Clamping device

A clamping device and clamping element technology, which is applied in transportation and packaging, textiles and papermaking, and thin material processing, can solve the problems of yarns not being clamped, yarns not being clamped sufficiently and firmly, etc., to achieve The effect of extending the time window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

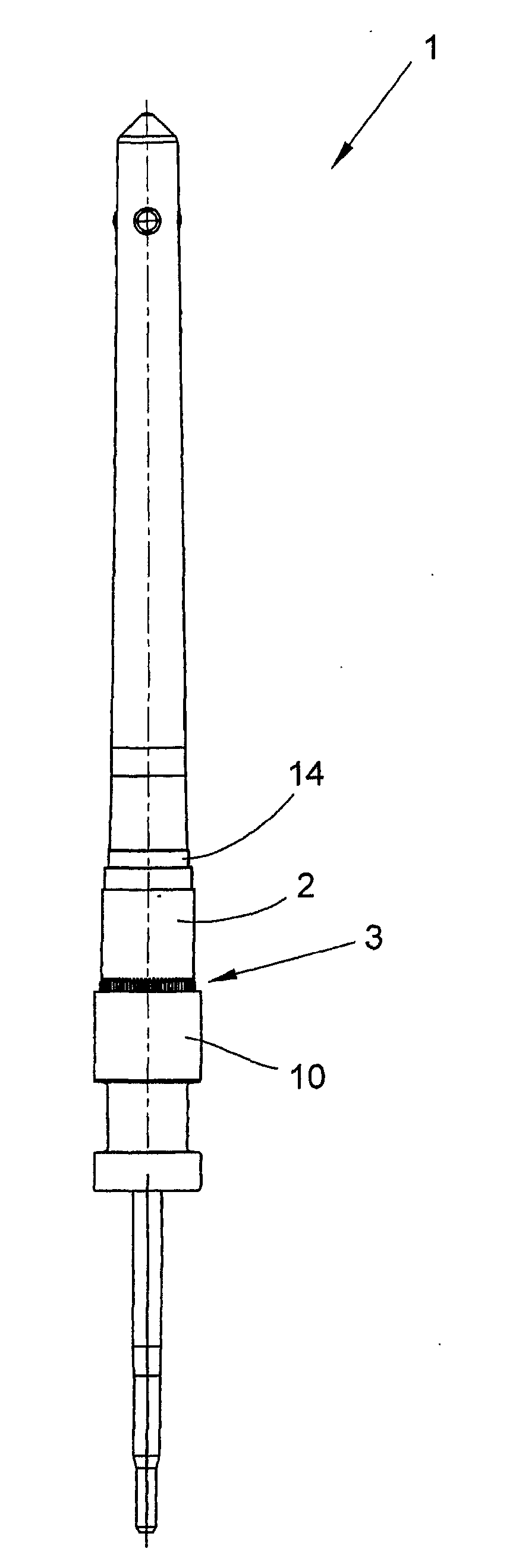

[0023] figure 1 Shown is a spindle top 1 of a spindle of a textile machine, in particular a spinning spindle and a twisting spindle. The spindle upper part 1 has a shank made of metal for receiving a sleeve, not shown, on which the yarn is to be wound into a bobbin. For this purpose, a spinning ring, not shown, is provided on the spindle top 1, which surrounds the spindle top 1 concentrically and on which a traveler turns, which deflects the yarn to the sleeve and Wrapped on sleeve. A driving roller 2 is arranged on the spindle upper part 1, and the spindle upper part 1 can be driven by the driving roller 2 during the operation of the spinning machine.

