer to form the window 12 . The button hole 14 is formed at one end of the window 12 for assembling a button of an electronic device. The function hole 16 is formed at the other end opposite to the button hole 14, and is used to communicate with the outside world from the functional elements assembled inside the electronic device, such as matching with a camera or a receiver device.

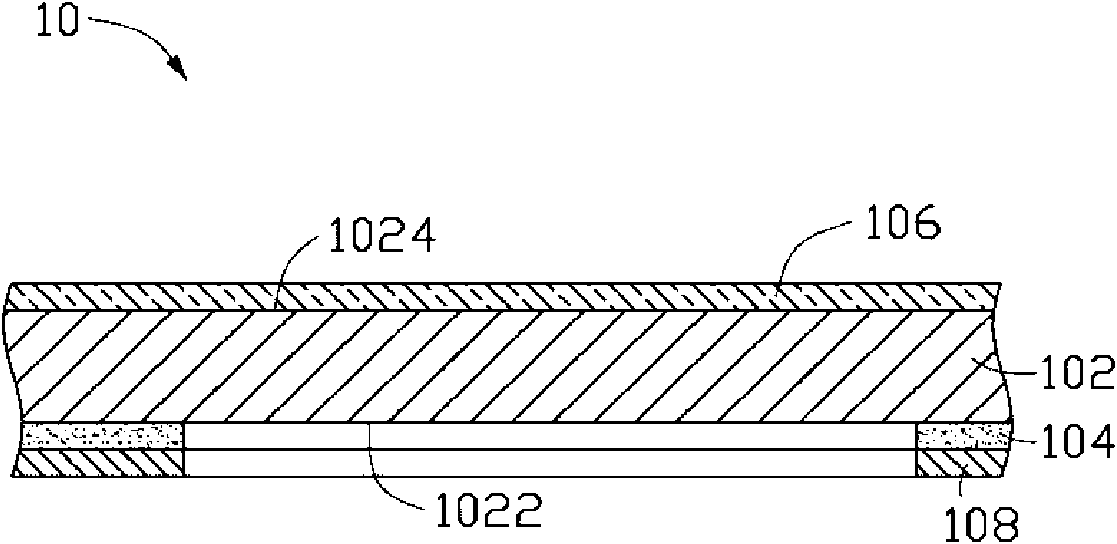

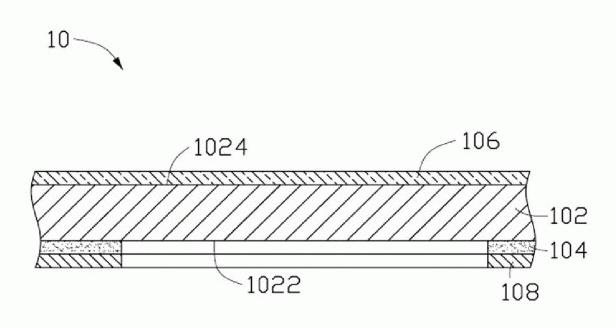

[0018] see figure 2 , the electronic device casing 10 includes a transparent base casing 102 , a window ink layer 104 , a transparent ink layer 106 and a primer layer 108 . The transparent base case 102 is formed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com