Carriage

A trolley and stage technology, which is applied in the field of trolleys for transporting objects, can solve problems such as unsmooth progress and slowness of operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

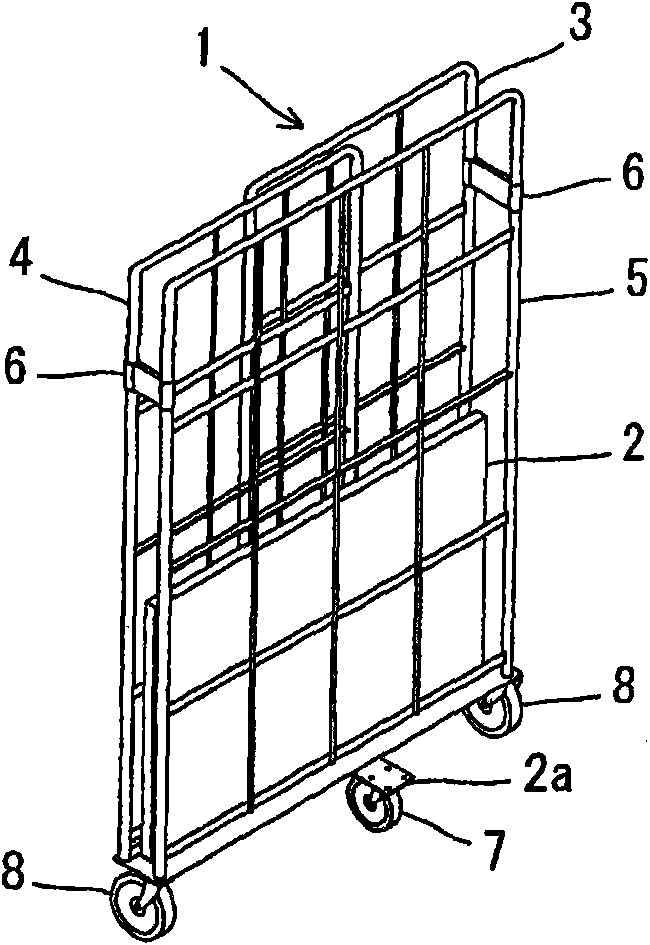

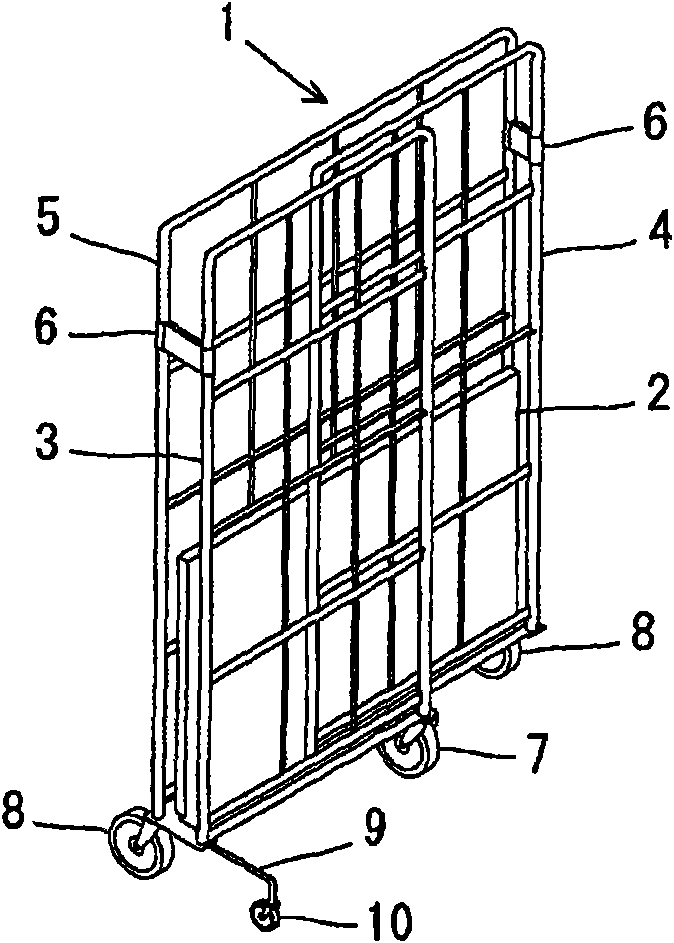

[0048] figure 1 and figure 2 It shows the trolley of this invention, and is a perspective view which shows the folded state of this trolley. figure 1 Represents the state seen from the side of the back frame 5 that becomes the rear side of the trolley, and figure 2 It shows the state viewed from the side of the folded left and right side frames (side frame 3, side frame 4) serving as the front side of the trolley.

