Pressing mechanism of oil consumption measuring device of vehicle oil tank

A technology of measuring device and pressing mechanism, applied in the direction of buoy liquid level indicator, etc., can solve the problems of easy failure, high manufacturing cost, unfavorable test accuracy, etc., reduce parts and processing and assembly, avoid collision and collision, and simple operation reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

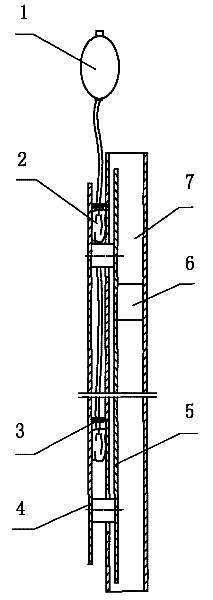

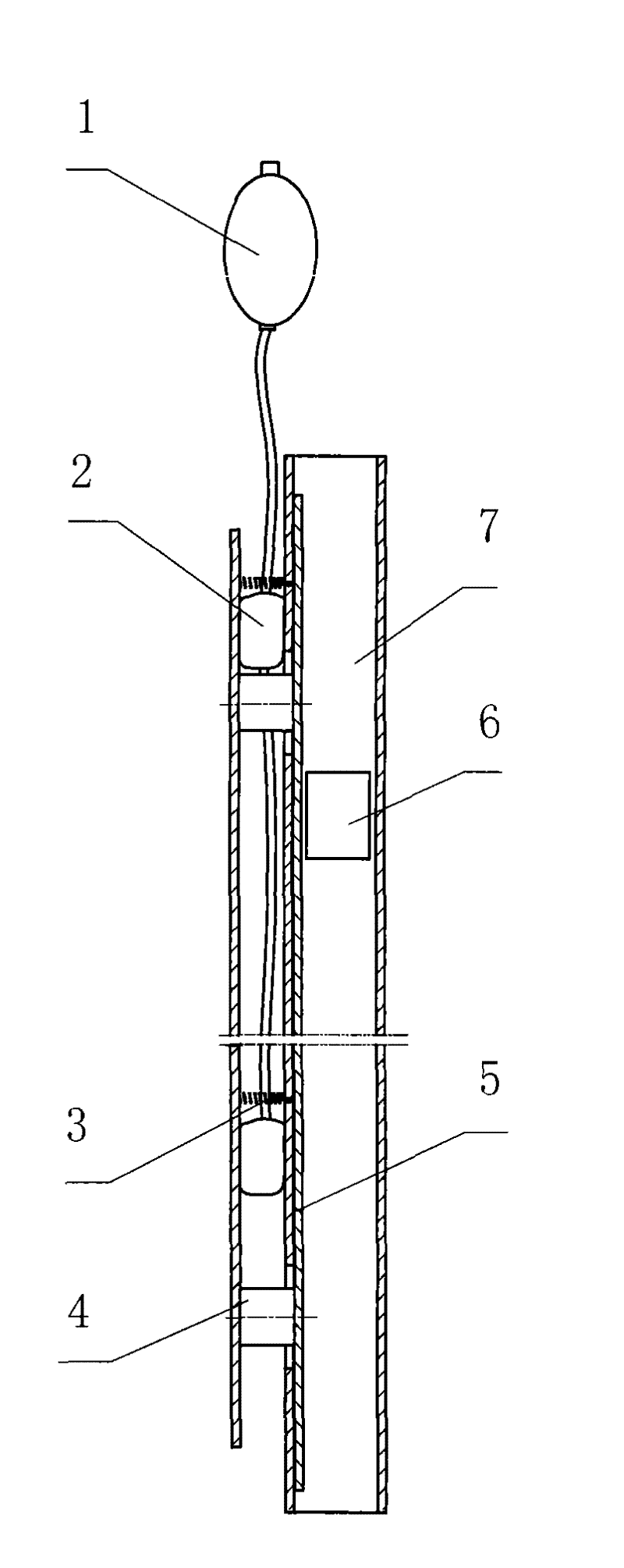

[0030] as attached figure 1 , 2 As shown, a compression mechanism of a vehicle fuel tank fuel consumption measurement device includes an upper hand-held handle and a lower vertical test tube 7. A float 6 is placed in the lumen of the test tube 7, and a compression plate 5 is arranged on the side of the float 6. , the pressing plate 5 can move in the direction perpendicular to the axis of the lumen, in two positions of pressing the float 6 and releasing the float 6, the force of the pressing plate 5 pressing and releasing the float is composed of the spring 3 and the inflation Airbag 2 provided. The side portion of the pressing plate 5 is fixedly connected with a parallel linkage plate 4 , and an inflatable air bag 2 and a tension spring 3 are arranged inside the linkage plate 4 .

[0031] When the air bag 2 is deflated, the pressure plate 5 is pressed in the direction of the tension by the tension of the tension spring, and the float 6 is pressed, positioned in the test tube...

Embodiment 2

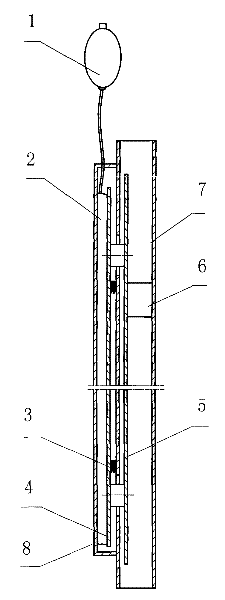

[0034] as attached image 3 , 4 As shown, a compression mechanism of a vehicle fuel tank fuel consumption measurement device includes an upper hand-held handle and a lower vertical test tube 7. A float 6 is placed in the lumen of the test tube 7, and a compression plate 5 is arranged on the side of the float 6. , the pressing plate 5 can move in the direction perpendicular to the axis of the lumen, in two positions of pressing the float 6 and releasing the float 6, the force of the pressing plate 5 pressing and releasing the float is composed of the spring 3 and the inflation Airbag 2 provided. The side portion of the pressing plate 5 is fixedly connected with a parallel linkage plate 4 , an inflatable air bag 2 is arranged outside the linkage plate 4 , and an elastic force spring 3 is arranged inside the linkage plate 4 .

[0035] When holding the inflatable ball 1 at the handle, repeatedly pressing the inflatable ball 1 to inflate the inflatable air bag 2, the volume of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com