Methods and devices for surveying elevator hoistways

A shaft and electronic measurement technology, applied in the direction of measuring devices, optical devices, transportation and packaging, etc., can solve problems such as time-consuming, costly and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Wherever possible, the same or like reference numbers will be used throughout the drawings to refer to the same or like parts.

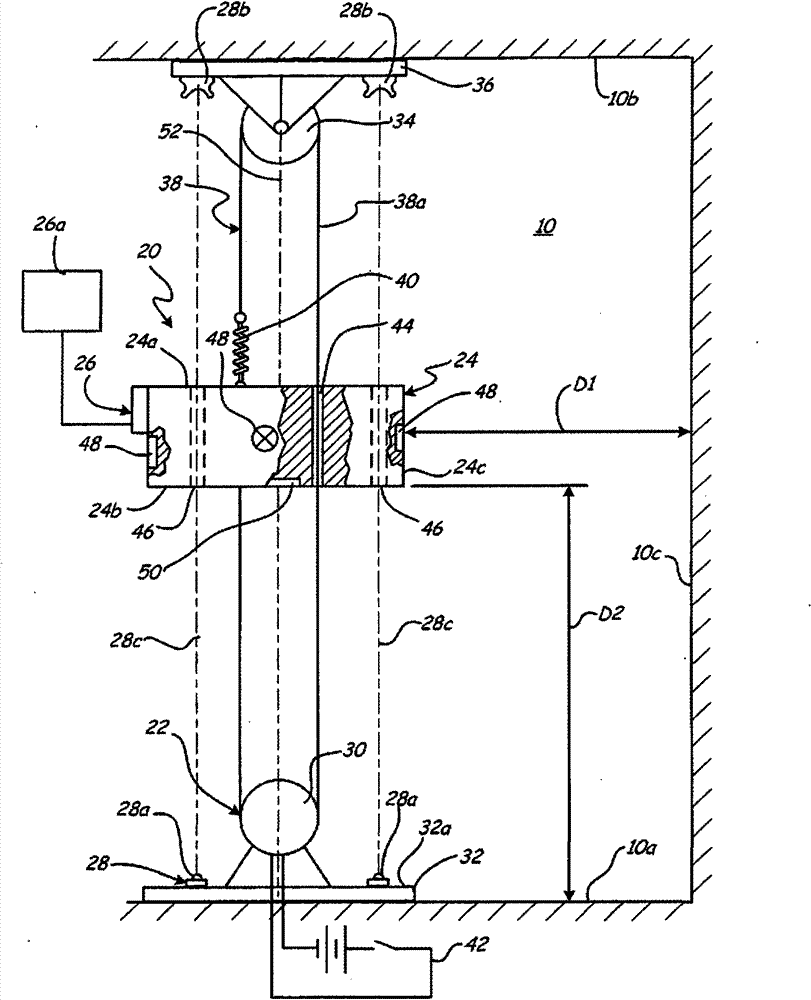

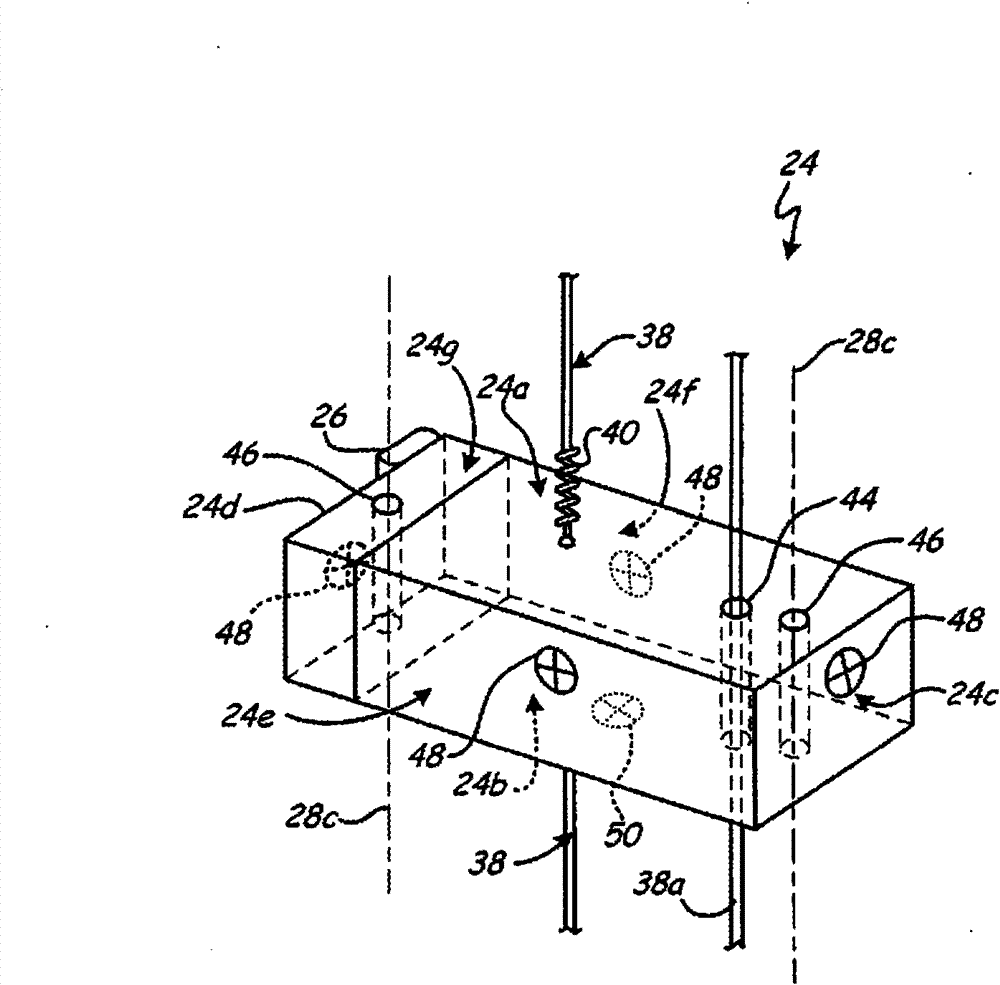

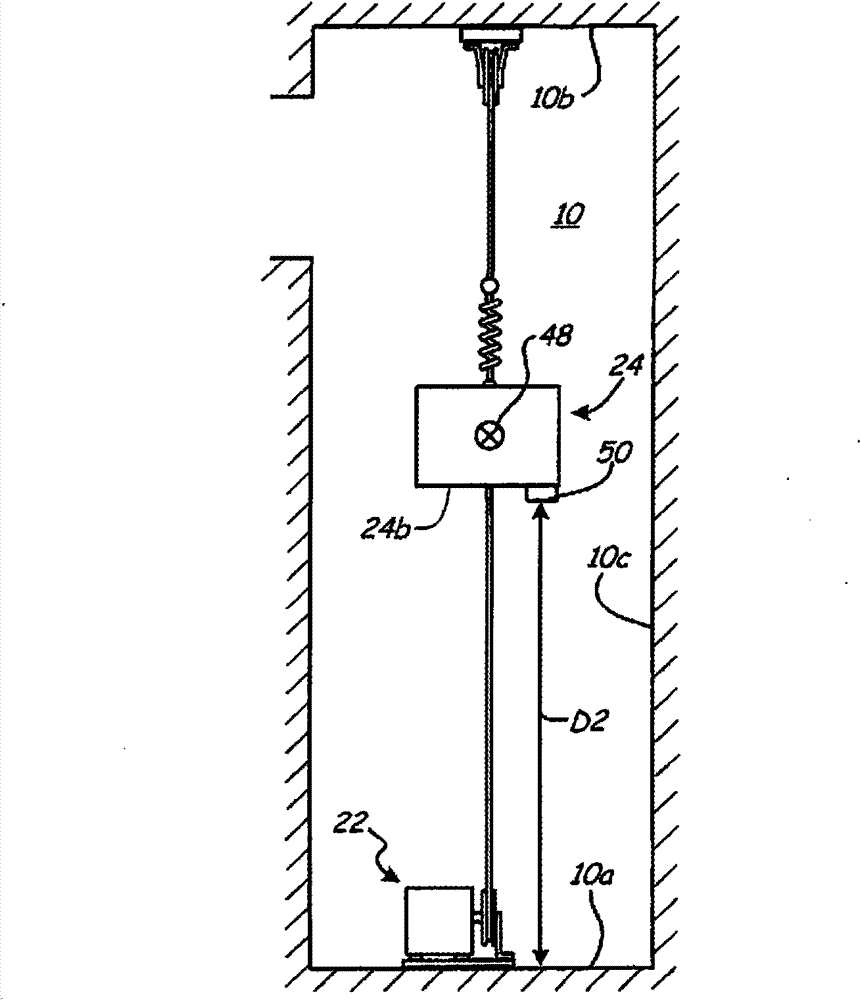

[0016] figure 1 is a front view of a structure in the form of an elevator shaft 10 and a shaft survey system 20 according to the invention. The hoistway survey system 20 includes a conveyor 22 , a platform such as an electronic measurement device (EMD) 24 , an electronic controller 26 , and an optical alignment system 28 . exist figure 1 , EMD 24 may be connected to conveyor 22 , and conveyor 22 may be configured to pass EMD 24 through hoistway 10 . As the EMD 24 passes through the hoistway 10, the EMD 24 may be configured to measure distances, such as the lateral distance D1 between the side 24c of the EMD 24 and the wall 10c of the hoistway 10 and the longitudinal distance D2 between the bottom 24b of the EMD 24 and the bottom 10a of the hoistway. Electronic controller 26 may be coupled to EMD 24 and configured to store and / or transmit me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com