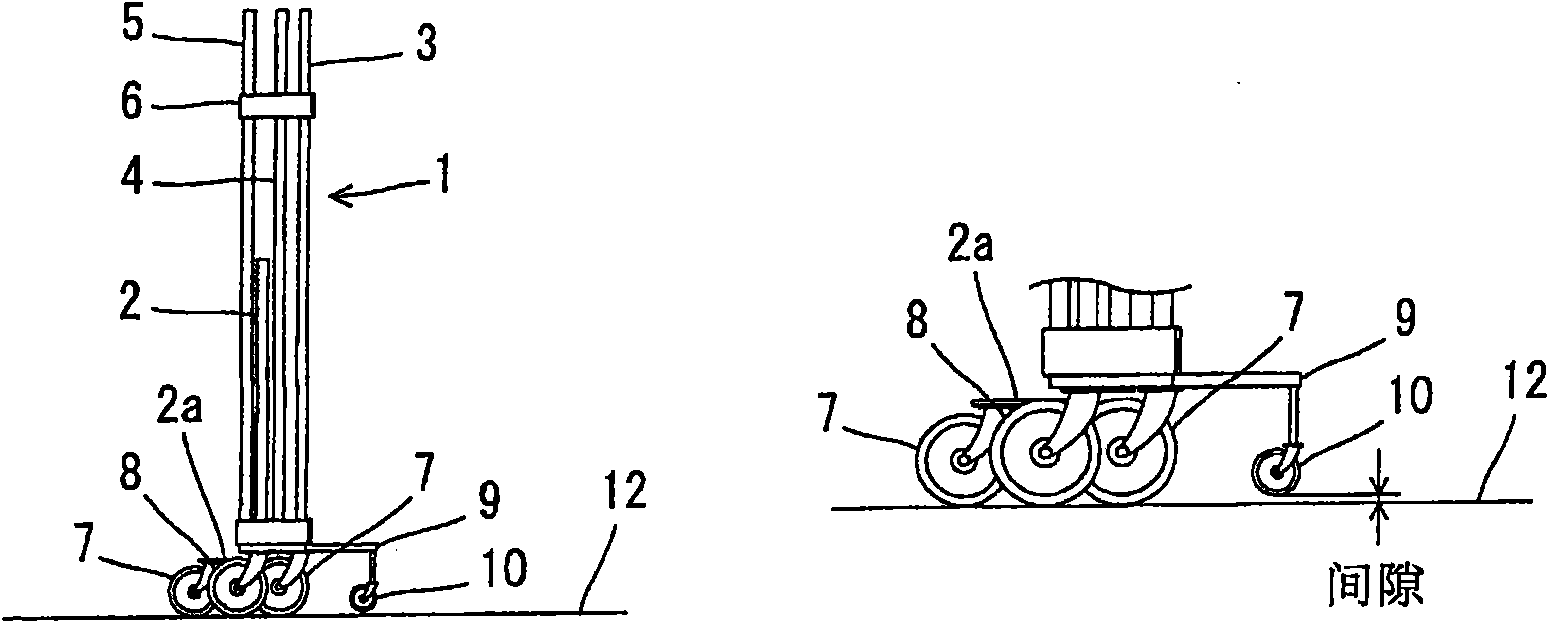

[0049] The trolley 1 is made of the following parts: base plate 2 parts, left and right side frame (side frame 3, side frame 4) parts, back frame 5 parts, front and rear main casters (front side main casters 7, rear side main casters) as wheels for moving. Casters 8), auxiliary casters 10 for making the folded trolley 1 stand on its own safely (cf. figure 2 ).

[0050] according to figure 1 and figure 2 In the folded state of the trolley 1, the bottom plate 2 serving as the loading platform is located in a folded position in a state erected toward the ...

Embodiment 2

[0066] Figure 9 for figure 1 , figure 2 The left and right side frame (side frame 3, side frame 4) parts and back frame 5 parts of the trolley shown are other embodiments composed of plate (side board 3a, side board 4a, back board 5a) parts, and represent the trolley Action diagram of the folding action of .

[0067] in the Figure 9 On the plate parts used to prevent the collapse of the goods provided above the bottom plate 2 of the trolley 1 shown, the side plates 3a and the side plates 4a are respectively freely bendable connected to the side plate 3a and the side plate 4a through the connectors 6a on both sides of the back plate 5a. The back plate 5a side of part 6 is fixed with this back plate 5a, and one side of side plate 3a and side plate 4a is connected via the hinge 6b of connecting piece 6a, therefore, these side plates 3a and side plate 4a can freely rotate via this hinge 6b .

[0068] In addition, the front and rear main casters used as the moving wheels o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com