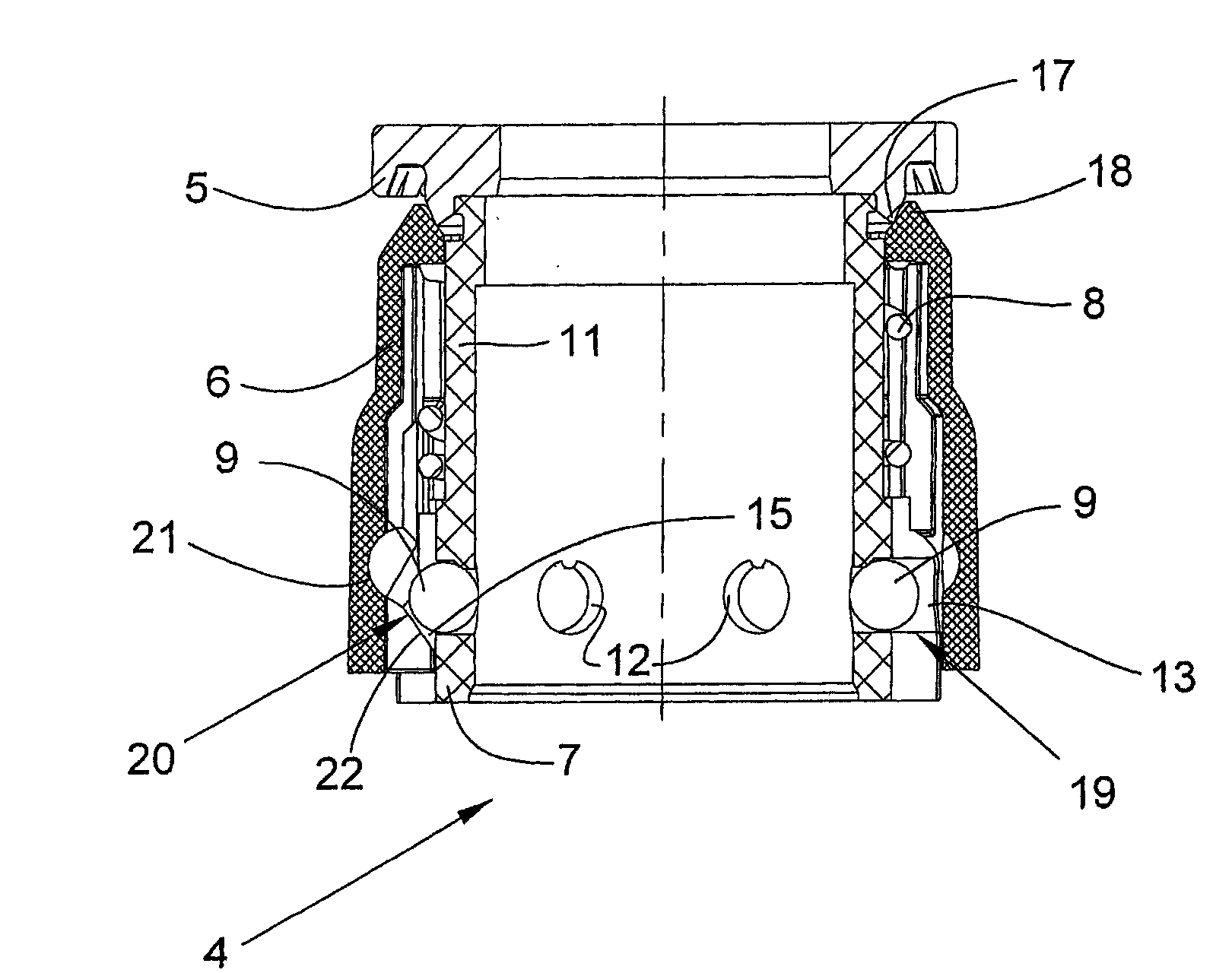

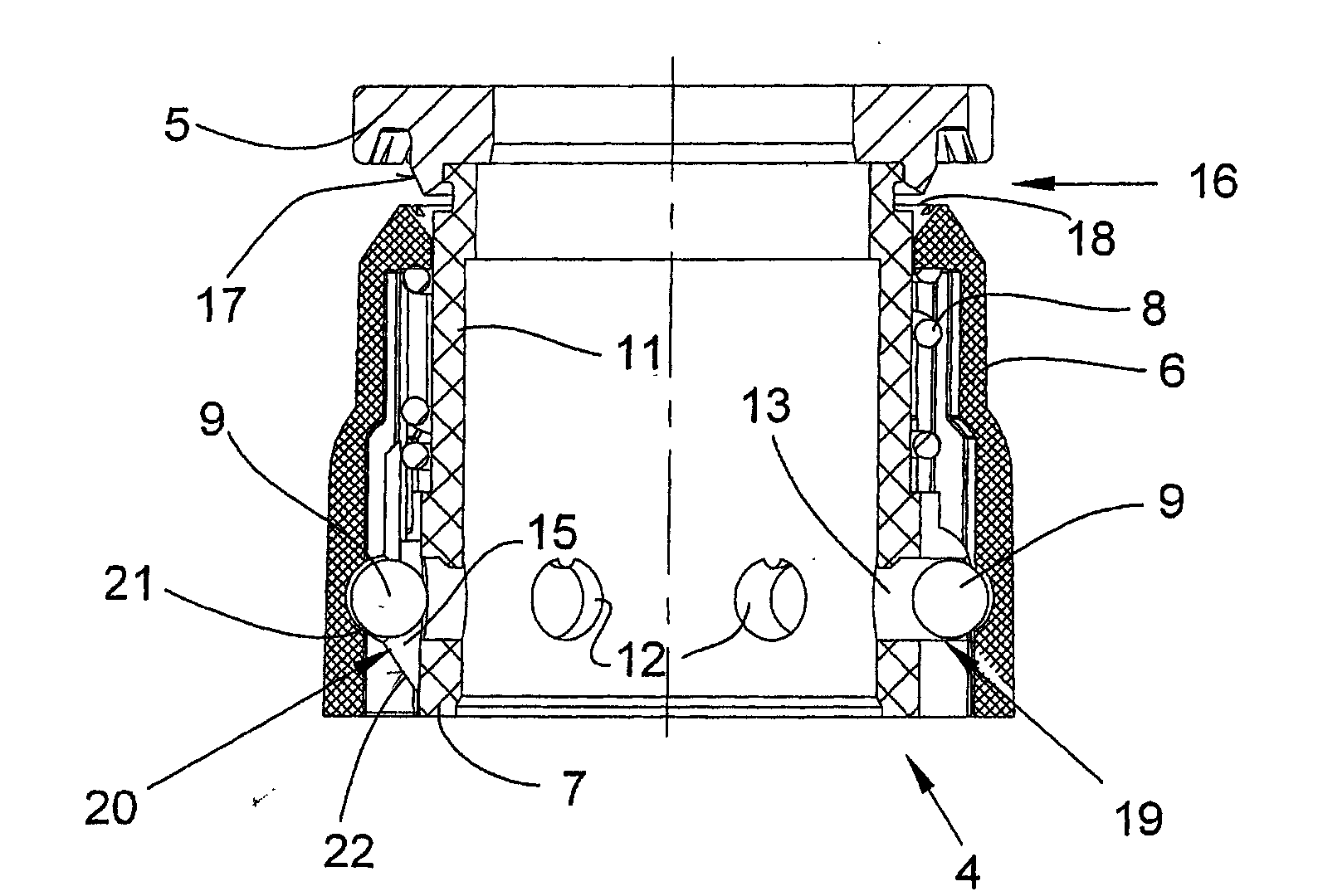

[0024] The drive roller 2 has a cooperating portion 14 for fixing the clamping device 4 according to the invention for clamping the yarn when the produced cop is doffing. The clamping device 4 is actuated by centrifugal force and can be in two positions - a clamped position and an open position, as in figure 2 The yarn is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com