Lens for high-power LED road lighting lamp

A lighting fixture and high-power technology, which is applied in the field of lenses for high-power LED road lighting fixtures, can solve the problems of small illumination angle, easy movement of the lens, large dark area, etc. The effect of lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings.

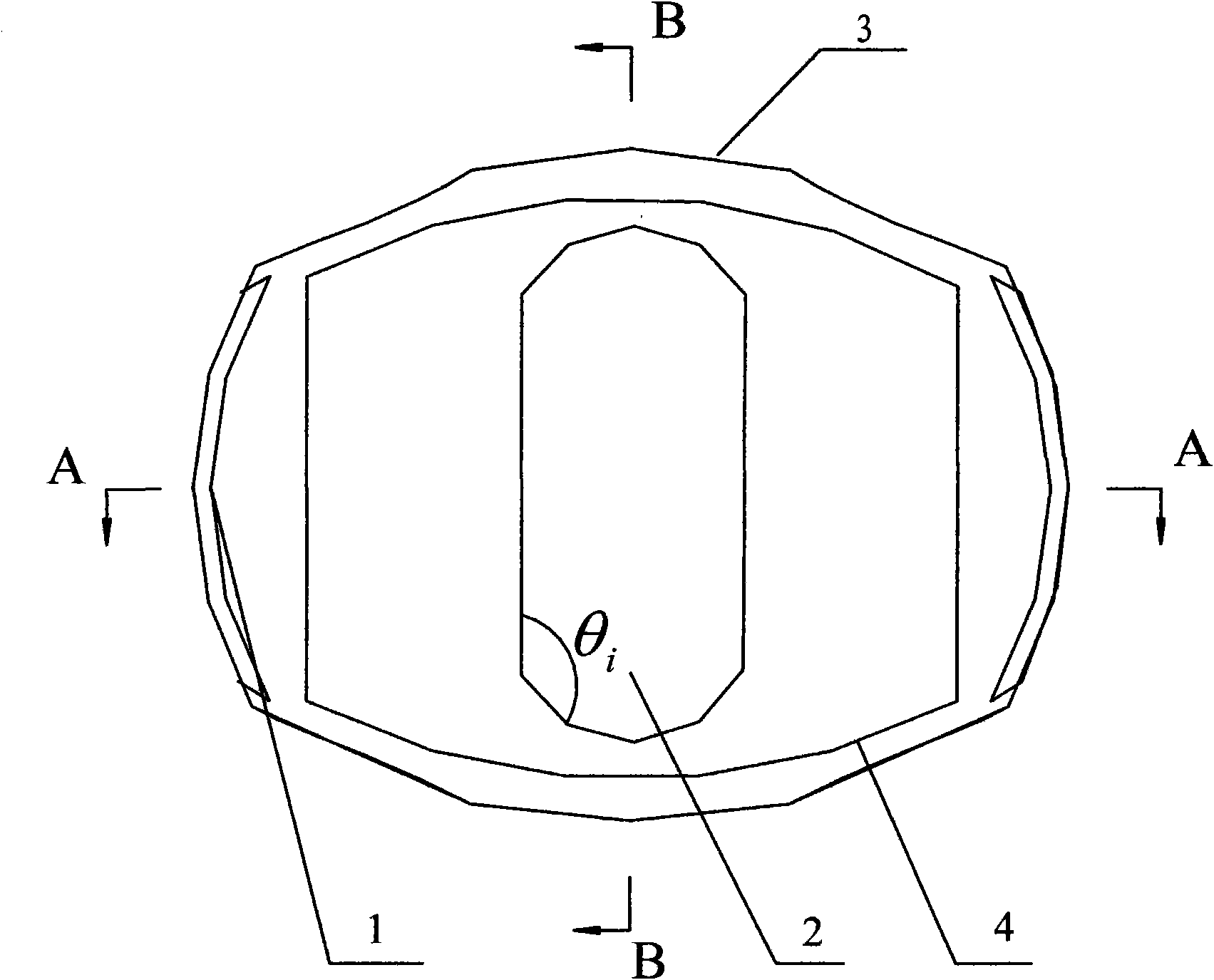

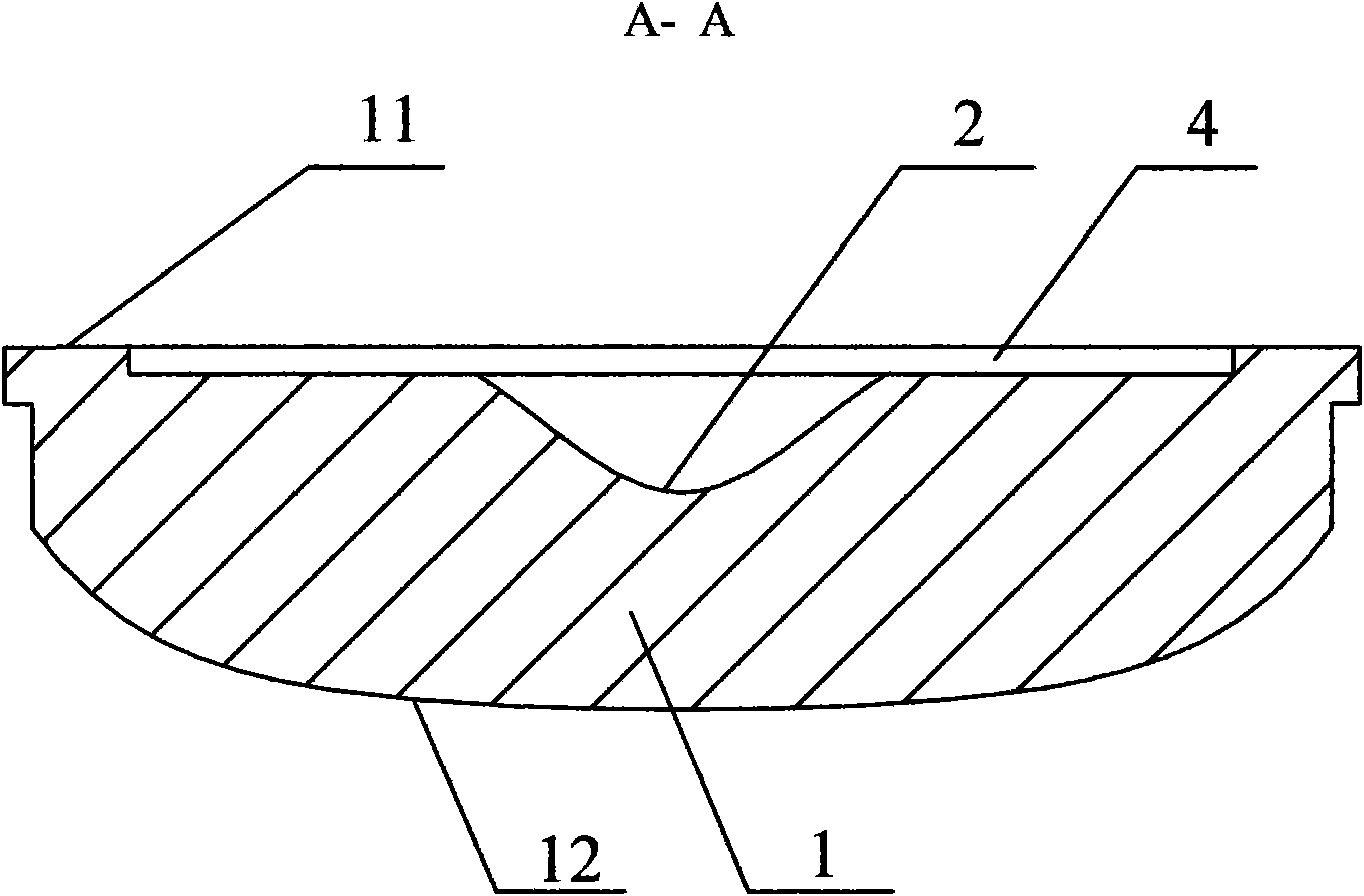

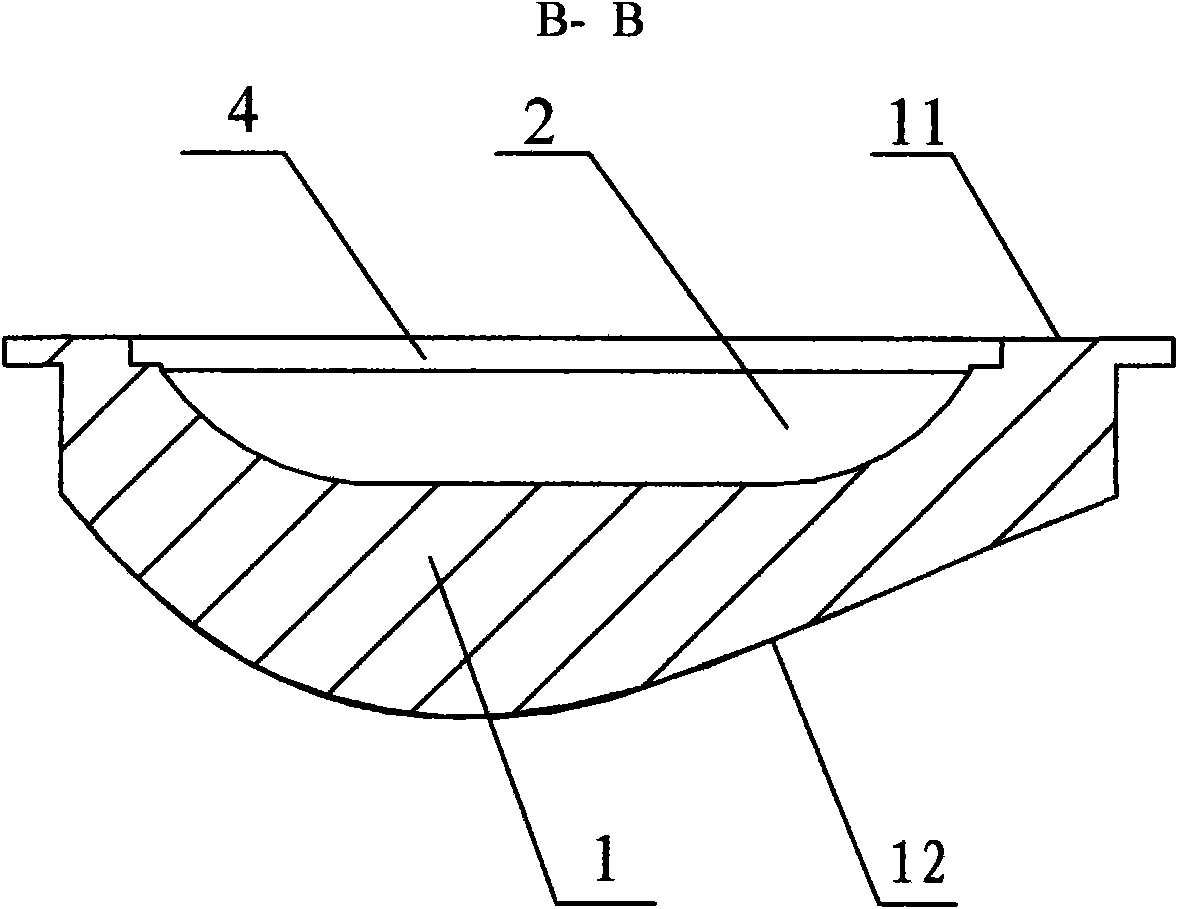

[0016] Such as Figure 1 to 3 As shown, the lens for high-power LED road lighting fixtures of the present invention relates to an LED light source chip, including a lens body. The surface of the lens body includes an arc curved surface and a plane. The center of the arc curved surface is provided with only a symmetry plane, and The lens body is provided with a positioning groove for positioning and installing the LED light source chip on its plane, the positioning groove is adapted to the LED light source chip, and the center of the positioning groove coincides with the center of the lens, and at the same time is in the plane center of the lens body Set long grooves on the light-receiving surface.

[0017] In addition, both ends of the long groove on the light-receiving surface are curved surfaces, and the middle part is a flat surface, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com